What Does EMC Stand For?

Electromagnetic Compatibility (EMC) is a crucial aspect of the design and manufacturing of electronic devices. Simply put, EMC refers to the ability of electronic equipment to operate normally in an environment shaRED with other devices, without causing electromagnetic interference (EMI) to those devices, and without being affected by interference from other devices. Every electronic device on the market must meet EMC standards, ensuring compliance with the regULations of the country or region where it is sold.

EMC is important not only for manufacturers but also for end-users, as it ensures that devices function as expected without causing performance issues or safety hazards. Many countries and regions have strict EMC regulations, requiring devices to undergo testing and certification. Below, JJR Laboratory in China will explain what EMC is, how emc testing works, and provide an overview of common EMC regulations and standards worldwide.

What is EMC?

EMC (Electromagnetic Compatibility) refers to the ability of electronic equipment to function without causing electromagnetic interference to other devices and to operate normally when exposed to electromagnetic energy (also known as emission) from other devices. Simply put, EMC ensures that devices can coexist without interfering with each other’s function, performance, or safety.

This is especially important today, as many environments contain numerous devices that can potentially cause electromagnetic interference—ranging from phones and personal computers to office equipment, industrial machinery, security systems, and more.

To ensure emc compliance, many countries and regions require that electronic devices undergo testing before they are sold. These tests ensure that the devices meet specific electromagnetic radiation and immunity standards. In the United States, EMC regulations are set by the Federal Communications Commission (FCC), with most devices being regulated under fcc part 15 rules.

Common EMC-Related Abbreviations

- EMI (Electromagnetic Interference)

- ESD (Electrostatic Discharge)

These terms are often confused with EMC, so let’s explain them in more detail.

EMI vs. EMC

EMI stands for Electromagnetic Interference, which refers to the disturbance caused by one device (Device A) to another device (Device B) in its vicinity. The key difference between EMC and EMI is that while EMI refers to the interference, EMC focuses on the ability of a device to operate without interfering with others.

Products that meet EMC requirements must undergo emi testing during the development process. A device that meets EMC standards should not generate EMI, as it has been proven to have sufficient electromagnetic immunity and low radiation levels to operate seamlessly in its predefined environment.

Examples of EMI:

- EMI on power lines: For instance, when a blender or coffee grinder is used in the kitchen, it may cause the TV to flicker. This occurs because the blender or grinder is emitting interference through the power line that affects the TV.

- Radio Frequency Interference: If you’re listening to music through audio equipment and occasionally hear noise in the speakers, this could be caused by interference from your phone, especially when receiving a text message. The radio frequency signals from the phone can interfere with the audio equipment.

