What is ASTM F2413 Certification Testing Standard?

In today's society, with growing consumer concern about product safety, the astm f2413-18 safety standard has become an important benchmark for assessing the safety performance of footwear products. This article will explore the ASTM F2413-18 safety standard and its application in footwear quality control and production monitoring.

Overview of ASTM F2413-18

ASTM F2413-18 is a standard established by the American Society for Testing and Materials (ASTM), specifying the minimum performance requirements for safety shoes used in various industrial and occupational environments. The standard covers a range of safety features, including:

- Impact resistance

- Compression resistance

- Metatarsal protection

- Puncture resistance

- Electrical hazard protection

- Slip resistance

- Outsole durability

These features ensure that safety shoes provide adequate protection for workers' feet who may be exposed to potential hazards in the workplace.

ASTM F2413-18 is an updated version of the previous ASTM F2413-11 standard and sets higher demands for footwear quality control. It is widely recognized and accepted by regulatory agencies, employers, and safety professionals as a benchmark for evaluating the quality and safety of safety footwear. Manufacturers, distributors, and end users should comply with ASTM F2413-18 to ensure their products meet strict safety requirements.

Safety Footwear Regulations

Regulatory agencies enforce safety footwear regulations to ensure that workers in the workplace are adequately protected from potential foot injuries. These regulations guide manufacturers in designing and producing safety footwear and are developed by regulatory bodies or industry organizations. Compliance with safety footwear regulations is not only a legal requirement but also critical for worker welfare.

ASTM F2413-18 Safety Toe Requirements

One of the key components of ASTM F2413-18 is the safety toe requirement. Safety toes are designed to protect the toes from impact and compression injuries. The ASTM F2413 standard categorizes safety toes into three main types:

1. Steel Toe (ST)

Made of steel, providing excellent protection against impact and compression risks, with durability and weight-bearing capacity.

2. Composite Toe (CT)

Made from non-metallic materials such as plastic, carbon fiber, or Kevlar, lightweight and non-conductive, making it ideal for electrically sensitive environments, while offering protection similar to steel toes.

3. Aluminum Toe (AT)

Made of aluminum, lightweight, and capable of preventing impact and compression risks. It is an ideal choice for workers who need to wear shoes for extended periods.

Safety toes must meet specific performance requirements as defined by ASTM F2413, including the ability to withstand a certain amount of impact energy and compression loads without crushing or puncturing the toes.

How Enterprises Can Ensure Compliance with ASTM F2413-18 Standards

For businesses, ensuring that footwear products comply with ASTM F2413-18 safety standards is a challenging task. Companies need to implement strict quality control and production monitoring measures throughout the manufacturing process:

1. Raw Material Quality Control

When sourcing raw materials, businesses should rigorously test and control the chemical composition, physical properties, and other factors to ensure they meet the standard's requirements.

2. Production Process Monitoring

Effective production monitoring should be implemented to inspect each production stage, ensuring that footwear products meet the standard's specifications. Random checks on production lines should be carried out regularly to identify and address potential issues in a timely manner.

3. Finished Product Testing

Before products leave the factory, each pair of shoes should undergo comprehensive testing to ensure that the final product meets ASTM F2413-18 standards. Non-compliant products should be reworked or scrapped.

4. Third-Party Testing Agencies

To ensure that products comply with ASTM F2413-18 safety standards, many companies choose to conduct product quality testing through third-party testing agencies (such as China JJR Laboratories). These agencies have professional testing equipment and staff, capable of conducting comprehensive performance tests on footwear products and providing accurate, reliable test reports. Additionally, third-party agencies can offer consulting and training services to help businesses improve product quality and safety performance.

As product safety requirements increase, the significance of the ASTM F2413-18 safety standard in footwear quality control and production is becoming more prominent. Through strict quality control, production monitoring, and third-party testing, businesses can ensure their products meet high safety standards and provide consumers with safer and more reliable footwear.

