What Tests are Required for Medical Devices?

The testing of medical devices is a broad and comprehensive field covering multiple key aspects to ensure the safety, effectiveness, and compliance of medical devices. In this article, JJR Laboratory in China discusses the common testing contents included in medical device testing reports.

Physical Performance Testing

1. Size and Appearance Inspection: Confirm whether the size, shape, and appearance of the medical device meet the design requirements and check for any obvious defects or damage.

2. Mechanical Performance Testing: Evaluate the mechanical strength and stability of the medical device, such as tensile, compression, bending, and torsion tests, to ensure it does not break or fail under normal use conditions.

3. Operational Performance Evaluation: Test the operational performance of the medical device, such as buttons, switches, and adjustment devices, to ensure they are easy to operate and comply with ergonomic principles.

Chemical Performance Testing

1. Material Chemical Analysis: Conduct chemical composition analysis of the materials used in the medical device to ensure their safety and stability.

2. Harmful Substance Detection: Detect the presence of harmful components such as heavy metals and toxic substances in the medical device to ensure it does not pose a hazard to human health.

ISO 10993 Biocompatibility Testing

1. Skin Irritation Testing: Evaluate whether the medical device causes irritation or allergic reactions when in contact with the skin.

2. cytotoxicity testing: Detect the cytotoxicity of the medical device and assess its impact on cell growth and reproduction.

3. Implantation Testing: For medical devices that need to be implanted in the human body, conduct long-term implantation tests to evaluate their compatibility with surrounding tissues.

IEC 60601 Electrical Safety Testing

1. Insulation Resistance Testing: Ensure that the electrical parts of the medical device have sufficient insulation performance to prevent the risk of electric shock.

2. Leakage Current Testing: Detect whether the medical device has excessive leakage current during operation to ensure safe use.

Microbiological Testing

1. Sterility Testing: Confirm whether the medical device meets sterility standards during production and packaging to prevent microbial contamination.

2. Bioburden Testing: Detect the bioburden level of the medical device, i.e., the number and types of microorganisms, to evaluate its cleanliness.

Stability and Shelf Life Testing

1. Accelerated Aging Testing: Simulate the aging process of the medical device during long-term use to assess its stability and service life.

2. Shelf Life Verification: Determine the shelf life of the medical device under specific storage conditions to ensure its performance remains stable within the shelf life.

Packaging and Labeling Inspection

1. Packaging Integrity Testing: Ensure that the packaging materials of the medical device have good sealing and protective performance to prevent damage during transportation and storage.

2. Label and Marking Inspection: Verify whether the labels and markings of the medical device comply with relevant regulations and standards, including clear and accurate information on the product name, model, production date, and usage instructions.

These testing contents cover various stages from design to production and from raw materials to finished products, aiming to ensure the quality and safety of medical devices and protect patients' interests. Specific testing items may vary depending on the type, purpose, and regulatory requirements of the medical device.

Email:hello@jjrlab.com

Write your message here and send it to us

What is the 4.3 Toxicology Test in ASTM F963?

What is the 4.3 Toxicology Test in ASTM F963?

What is the Canada Tent SOR/2024-217 Test Report?

What is the Canada Tent SOR/2024-217 Test Report?

How to get the Amazon AS/NZS 1900 Test Report?

How to get the Amazon AS/NZS 1900 Test Report?

