UL 508A Certification Testing for Industrial Control Cabinets

Key considerations for exporting to the North American market

As the slogan of returning manufacturing to the United States grows louder and louder, industrial equipment exports to the United States have reached a new peak.

If your product wants to enter the US market, you need to focus on meeting standards UL 508A and NFPA 79 (the Canadian equivalent standards are CSA C22.2 No. 286 and CSA C22.2 No. 301) .

The above standards clearly require that overcurrent protection devices on the power circuit must comply with UL 489 /CSA C22.2 No.5, and UL 1077 /CSA C22.2 No. 235 cannot be used.

So, what are the specific differences between the two types of overcurrent protection devices, UL 489 and UL 1077? China JJR will give you an in-depth answer to the differences between the two.

How to choose between UL 489 and UL 1077?

In the UL 508A standard :

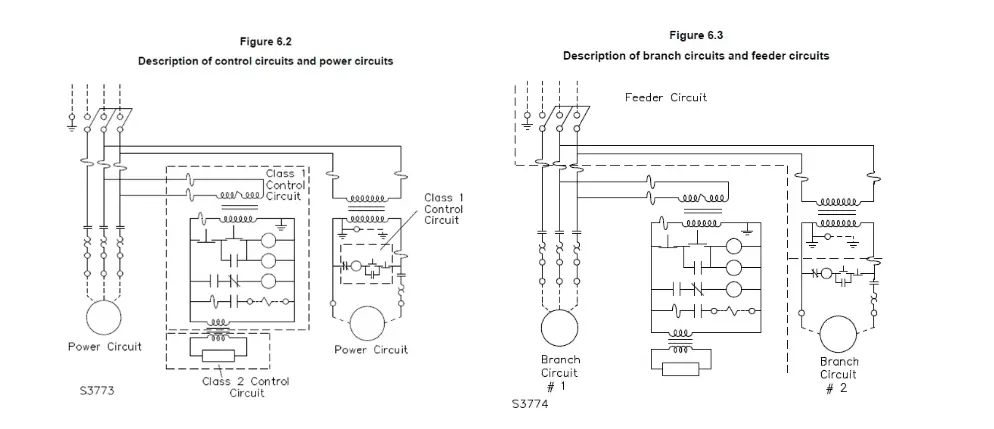

The circuit is divided into: Feeder circuit, Branch circuit, Control circuit .

Branch circuit (literally translated as branch circuit) and Feeder circuit (literally translated as feeder circuit) both belong to Power circuit.

In this standard, the requirements of the Power circuit chapter are the focus of attention.

