What is an ESD test? How to obtain it?

What is ESD?

ESD stands for Electrostatic Discharge, which refers to the sudden flow of electricity between two objects with different electrical potentials. This occurs when static electricity accumulates on an object and then comes into contact with another object that has a different electrical potential.

ESD can be generated from various sources, such as friction, air movement, or contact with other objects. It is common in everyday life and can cause damage to electronic components, especially those sensitive to electrostatic discharge.

ESD can range from a barely noticeable minor shock to a more severe discharge that may cause permanent damage to electronic devices. This is particularly problematic in environments where electronic components are manufactured, handled, or transported.

Various measures are taken to prevent damage from ESD, such as using anti-static mats, wristbands, and other protective equipment. ESD Tests are also conducted to assess an electronic device's ability to withstand and dissipate electrostatic discharge.

What is an ESD test?

An ESD test, also known as Electrostatic Discharge testing, is a procedure used to evaluate an electronic device's ability to withstand and dissipate electrostatic discharge. This test typically involves subjecting the device to high-voltage discharges through contact or air discharge and measuring the resulting current and voltage. The device is then evaluated based on whether it continues to function normally after the discharge. ESD testing is crucial during the product development process of electronic devices, especially those sensitive to electrostatic discharge, to ensure they can withstand various static events that may occur in real-world scenarios and meet regulatory safety and performance requirements.

There are various industry standards for ESD testing, including IEC 61000-4-2 from the International Electrotechnical Commission and ANSI S20.20 from the American National Standards Institute.

ESD Test Methods

Depending on the type of equipment being tested and the industry standards followed, different ESD test methods are available. Below are some commonly used ESD test methods:

- Human Body Model (HBM) Testing: This method involves releasing high-voltage pulses through a human body simulator to simulate the electrostatic discharge that may occur when a person touches an electronic device. HBM testing is commonly used to test the sensitivity of electronic devices to electrostatic discharge.

- Machine Model (MM) Testing: This method involves releasing high-voltage pulses through a machine model simulator to simulate the electrostatic discharge that may occur when electronic devices come into contact with manufacturing equipment. MM testing is typically used to test the robustness of electronic devices against electrostatic discharge.

- Charged Device Model (CDM) Testing: This method involves releasing high-voltage pulses through a charged device, such as an IC package, to simulate the electrostatic discharge that may occur during the handling or assembly of the device. CDM testing is often used to test the sensitivity of electronic devices to electrostatic discharge.

- IEC 61000-4-2 Testing: This method involves releasing high-voltage pulses through a probe to simulate the electrostatic discharge that may occur when electronic devices are exposed to electrostatic discharge events. IEC 61000-4-2 testing is commonly used to test the immunity of electronic devices to electrostatic discharge.

In all ESD test methods, electronic devices are evaluated based on whether they continue to function normally after discharge. The test results are then compared with industry standards to determine whether the device has passed the test.

ESD Test Standards

Several ESD test standards are commonly used in the electronics industry to assess an electronic device's ability to withstand and dissipate electrostatic discharge. Below are some of the most commonly used ESD test standards:

- IEC 61000-4-2: This is a standard published by the International Electrotechnical Commission (IEC) that provides a test method for evaluating the immunity of electronic devices to electrostatic discharge.

- ANSI/ESD S20.20: This is a standard published by the American National Standards Institute (ANSI) that provides requirements for ESD control programs to protect electronic devices from ESD damage during manufacturing, handling, and use.

- ANSI/ESD STM12.1-2019: This is a standard published by ANSI that provides a method for testing the electrostatic discharge (ESD) performance of packaging materials used to protect electronic devices during handling, transportation, and storage.

- MIL-STD-883: This is a standard published by the United States Department of Defense that provides test methods for evaluating the performance and reliability of electronic devices in military applications, including ESD testing.

- JEDEC JESD22-A114: This is a standard published by the Joint Electron Device Engineering Council (JEDEC) that provides a test method for evaluating the robustness of integrated circuits to human body model (HBM) electrostatic discharge events.

- JEDEC JESD22-C101: This is a standard published by JEDEC that provides a test method for evaluating the robustness of integrated circuits to machine model (MM) electrostatic discharge events.

- GB/T 19951-2019: This is a Chinese national standard that provides a method for testing the electrostatic discharge (ESD) performance of electronic devices. The standard outlines the test procedures, equipment requirements, and performance criteria for ESD testing.

- ISO 10605-2008: This is an international standard that provides a method for testing the electrostatic discharge (ESD) immunity of electronic devices. The standard, published by the International Organization for Standardization (ISO), is widely accepted in the electronics industry.

These ESD test standards provide guidelines and procedures for conducting ESD tests and evaluating the performance of electronic devices under ESD conditions. Compliance with these standards is often required by regulatory bodies and customers to ensure that electronic devices are reliable and safe to use.

ESD Test Standard IEC 61000-4-2

IEC 61000-4-2 is a standard published by the International Electrotechnical Commission (IEC) that provides a test method for evaluating the immunity of electronic devices to electrostatic discharge (ESD).

IEC 61000-4-2 outlines the test procedures, test equipment, and performance standards for ESD testing.