Children's Jewelry CPC Certification and ASTM F292

Children's Jewelry CPC Certification and ASTM F292

Amazon Ladder Compliance Certification Guide

Amazon Ladder Compliance Certification Guide

Amazon and Temu Require FCM Test Reports

Amazon and Temu Require FCM Test Reports

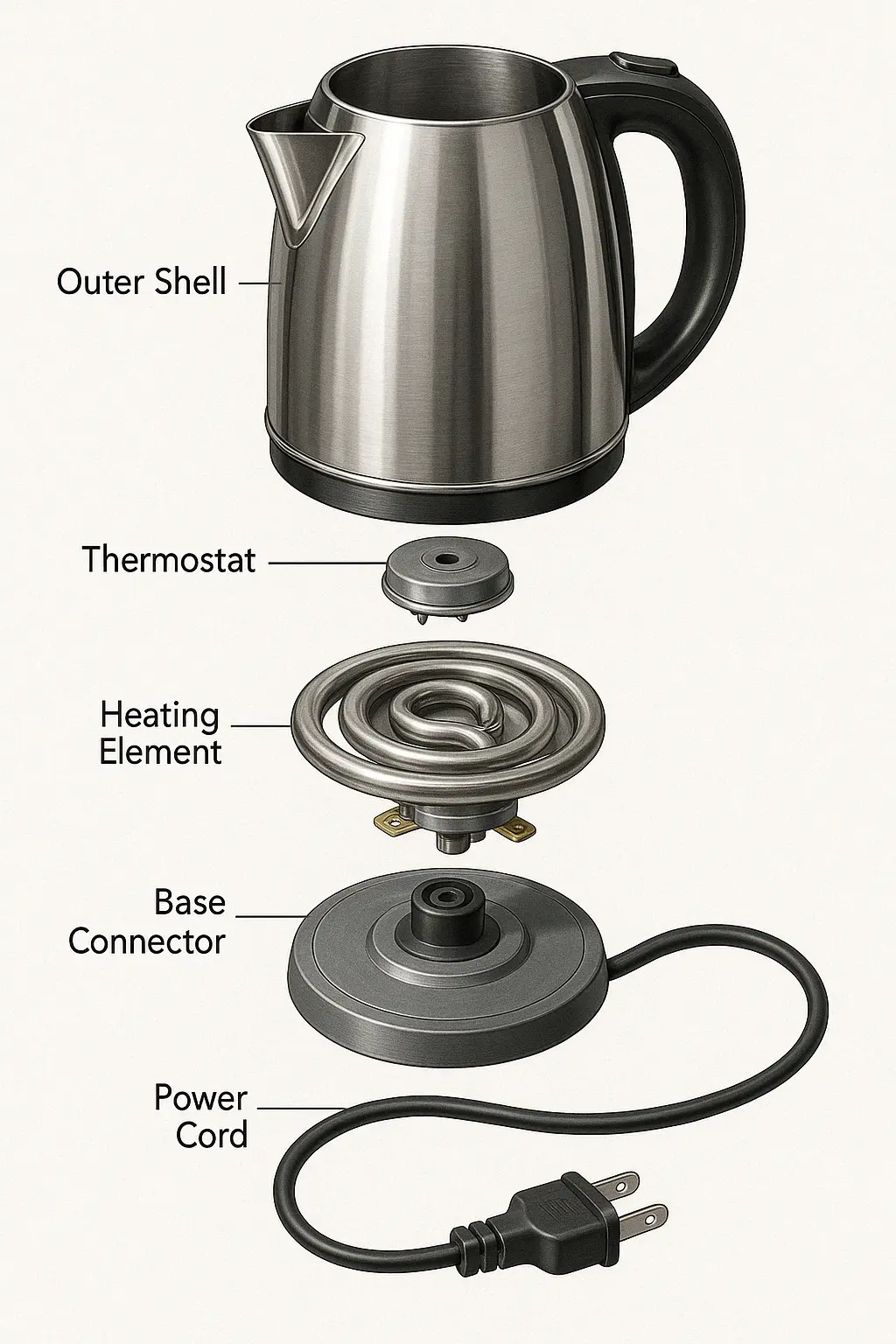

Electric Kettle Amazon Canada Compliance Certifica

Electric Kettle Amazon Canada Compliance Certifica

Do You Understand Amazon Compliance Certification?

Do You Understand Amazon Compliance Certification?

Leave us a message

24-hour online customer service at any time to respond, so that you worry!