UN38.3 Battery Safety Test Certification

IATA (International Air Transport Association) has revised its Dangerous Goods Regulations to the 59th edition, effective January 2018. Several changes impact lithium battery air transportation. This article provides a brief analysis of these new rules regarding lithium battery air transport.

Key changes in lithium battery air transport regulations include:

1. Passengers or crew members are allowed to carry up to 15 portable electronic devices and 20 spare batteries. Approval from the airline is required if these limits are exceeded.

2. The old lithium battery handling label has been removed, and a new lithium battery transportation label (Lithium Battery Mark) has been introduced, specifying that the height of the UN code must be no less than 12 mm. The new label is mandatory starting January 1, 2019.

1. un38.3 test report Version Update:

- For fourth and earlier versions of the un38.3 test report, upgrading to the sixth version requires retesting for T5 (external short circuit) and T4 (impact) tests.

- Reports from the fifth edition revision 1 and revision 2 require retesting for the T5 (external short circuit) test to upgrade to the sixth version.

*Note: The current version is the sixth, but fourth and fifth versions of UN38.3 are still valid.*

2. Major Changes in the 59th Edition DGR:

1. PI 965 and PI 968 packaging methods require additional isolation:

- PI 965 and PI 968 IA and IB sections prohibit packaging with explosive materials (except Class 1.4S), flammable gases (Class 2.1), flammable liquids (Class 3), flammable solids (Class 4.1), and oxidizers (Class 5.1). Part II prohibits packaging with any dangerous goods.

- Power banks (PI 965 II) and lithium batteries installed in equipment (PI 967 II) cannot be in the same packaging.

2. The font height of the UN code on the new lithium battery label must be at least 12 mm.

- The new lithium battery label (see Table 1) will be officially implemented on January 1, 2018, and the old label can be used until December 31, 2018.

3. Major Changes in Sea Freight IMDG 38-16 Edition:

1. Lithium battery packaging that complies with special provision SP 188 must be labeled with the lithium battery label (same as for air freight), except in the following two cases:

- The package contains only button cells installed in equipment.

- A shipment (one consignment) contains only two or fewer packages, and each package contains no more than two batteries or four cells.

2. New requirements for unproduced lithium battery sea transport: P910.

UN38.3 Testing Requirements

- T.1 Altitude Simulation Test: Store for over 6 hours at ≤11.6kPa and 20±5°C with no leakage, venting, disassembly, rupture, or fire.

- T.2 Thermal Test: High/low temperature shock test between 72±2°C and -40±2°C, with rapid temperature changes and storage times ≥6h.

- T.3 Vibration Test: Sinusoidal vibration from 7Hz to 200Hz, 3 hours in 3 directions.

- T.4 Shock Test: Half-sine shock at 150g for 6ms or 50g for 11ms, three times per direction.

- T.5 External Short Circuit Test: Short-circuited at 55±2°C with external resistance <0.1Ω.

- T.6 Impact Test: 9.1kg weight dropped from 61±2.5cm onto a 15.8mm rod on the battery.

- T.7 Overcharge Test: Overcharged for 24 hours at twice the maximum continuous charging current and voltage.

- T.8 Forced Discharge Test: Forced discharge using a 12V DC power source.