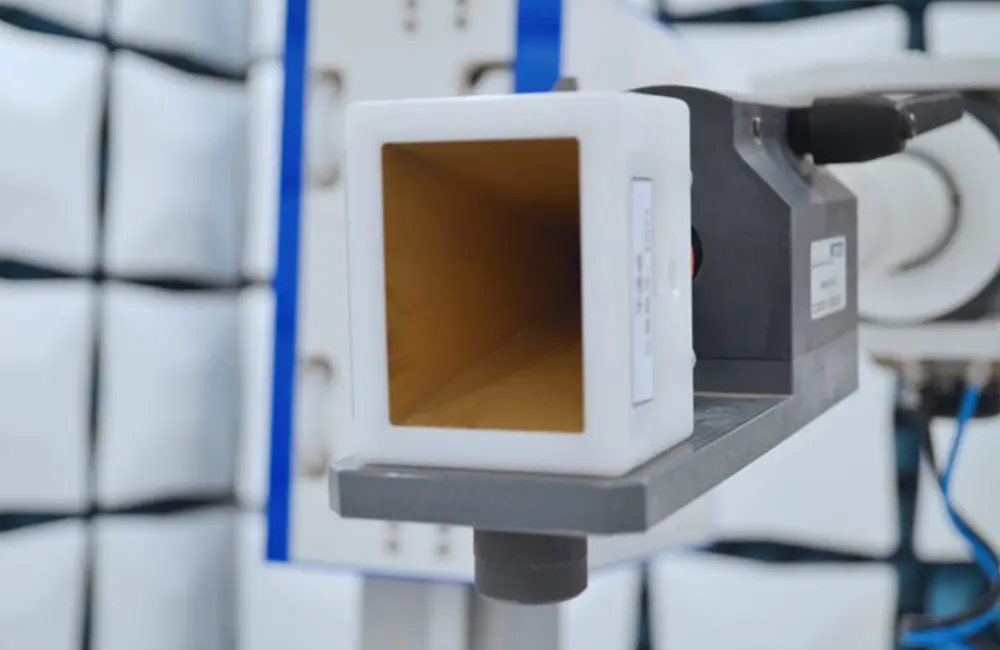

How EMC Testing Works

EMC testing is conducted by accredited Electrical Testing laboratories before the product is released to market. The testing involves two primary types:

1. Radiation Testing: This checks the electromagnetic energy emitted by the device, verifying that it does not exceed regulatory limits that could cause interference.

2. Immunity Testing: This evaluates the device’s ability to operate normally under electromagnetic interference, ensuring it works as intended when used near other electrical and electronic devices.

During the EMC testing process, specialized equipment is used to simulate the electromagnetic environment the device may encounter during normal operation. Various performance and response aspects of the device are observed and measured to ensure it meets the required standards. After testing, a report is prepared to provide written evidence that the device complies with all relevant EMC standards.

Common EMC Standards

1. FCC Part 15

The Federal Communications Commission (FCC) has established Part 15 rules that apply to devices that emit radiofrequency (RF) energy. These rules govern both intentional radiators (devices that are designed to emit RF energy as part of their function) and unintentional radiators.

JJR Laboratory in China provides guidance on FCC Class A and Class B devices, explaining the differences between these devices and how FCC regulations apply to them.

FCC Part 15 establishes limits for radiation and immunity. To comply with Part 15, a device must undergo testing to ensure it operates within the limits set by the FCC.

As an accredited electrical testing laboratory, JJR Laboratory offers fcc part 15 testing services, which are part of the full suite of services it provides to manufacturers.

2. EU EMC Directive

The European Union (EU) has its own set of EMC regulations, known as the EMC Directive. This directive ensures that electrical and electronic devices meet specific radiation and immunity requirements. Electronic devices must comply with the EU EMC Directive before they can be sold within the EU.

3. Radio Equipment Directive (RED)

The Radio Equipment Directive (RED) is another EU standard specifically for radio equipment. It ensures that radio equipment meets certain EMC requirements, as well as health, safety, and other factors.

Contact JJR Laboratory for EMC Testing

If you plan to sell your electronic devices in the United States, EU, or other major markets, completing EMC testing is a crucial step to ensure your products comply with all relevant regulations and gain market access. As an accredited electrical testing laboratory, JJR Laboratory specializes in helping electronic manufacturers obtain the necessary certifications, such as FCC, CE, and other EMC compliance marks.

Email:hello@jjrlab.com

Write your message here and send it to us

How Do You Get a CE Mark

How Do You Get a CE Mark

IEC 60529 IP Rating Ingress Protection Standard

IEC 60529 IP Rating Ingress Protection Standard

IEC 60601-1 Medical Electrical Equipment Basic Saf

IEC 60601-1 Medical Electrical Equipment Basic Saf

European Authorized Representative Medical Devices

European Authorized Representative Medical Devices

EU Waste Electrical and Electronic Equipment Direc

EU Waste Electrical and Electronic Equipment Direc

How to Get CE Approval

How to Get CE Approval

Accelerated Ageing Test

Accelerated Ageing Test

IP Ingress Protection Testing

IP Ingress Protection Testing

Leave us a message

24-hour online customer service at any time to respond, so that you worry!