What is IEC 62133 Certification?

In December 2012, the International Electrotechnical Commission (IEC) officially released the second version of the international safety standard iec 62133:2012 (ed2.0) for battery products. This standard mainly addresses the safety requirements for secondary cells and batteries containing alkaline or non-acidic electrolytes and for portable sealed secondary cells and batteries (including lithium batteries, nickel-metal hydride batteries, and nickel-cadmium batteries). IEC 62133 is the most important standard for exporting lithium-ion batteries, including those used in ITe, tools, laboratory, household, and medical equipment.

According to the IECEE AAG resolution (AAG/563/DSH), from April 15, 2008, onwards, general secondary or portable rechargeable batteries composed of alkaline or non-acidic electrolytes, such as lithium batteries and alkaline batteries, must meet the requirements defined by the battery standard IEC 62133, in addition to complying with the relevant product's finished product standard requirements. This means that for CB verification of rechargeable batteries, both IEC 60950 and IEC 62133 standards must be met.

iec 62133 testing Items

In fact, the testing items for EN 62133 and IEC 62133 are the same, but EN is the European standard while IEC is the international standard.

1. Continuous low-rate charging

2. Vibration test

3. High-temperature impact test

4. Temperature cycling test

5. Short circuit test

6. Free fall

7. Mechanical vibration (acceleration impact)

8. Thermal shock test

9. Compression test

10. High-altitude low-pressure test

11. Overcharge test

12. Forced discharge

13. Abnormal charging test

IEC 62133 Standard Mainly Includes the Following Testing and Verification Items:

Cells: Continuous low-rate charging, vibration, temperature cycling, external short circuit, free fall, impact (collision), thermal misuse (thermal shock), compression, low pressure, overcharge, forced discharge, high-rate charging protection function (lithium systems), marking and packaging, incorrect installation (nickel systems).

Battery: Vibration, shell stress at high temperature, temperature cycling, external short circuit, free fall, impact (collision), marking and packaging, overcharge (nickel systems).

Among these testing and verification items, most are common and routine test items, but some items are worth noting and paying attention to:

1. 13KN Compression: This item tests the cell. Although it is a common and routine item, it explicitly requires compression along the long and short axes for prismatic cells, meaning the cell's length and width planes. According to test experience, polymer soft pack cells often fail with burning or explosion when compressed along the width axis (side). Therefore, it is recommended to pay special attention to this item for polymer soft pack cells.

2. Continuous Low-Rate Charging: This item tests the cell. The standard specifies that a fully charged cell should be continuously charged for 28 days according to the manufacturer's charging method. This item is not commonly seen in other safety standards. Given that battery manufacturers' charging methods are generally constant current and constant voltage charging, manufacturers need to consider and restrict the charging current and the cut-off voltage at full charge comprehensively. It may be necessary to consider the continuous charging capability in the cell's design.

Differences Between EN 62133 and IEC 62133:

1. EN 62133 is a European standard, while IEC 62133 is an international standard.

2. The aim of IEC 62133 is to promote standardization and international cooperation in electrical and electronic engineering, enhancing mutual understanding internationally. EN 62133 aims to coordinate the standards issued by European national standard institutions and eliminate technical trade barriers.

3. IEC 62133 is one of the earliest established international electrotechnical standardization organizations, responsible for the chemical plant in the electrical and electronic engineering fields. EN 62133 was established in 1976 in Brussels, Belgium, formed by the merger of two earlier organizations.

Despite these differences, the procedures and testing items for EN 62133 and IEC 62133 are the same.

EN 62133 and IEC 62133 Processing Procedures:

1. Application: Fill in the application form, provide battery specifications, and a list of safety components.

2. Quotation: Based on the product information, a quotation, timeline, and sample requirements are provided.

3. Applicant Confirms Application: Sign a formal contract, send samples via courier, and arrange payment.

4. Sample Receipt: The laboratory arranges the tests upon receiving the samples.

5. Test Completion: A report is issued upon passing the test, completing the project.

Email:hello@jjrlab.com

Write your message here and send it to us

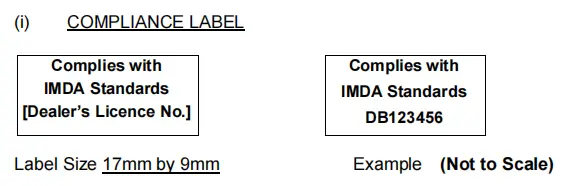

Wireless Certification in Singapore: IMDA Certific

Wireless Certification in Singapore: IMDA Certific

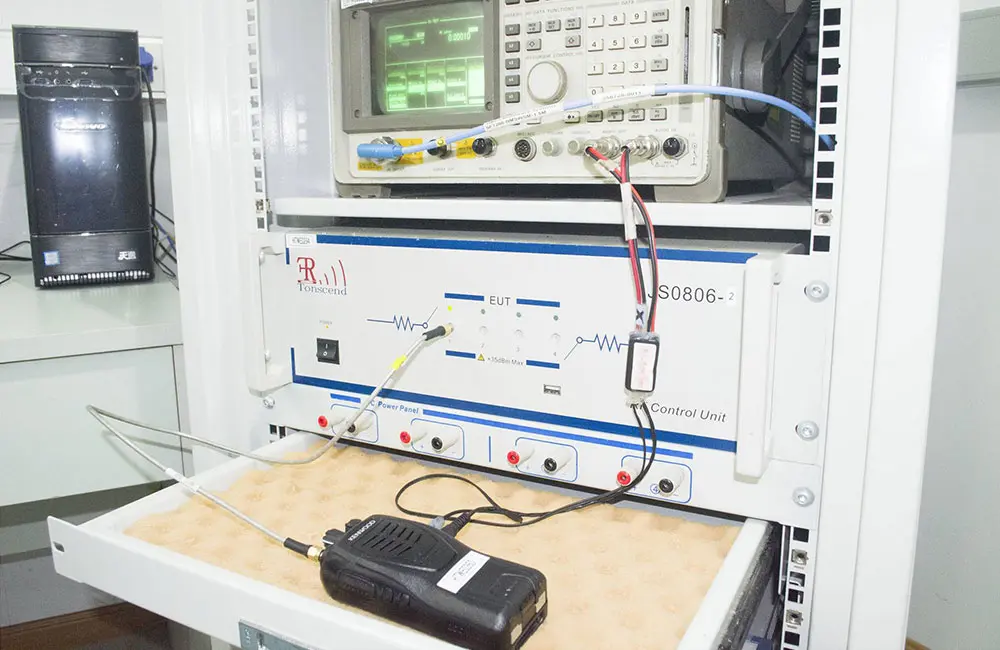

How to get a Singapore IMDA Certificate?

How to get a Singapore IMDA Certificate?

Baby Bath Tub Testing Fees: EN 17072:2018, RoHS &a

Baby Bath Tub Testing Fees: EN 17072:2018, RoHS &a

How Much Does a Glass FCM Test Report Cost?

How Much Does a Glass FCM Test Report Cost?

How Much Does a Silicone FCM Test Report Cost?

How Much Does a Silicone FCM Test Report Cost?

FCM Test Report Cost for Food Storage Containers

FCM Test Report Cost for Food Storage Containers

How Much Does an EN1186 Test Report Cost?

How Much Does an EN1186 Test Report Cost?

Sunglasses AS/NZS 1067 and ISO 12312-1 Testing

Sunglasses AS/NZS 1067 and ISO 12312-1 Testing

Leave us a message

24-hour online customer service at any time to respond, so that you worry!