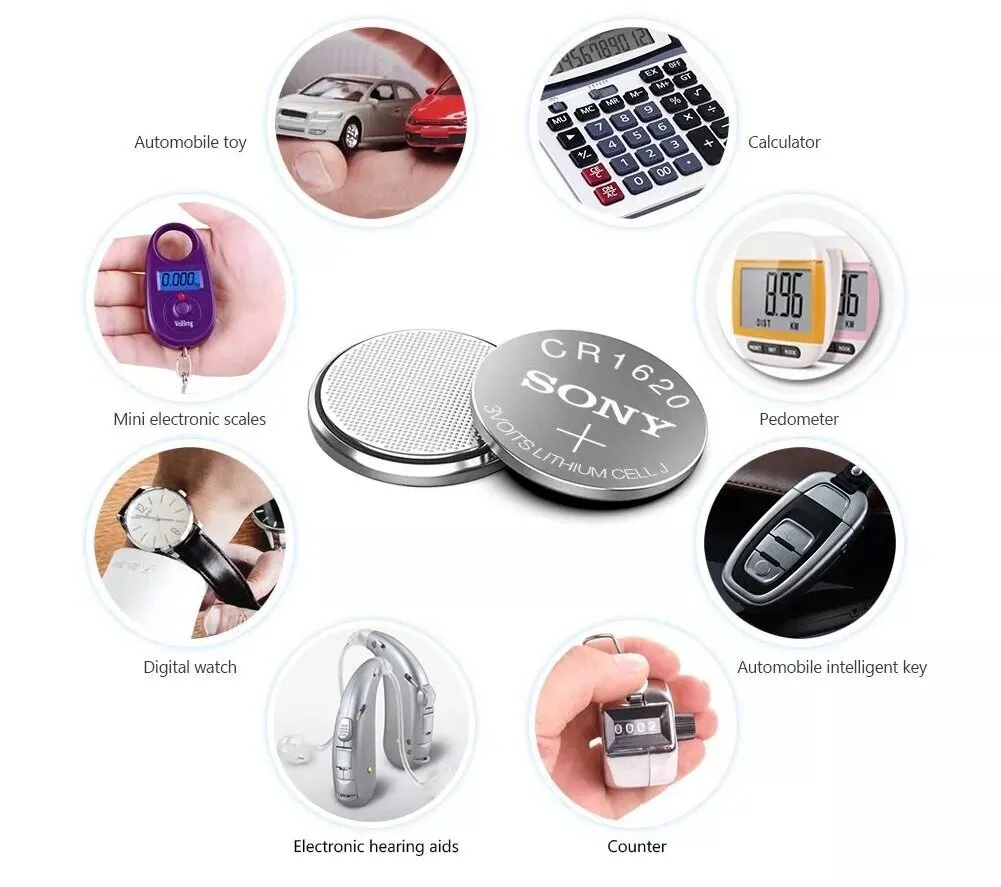

What Products Require UN38.3 Testing:

1. Lead-acid batteries (e.g., automotive batteries).

2. Power batteries (e.g., electric vehicle batteries).

3. Mobile phone batteries (e.g., lithium-ion, NiMH batteries).

4. Small secondary batteries (e.g., laptop batteries, camera batteries).

5. Primary batteries (e.g., alkaline zinc-manganese batteries).

Required Documents for UN38.3 Application:

1. 25 cells and 16 battery packs (samples must include watt-hour markings).

2. Cell and battery specifications.

3. Application form.

4. Power of attorney.

5. Transport statement and documents.

6. ISO9000 certificate for the battery manufacturer.

7. Photos of the packaging, both internal and external, clearly showing labels and markings.

Email:hello@jjrlab.com

Write your message here and send it to us

Packaging Validation ISO 11607 Test Report

Packaging Validation ISO 11607 Test Report

What is the ISO 11607-1 Packaging Validation Test?

What is the ISO 11607-1 Packaging Validation Test?

How to get an ISO 11737-1 Test Report?

How to get an ISO 11737-1 Test Report?

Orthopedic Implant Cleanliness Testing

Orthopedic Implant Cleanliness Testing

What is ISO 10993-23:2021 Irritation Testing?

What is ISO 10993-23:2021 Irritation Testing?

ISO 10993-23 Irritation Testing Laboratory

ISO 10993-23 Irritation Testing Laboratory

EMI Emissions Testing

EMI Emissions Testing

EMC Standards for Medical Devices

EMC Standards for Medical Devices

Leave us a message

24-hour online customer service at any time to respond, so that you worry!