What is CPSC Certification?

The toy industry, often regarded as the "evergreen tree" of foreign trade, has always held a significant position in global markets. However, children, being a vulnerable and sensitive group, lack the ability to recognize safety risks. Defective children's toys can pose fatal hazards. As a result, various countries have stringent regulations on this popular product category, and exported products must pass CPSC Certification. So, what exactly is CPSC certification? This article introduces CPSC certification, its importance to product safety, and how companies can obtain and maintain this certification.

What is CPSC?

CPSC, the Consumer Product Safety Commission, was established in 1975 in the United States. Its mission is to protect consumers from harm caused by unsafe products. As an independent federal agency, CPSC has the authority to restrict or recall unsafe products, and businesses must comply with its regulatory requirements.

Importance of the CPSIA Act

The Consumer Product Safety Improvement Act (CPSIA), enacted in 2008, expanded CPSC's regulatory scope over product safety, particularly focusing on the safety of children's products. The act introduced safety standards and third-party testing requirements that businesses must implement to ensure product safety.

Scope and Requirements of CPSC Certification

CPSC certification applies to a wide range of products, primarily targeting consumer products with safety risks. Below are common product categories that fall under the scope of CPSC certification:

3.1 Toys:

- Children's toys, games, models, etc.

3.2 Children's Products:

- Cribs, child seats, strollers, high chairs, etc.

3.3 Infant Supplies:

- Bottles, pacifiers, diapers, etc.

3.4 Electrical Appliances:

- Household appliances, children's electronic toys, electronic devices, etc.

CPSC Certification Testing Items

4.1 ASTM F963-17 Standard (For Children's Toys):

- **Mechanical and Physical Tests**: Durability, structural strength, tensile tests, etc.

- **Chemical Composition Tests**: Heavy metal content, toxic substance content, etc.

- **Flammability Tests**: Flame retardance, combustibility, etc.

- **Choking and Suffocation Risk Tests**: Small parts tests, magnetic parts tests, etc.

4.2 16 CFR Part 1219 Standard (For Cribs):

- **Structural and Stability Tests**: Tilt and slide tests, rail stability tests, etc.

- **Material and Construction Tests**: Safety evaluation of crib materials and construction.

- **Mattress Support Tests**: Mattress support capacity and stability tests.

4.3 16 CFR Part 1227 Standard (For High Chairs):

- **Structural and Stability Tests**: Tilt and slide tests, fixture tests, etc.

- **Harness and Footrest Tests**: Reliability of safety harness, stability of footrests, etc.

- **Folding Mechanism Tests**: Strength and reliability of folding mechanisms.

4.4 16 CFR Part 1500 Standard (For Cosmetics and Personal Care Products):

- **Chemical Composition Tests**: Heavy metal content, harmful substance levels, allergenicity tests, etc.

- **Microbial Contamination Tests**: Detection of bacteria, mold, and other microbial contaminants.

- **Labeling and Packaging Requirements**: Proper product labeling and warning language.

4.5 16 CFR Part 1501 Standard (For Children's Fire-Resistant Sleepwear):

- **Flammability Tests**: Burn rate, performance during exposure to heat sources, etc.

- **Labeling and Warning Requirements**: Proper labeling and warning language for sleepwear.

4.6 16 CFR Part 1500.48 Standard (For Toy Small Parts):

- **Small Parts Tests**: Ensures toys meet choking hazard standards for small parts.

4.7 16 CFR Part 1610 Standard (For Textiles):

- **Flammability Tests**: Tests the burn rate of textiles during combustion.

4.8 16 CFR Part 1632 Standard (For Bedding):

- **Mattress Flammability Tests**: Evaluates burn rate and heat release of mattresses.

4.9 16 CFR Part 1700 Standard (For Drug Packaging):

- **Child-Resistant Packaging Tests**: Evaluates whether packaging effectively prevents child access.

How to Obtain CPSC Certification

Obtaining CPSC certification requires companies to provide detailed product technical documentation and undergo safety testing to ensure compliance with CPSC safety standards and requirements. The following steps are typically required:

5.1 Technical Documentation:

Companies need to submit detailed product design and manufacturing information, including material composition, construction drawings, and production processes. This information helps CPSC assess product safety.

