What is Wireless EMC Testing?

Electromagnetic Compatibility (EMC) refers to the ability of technical equipment to function without causing interference to other devices or being interfered with by electrical or electromagnetic effects.

In EMC testing, the primary focus is on evaluating a device's immunity to interference and its emission of interference. EMC testing is essential for the market introduction of technical equipment, as international legislators, manufacturers, and distributors establish diverse limits for both interference immunity and emission.

EMC Testing for Wireless Technology Products

In addition to regulatory wireless testing for products employing wireless technologies, EMC testing is required to ensure compliance with international standards, enabling these products to be sold in target markets.

This involves various specifications and limits applicable under different regulatory approval systems. We conduct various accredited EMC tests on wireless technology products, providing all necessary services for market approval from a single source. Among others, these include tests in accordance with:

- Radio Equipment Directive (RED)

- FCC

- ISED

- ETSI EN 301 489 series (specific standards include EN 301 489-1, -2, -3, -7, -9, -17, -19, -24, -25, -27, -33, -50, -51, -52)

- FCC Rule Part 15B

- RSS-GEN & ICES-003

When is EMC Testing Required?

EMC testing is crucial for ensuring a product’s interference-free, safe, and reliable operation while complying with legal regulations.

What Products Require EMC Testing?

All technical equipment from the following fields:

- Industrial engineering

- Consumer electronics

- Automotive engineering

- Aerospace

- Military technology

- Medical technology

- Information technology

EMC Testing for Electrical Equipment

Legislators have made compliance with basic EMC requirements mandatory under the Electromagnetic Compatibility Act (EMVG), aligned with EU Directive 2014/30/EU. For manufacturers, successful EMC testing under this directive represents a key quality feature of their products, preventing failures caused by electromagnetic interference (EMI).

We test electrical equipment according to various EMC standards based on our certifications, including:

- EMC Testing for Household Appliances: Standards EN 55014-1/-2 and EN 60730 form the basis for testing household appliances such as toasters, hairdryers, food processors, microwaves, power tools, vacuum cleaners, heating ovens, slot machines, toy trains, air conditioners, etc.

- EMC Testing for Lighting Equipment: We have developed expertise in EMC testing for lighting equipment, including halogen spotlights, LED lighting, light chains, energy-saving lamps, and neon lights, tested under EN 55015 or EN 61547.

- EMC Testing for Professional Audio-Visual Equipment: Testing the electromagnetic compatibility of cameras, microphones, audio-video monitors, mixing consoles, video walls, etc., is essential for risk-free operation in studios or large display setups. These products are tested in our laboratory according to EN 55103-1/-2.

- EMC Testing for Alarm Systems and Components: Devices such as smoke detectors, alarm systems, light curtains, or sensors are tested according to EN 50130-4.