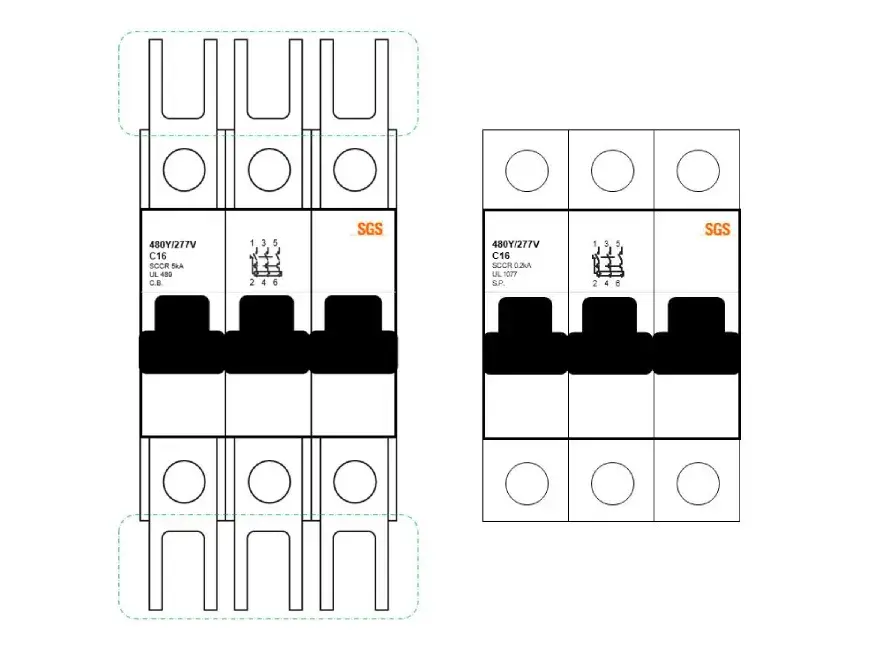

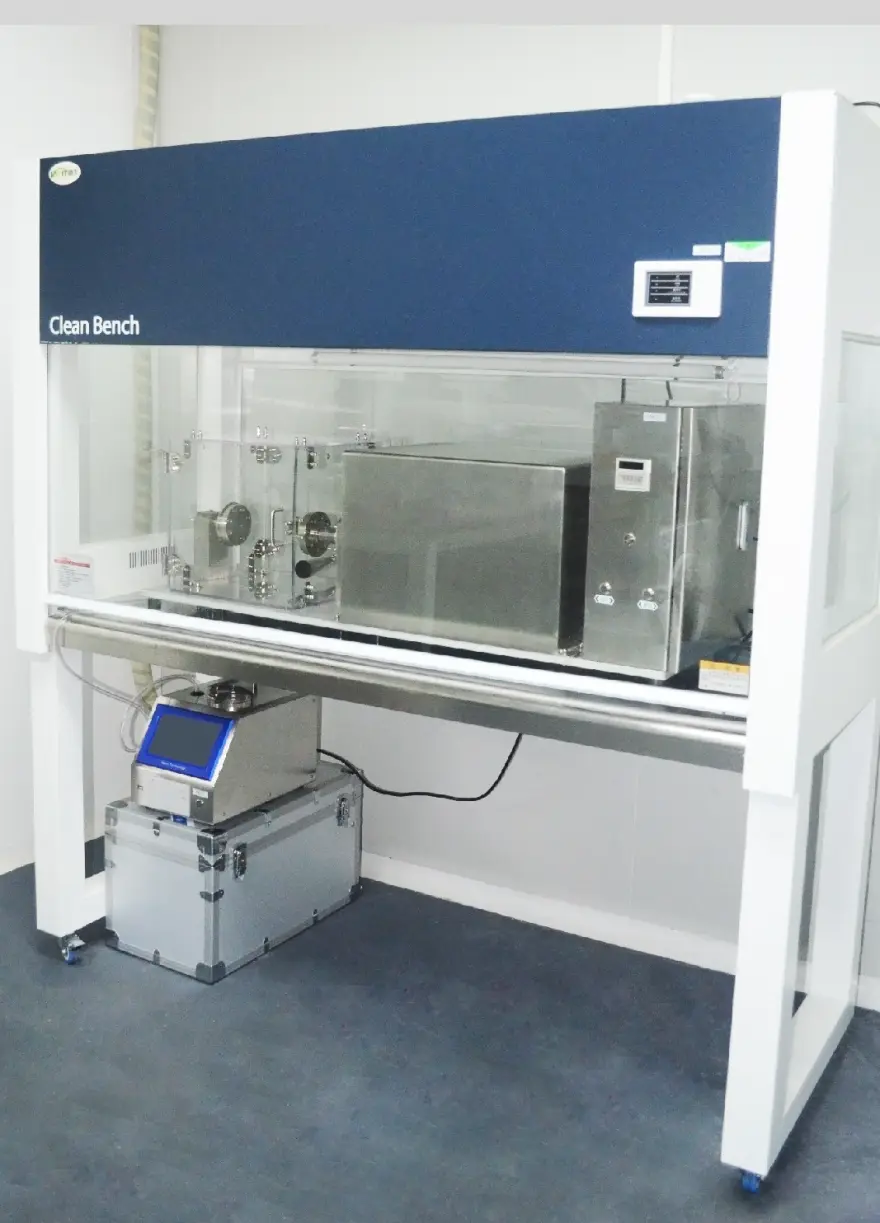

Compare the details of the left and right pictures

In the official standard:

UL 489 certified products are called Molded Case Circuit Breaker (literally translated as molded case circuit breaker );

UL 1077 certified products are called Supplementary Protectors.

As the name suggests, the additional protector of UL 1077 cannot be used as an overcurrent protection device alone, it only serves as additional protection .

Why only UL 489 circuit breakers can be selected for power circuit protection

At present, the protection of power circuits can only use UL 489 type circuit breakers. There are three main reasons:

01Direct requirements of the standard

In Section 31.1.7 of UL 508A, it is clearly stated that branch circuit protection of industrial control equipment must be UL 489 type molded case circuit breakers, and UL 1077 type overcurrent protection devices are not allowed to be used in power circuits. In Section 7.2.1.3 of NFPA 79, it is also clearly stated that supplementary overcurrent protective devices (i.e. supplementary protectors in the form of UL 1077) cannot be used for branch circuit protection.