5.2 Safety Testing:

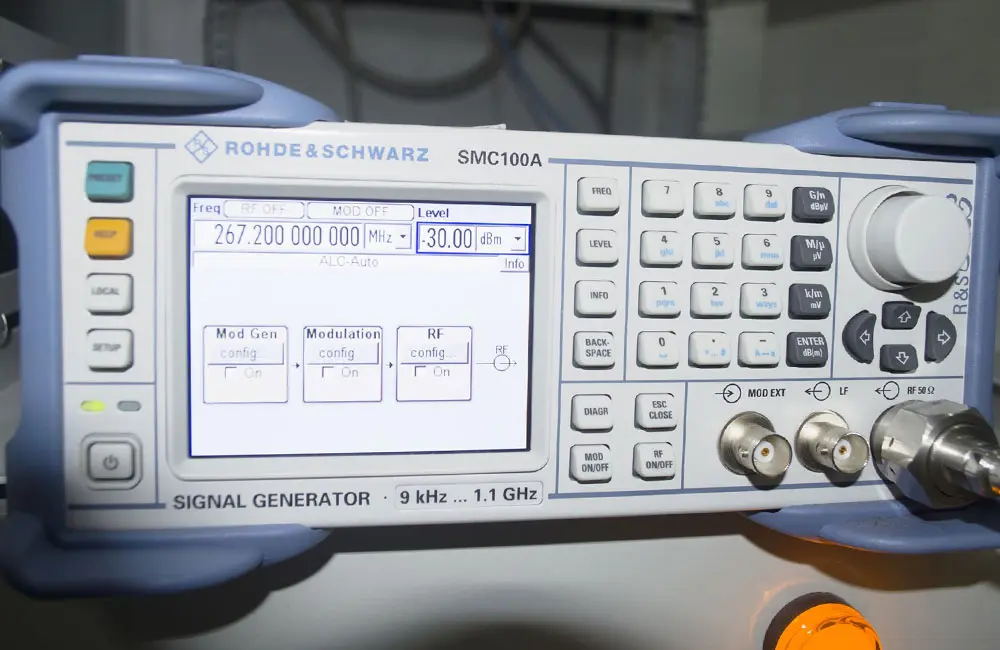

Products must undergo a series of safety tests to evaluate compliance with CPSC safety standards. These include toxicological performance tests, flammability tests, mechanical performance tests, etc. Testing is typically conducted by CPSC-recognized laboratories (e.g., JJR Laboratory in China) with corresponding test reports.