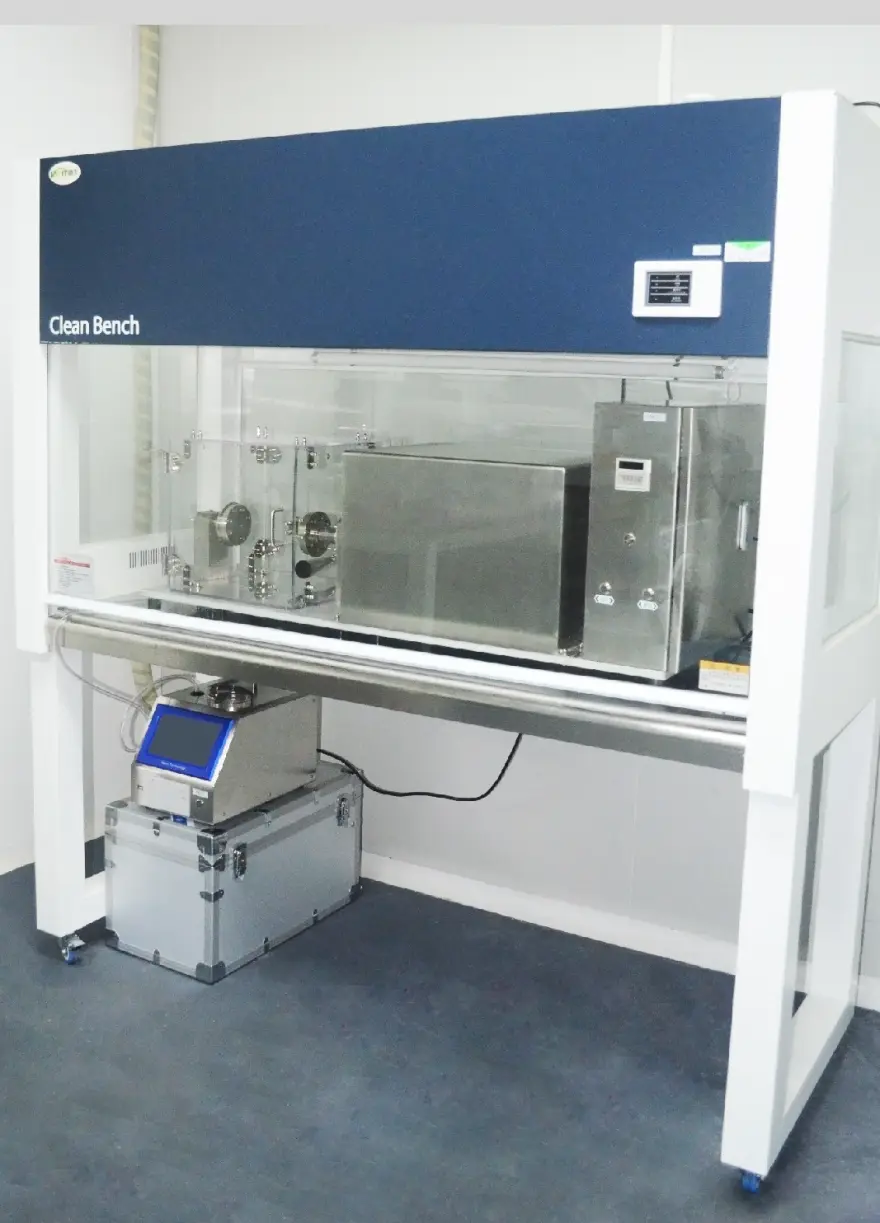

- EMC Testing for Measuring and Laboratory Equipment: Products like centrifuges, sensors, scales, robots, measuring sensors, or similar instruments are tested under EN 61326-1 in our EMC laboratory.

Electromagnetic compatibility testing is especially critical and mandatory for electrically operated medical equipment. The strict regulations on electromagnetic interference in medical environments require reliable test results to eliminate interference.

We provide EMC testing services for electrical medical equipment under the Medical Devices Directive (93/42/EEC / 2007/42/EC) and IEC 60601-1-2, 4th edition.

EMC Testing for Railway Technology Equipment

Our EMC laboratory conducts emission and immunity testing for railway-related equipment, including ticket machines, track and interlocking electronics, alarm systems, vehicle control electronics, and sensors, based on the EN 50121-x and EN 50155 series standards.

Email:hello@jjrlab.com

Write your message here and send it to us

Packaging Validation ISO 11607 Test Report

Packaging Validation ISO 11607 Test Report

What is the ISO 11607-1 Packaging Validation Test?

What is the ISO 11607-1 Packaging Validation Test?

How to get an ISO 11737-1 Test Report?

How to get an ISO 11737-1 Test Report?

Orthopedic Implant Cleanliness Testing

Orthopedic Implant Cleanliness Testing

What is ISO 10993-23:2021 Irritation Testing?

What is ISO 10993-23:2021 Irritation Testing?

ISO 10993-23 Irritation Testing Laboratory

ISO 10993-23 Irritation Testing Laboratory

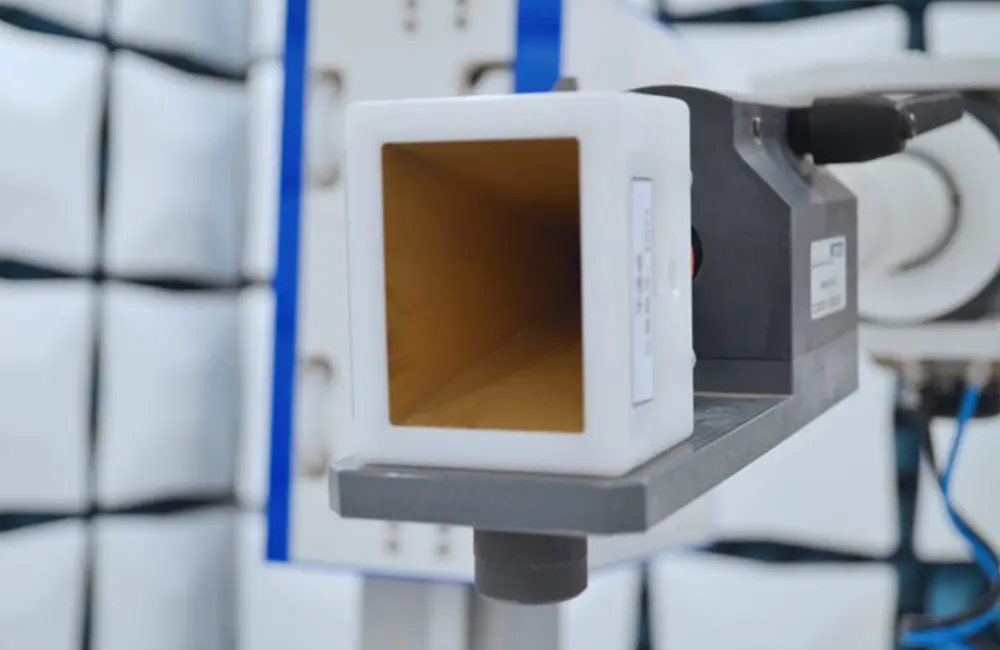

EMI Emissions Testing

EMI Emissions Testing

EMC Standards for Medical Devices

EMC Standards for Medical Devices

Leave us a message

24-hour online customer service at any time to respond, so that you worry!