And in the scope of application of section 1.1 of the original UL 1077 standard, it is also emphasized that the additional protector is only applicable to scenarios where branch circuit overcurrent protection is already equipped or not needed.

02Consideration of electrical clearance and creepage distance

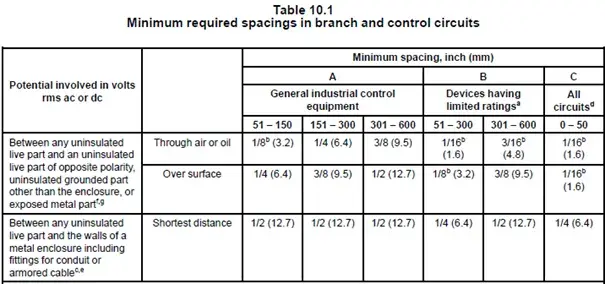

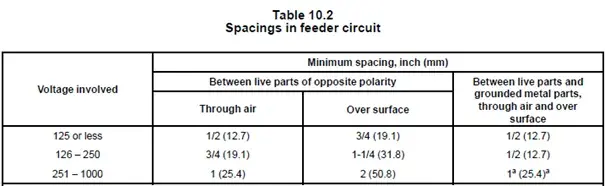

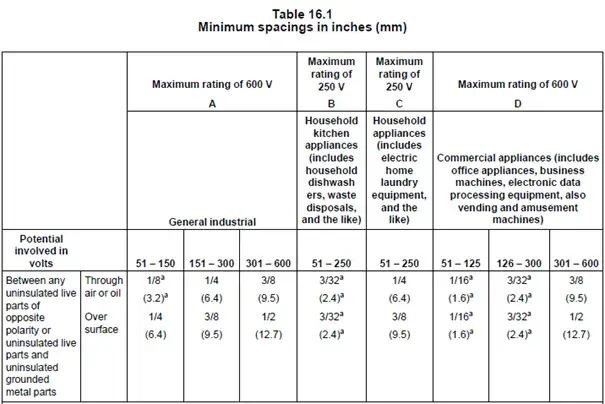

For the common North American 480V power supply system, refer to the Spacing requirements of Section 10 of UL 508A. According to Table 10.1, the phase-to-phase electrical clearance in the branch circuit is at least 9.5mm and the creepage distance is at least 12.7mm.

According to Table 10.2, the phase-to-phase clearance in the feeder circuit is at least 25.4 mm, and the creepage distance is at least 50.8 mm;

According to Figure 6.1 and Figure 6.3 of UL 508A, the boundary between the feeder circuit and the branch circuit is usually the branch circuit protection. Therefore, the branch circuit protection device also needs to meet the electrical clearance and creepage distance requirements of the feeder circuit.

In UL 489, the overcurrent protector that can be used in a 480V system (301-1000V) has an electrical clearance of at least 25.4mm between terminals and a creepage distance of at least 50.8mm, which can meet the requirements of UL 508A Table 10.1 and Table 10.2.

Note: Spacing through air or oil is translated as electrical clearance and Spacing over surface is translated as creepage distance for convenience only.

In UL 1077, overcurrent protectors that can be used in 480V systems (301-600V) have an electrical clearance of at least 9.5mm between terminals and a creepage distance of at least 12.7mm, which can meet the requirements of UL 508A Table 10.1 but cannot meet the requirements of Table 10.2.

This is one of the reasons why UL 1077 cannot provide branch circuit protection.

From the appearance, there is a huge difference between the two. The circuit breaker that complies with UL 489 (left picture) has a higher insulating partition, which can be used to increase the electrical clearance and creepage distance.