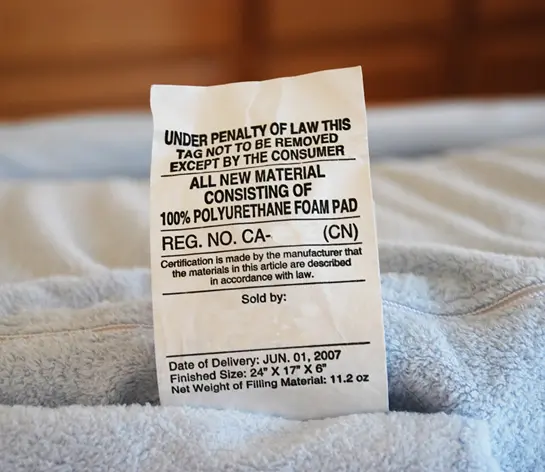

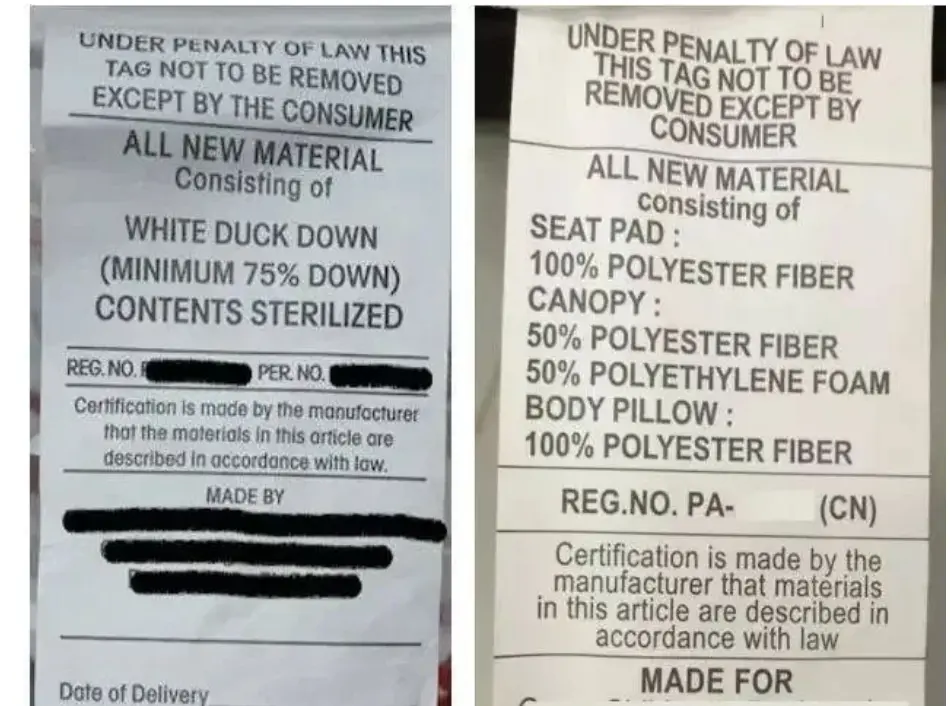

5.3 Labeling and Documentation Requirements:

After obtaining certification, products must bear the CPSC certification mark to indicate compliance with safety standards. Technical documentation and safety instructions must include a copy of the certification for verification.

5.4 Product Modifications and Re-Certification:

Any changes affecting product safety, such as design, material composition, manufacturing processes, or other key aspects, require re-certification.

5.5 Safety Performance Management:

To maintain certification, companies must rigorously control and manage product safety performance through material selection, supply chain management, internal quality control systems, and regular product testing.

5.6 Compliance with Regulations and Standards:

Companies must adhere to relevant regulations and standards, including CPSC safety standards, regulatory requirements, and technical guidelines.

Required Documents for CPSC Certification:

1. Application form

2. Product information (including images, drawings, and specifications)

3. Test samples

CPSC certification costs:

CPSC certification costs vary depending on product complexity. Products with more material types generally incur higher testing fees, typically ranging from $500 to $1,200 at JJR Laboratory in China.

CPSC certification Timeframe:

For standard products, CPSC certification usually takes 5–7 business days (expedited service available), depending on product complexity.

CPSC certification Validity:

CPSC certification remains valid as long as product design and regulatory requirements remain unchanged, unless otherwise specified by buyers.

CPSC certification is crucial for ensuring product safety and building market trust. Companies should strictly follow relevant standards and regulations, investing in product safety control and management to successfully obtain and maintain CPSC certification. For further information, consult JJR Laboratory engineers or refer to related standards and the CPSC official website.

References:

1. [CPSC Official Website](https://www.cpsc.gov/)

2. [ASTM Standards](https://www.astm.org/)

3. [ANSI Standards](https://www.ansi.org/)

4. [NIST Certification and Testing](https://www.nist.gov/)

Email:hello@jjrlab.com

Write your message here and send it to us

High Chair for Children ASTM F404-21 CPC Certifica

High Chair for Children ASTM F404-21 CPC Certifica

U.S. Law Label (URN Number) Registration Q\&A

U.S. Law Label (URN Number) Registration Q\&A

U.S. Furniture Export URN Law Label Registration

U.S. Furniture Export URN Law Label Registration

What is U.S. Law Label Registration?

What is U.S. Law Label Registration?

Rail Transit EN55015/EN50121-4

Rail Transit EN55015/EN50121-4

IEC 60601-1-2 EMC Test for Medical Electrical Equ

IEC 60601-1-2 EMC Test for Medical Electrical Equ

What Are the Safety Tests for Lithium Batteries?

What Are the Safety Tests for Lithium Batteries?

What is the YY 9706.111-2021 Standard?

What is the YY 9706.111-2021 Standard?

Leave us a message

24-hour online customer service at any time to respond, so that you worry!