Email:hello@jjrlab.com

Write your message here and send it to us

High Chair for Children ASTM F404-21 CPC Certifica

High Chair for Children ASTM F404-21 CPC Certifica

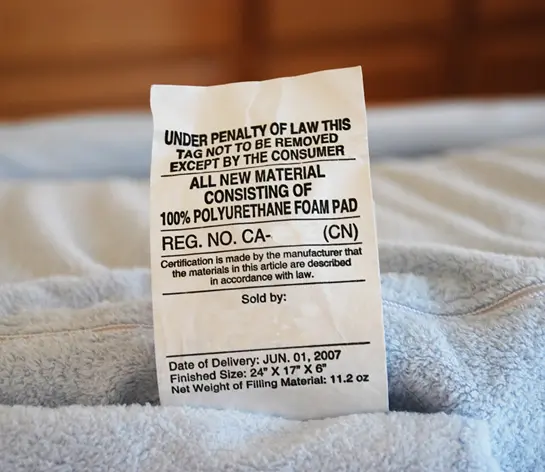

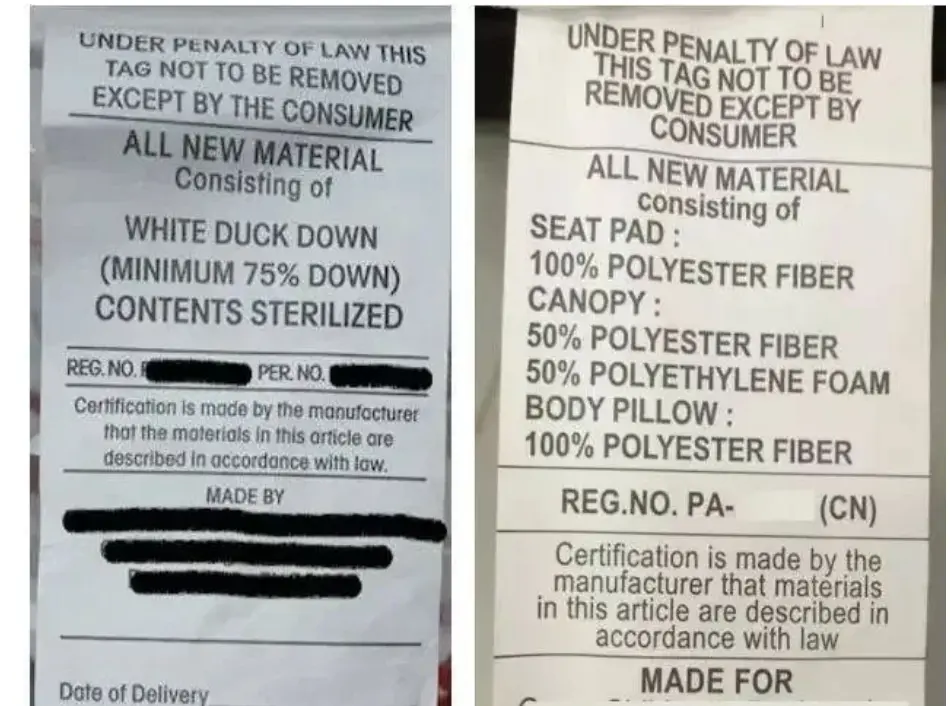

U.S. Law Label (URN Number) Registration Q\&A

U.S. Law Label (URN Number) Registration Q\&A

U.S. Furniture Export URN Law Label Registration

U.S. Furniture Export URN Law Label Registration

What is U.S. Law Label Registration?

What is U.S. Law Label Registration?

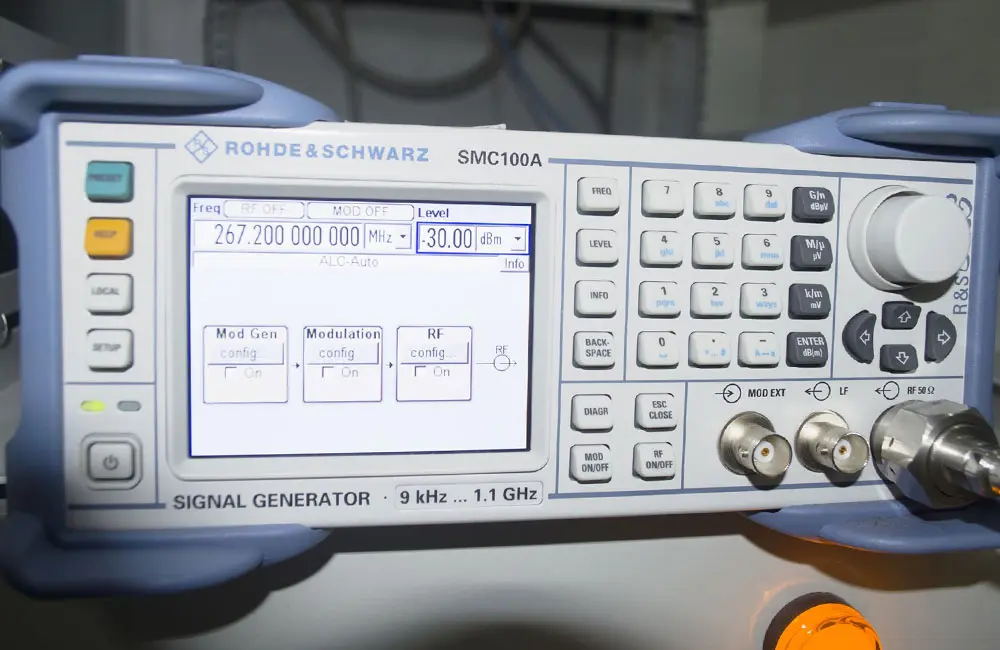

Rail Transit EN55015/EN50121-4

Rail Transit EN55015/EN50121-4

IEC 60601-1-2 EMC Test for Medical Electrical Equ

IEC 60601-1-2 EMC Test for Medical Electrical Equ

What Are the Safety Tests for Lithium Batteries?

What Are the Safety Tests for Lithium Batteries?

What is the YY 9706.111-2021 Standard?

What is the YY 9706.111-2021 Standard?

Leave us a message

24-hour online customer service at any time to respond, so that you worry!