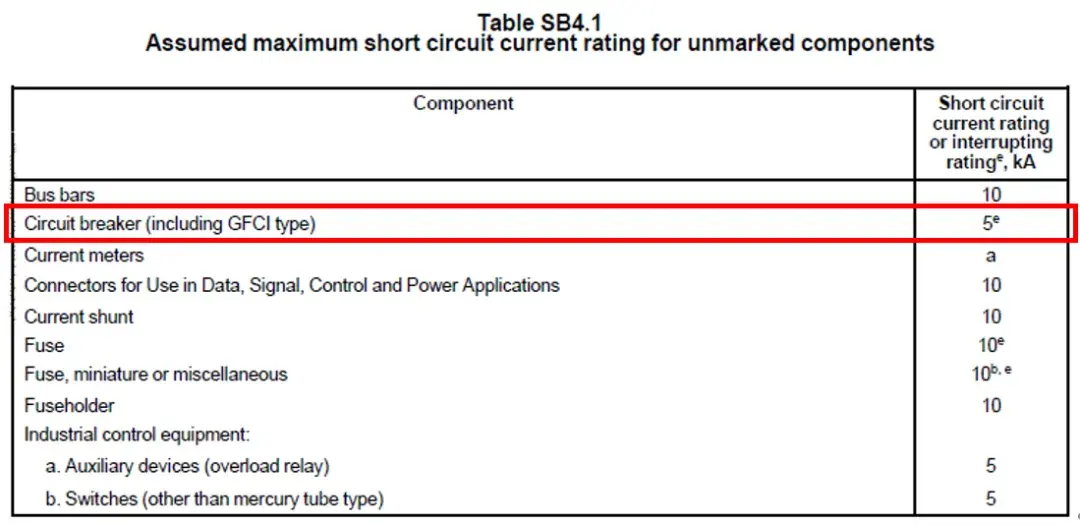

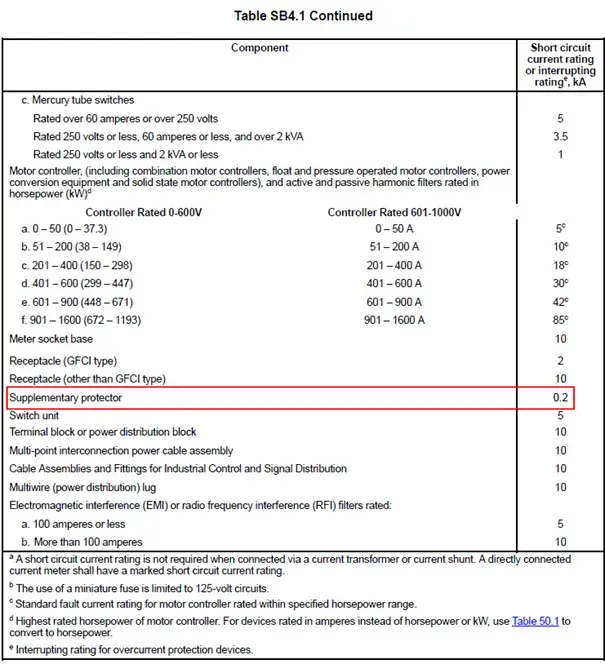

03 Limitation of rated short-circuit current SCCR

When calculating the SCCR of the entire cabinet, if the SCCR value is not marked on the housing of the protection device or switch, the SCCR value of the component is usually selected according to Table SB4.1 of Appendix SB of UL 508A. It can be seen that the typical SCCR value of the protection device that complies with UL 489 is 5kA, while the typical SCCR value of the protection device that complies with UL 1077 is only 0.2kA.

If UL 1077 additional protectors are used on the feeder circuit and branch circuit, the SCCR of the entire cabinet will be reduced and will not meet the use requirements.

In addition to the above, there are many other factors that affect why branch circuit protection can only use UL 489 circuit breakers. As a manufacturer of industrial control cabinets, when designing North American products for compliance, it is necessary to consider the standard requirements and select components that meet the standards, thereby saving rectification costs and speeding up the certification project progress.

Email:hello@jjrlab.com

Write your message here and send it to us

IECEE CBTL Testing Laboratory for IVD Medical Devi

IECEE CBTL Testing Laboratory for IVD Medical Devi

China OECD GLP-Certified Laboratory

China OECD GLP-Certified Laboratory

Packaging Validation ISO 11607 Test Report

Packaging Validation ISO 11607 Test Report

What is the ISO 11607-1 Packaging Validation Test?

What is the ISO 11607-1 Packaging Validation Test?

How to get an ISO 11737-1 Test Report?

How to get an ISO 11737-1 Test Report?

Orthopedic Implant Cleanliness Testing

Orthopedic Implant Cleanliness Testing

What is ISO 10993-23:2021 Irritation Testing?

What is ISO 10993-23:2021 Irritation Testing?

ISO 10993-23 Irritation Testing Laboratory

ISO 10993-23 Irritation Testing Laboratory

Leave us a message

24-hour online customer service at any time to respond, so that you worry!