The IEC 61000-4-2 standard applies to all types of electronic devices, including consumer electronics, industrial equipment, and medical devices. The standard specifies several test levels, ranging from 2 kV to 15 kV, to simulate different ESD events that may occur during the handling, transportation, and use of electronic devices.

During testing, an ESD generator is used to discharge high-voltage pulses onto the electronic device being tested. The performance or functionality of the device is then evaluated to determine if there are any changes. The test results are then compared with the performance standards specified in the standard to determine whether the device has passed the test.

Compliance with the IEC 61000-4-2 standard is often required by regulatory bodies, industry organizations, and customers to ensure that electronic devices are reliable and safe to use in various environments. The standard provides a widely accepted method for testing the immunity of electronic devices to ESD events, which is crucial for preventing damage and ensuring the long-term performance of electronic devices.

ESD Test Standard ANSI/ESD S20.20

ANSI/ESD S20.20 is a standard published by the American National Standards Institute (ANSI) that provides requirements for electrostatic discharge (ESD) control programs to protect electronic devices from ESD damage during manufacturing, handling, and use. The standard outlines guidelines for establishing an ESD control program, which includes the following:

- ESD Protected Area (EPA): A defined space where all ESD-sensitive items are handled, manufactured, and inspected.

- Grounding: All conductive materials within the EPA must be grounded, including floors, work surfaces, chairs, and personnel.

- Personnel Grounding: All personnel within the EPA must be grounded using wrist straps or other approved grounding devices.

- ESD Protective Packaging: All ESD-sensitive items must be packaged with ESD protective materials, such as static shielding bags or conductive boxes.

- ESD Control Procedures: Procedures must be established and followed to ensure that all activities within the EPA are conducted in a manner that minimizes the risk of ESD damage.

The ANSI/ESD S20.20 standard serves as a comprehensive framework for ESD control programs and is widely accepted and recognized in the electronics industry. Compliance with this standard is often required by regulatory bodies and customers to ensure that electronic devices are reliable and safe to use.

The ANSI/ESD S20.20 standard provides a consistent and reliable approach to ESD control, which is crucial for preventing damage to electronic devices and ensuring their long-term performance.

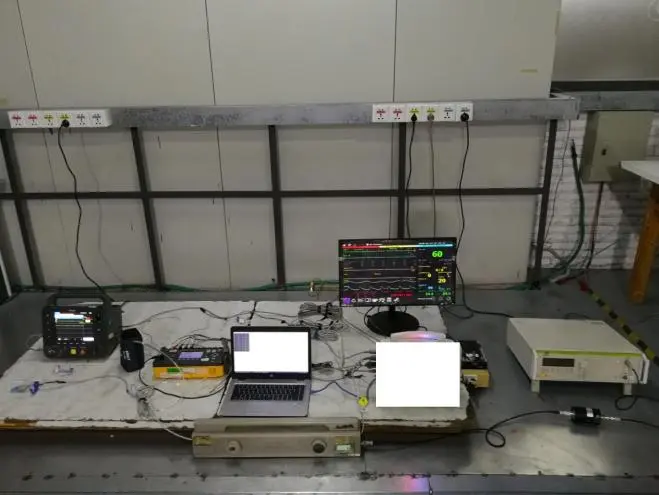

ESD Testing Equipment

ESD testing equipment is specialized equipment used to generate and measure electrostatic discharge during ESD testing. Below are some examples of ESD testing equipment:

- ESD Guns: These are handheld devices that generate electrostatic discharge pulses to simulate ESD events that may occur during the handling and use of electronic devices.

- Electrostatic Discharge Simulators: These are benchtop devices that generate electrostatic discharge pulses to simulate ESD events that may occur during the handling and use of electronic devices.

- Human Body Model and Machine Model Simulators: These are specialized simulators used to generate HBM and MM pulses for ESD testing.

- Charge Plate Monitors: These devices are used to measure static charges on surfaces such as floors or workstations to ensure they are properly grounded.

- ESD Testers: These devices combine multiple ESD testing functions, such as ESD guns and simulators, into one device.

- ESD Workstations: These are specialized workstations designed to minimize the risk of ESD damage during the handling and assembly of electronic devices.

ESD testing equipment is essential for accurately

simulating and measuring electrostatic discharge during ESD testing to ensure that electronic devices meet regulatory requirements and can withstand real-world ESD events.

China JJR Laboratory will provide a one-stop service for ESD testing, including preliminary evaluation, preparation and submission of relevant materials, full follow-up during the testing process, and report interpretation, data analysis, and rectification recommendations.

Email:hello@jjrlab.com

Write your message here and send it to us

EMC Pre Compliance Testing

EMC Pre Compliance Testing

PAHs Testing (Food and Textile)

PAHs Testing (Food and Textile)

Where to Apply for the EU RoHS Test Report?

Where to Apply for the EU RoHS Test Report?

Children’s Products and Toy Testing

Children’s Products and Toy Testing

What is a GB 31701 Test Report?

What is a GB 31701 Test Report?

UN 38.3 Transportation Test

UN 38.3 Transportation Test

Toxicological Risk Assessment of Medical Devices

Toxicological Risk Assessment of Medical Devices

How to get the Vacuum Cleaner UL 1017 Test Report?

How to get the Vacuum Cleaner UL 1017 Test Report?

Leave us a message

24-hour online customer service at any time to respond, so that you worry!