UL4200A-2023 Testing Content and Solutions

1. Applicable products are consumer (household) products installed with lithium button cells with a diameter <32mm, where the diameter is larger than the height (additional requirements may apply in certain terminal product standards).

2. The main purpose of ul4200a testing (but not limited to this) is to REDuce the risk of accidental ingestion by children.

Below is a detailed explanation of ul4200A test items:

3. Structure

3.1 For terminal products with "user-removable or replaceable batteries," the structure must meet the following requirements:

3.1.1 Use probe 11 of IEC 61032 for testing; the battery shoULd not be accessible. During the inspection, if the enclosure can be opened without tools or with fewer than two independent, consecutive actions by hand, the enclosure must be opened for evaluation.

3.1.2 The product must be designed to prevent children from moving the battery by:

- Requiring a tool (such as a screwdriver or coin) to open the battery compartment cover/door, or

- Requiring at least two independent, simultaneous actions by hand to open the battery compartment cover or door.

3.1.3 If the battery compartment cover or door is fastened with screws or similar fasteners, the fasteners must be captive to the cover or door. Captive screws should be used.

3.2 For products with "non-user-removable or non-user-replaceable batteries," the design must effectively prevent users or children from removing the battery. The product must be designed so that:

- 3.2.1 The battery cannot be accessed through the enclosure or similar means, or

- 3.2.2 The battery is completely secured through welding, riveting, or similar methods.

4. Testing Requirements

4.1 Abuse Test:

- Portable products should be dropped 3 times, and handheld products should be dropped 10 times. Each drop should be from a height of 1 meter onto a horizontal hardboard.

- The enclosure or battery compartment cover/door must withstand a 2J impact test, tested 3 times.

- Crush test: A force of 330N is applied to the exposed surface for 10 seconds using a flat surface approximately 100mm x 250mm.

- After tests (a), (b), and (c), apply 45N of force for 10 seconds using probe 11 of IEC 61032. The battery must remain inaccessible. During probing, the battery compartment cover/door should not open, and the product must maintain normal functionality.

4.2 Installation Robustness Test: For "non-user-removable or replaceable batteries," a hook should be used to apply an outward force of 20N for 10 seconds. The battery must not become detached.

Many products containing coin batteries often fail to comply with the battery compartment cover/door design requirements during UL4200A testing. We recommend manufacturers refer to the requirements of section 3.1.3 to improve the design of the battery compartment cover/door by using captive screws for protection.

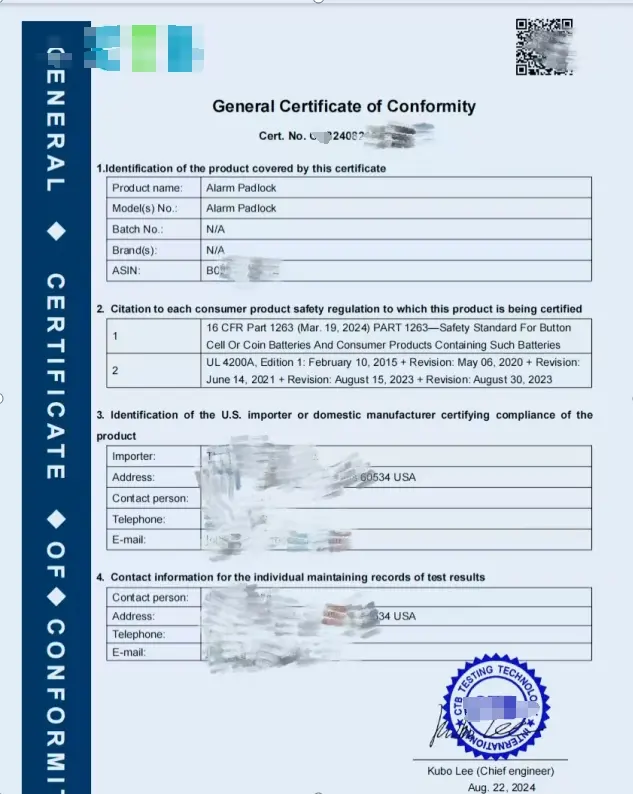

About GCC

The General Certificate of Conformity (GCC) lists compliance with UL 4200a based on a passing test report.

Below is a template for a gcc certificate:

China JJR is an ISO/IEC 17025 authorized laboratory, providing ul 4200a-2023 testing services at a cost of $698. Welcome to consult!

Email:hello@jjrlab.com

Write your message here and send it to us

How Do You Get a CE Mark

How Do You Get a CE Mark

IEC 60529 IP Rating Ingress Protection Standard

IEC 60529 IP Rating Ingress Protection Standard

IEC 60601-1 Medical Electrical Equipment Basic Saf

IEC 60601-1 Medical Electrical Equipment Basic Saf

European Authorized Representative Medical Devices

European Authorized Representative Medical Devices

EU Waste Electrical and Electronic Equipment Direc

EU Waste Electrical and Electronic Equipment Direc

How to Get CE Approval

How to Get CE Approval

Accelerated Ageing Test

Accelerated Ageing Test

IP Ingress Protection Testing

IP Ingress Protection Testing

Leave us a message

24-hour online customer service at any time to respond, so that you worry!