ROHS Certification Testing for Metal Parts

The Importance of ROHS Testing for Metal Parts

ROHS testing for metal parts ensures that products meet the requirements of the European Union's "Directive on the Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment." This ensures the marketability and circulation of products within the EU. Any product manufactured in or imported into the EU must pass the ROHS testing standards. If the substance content exceeds the specified limits, the product cannot be sold on the market.

Benefits of ROHS Testing for Metal Parts

ROHS testing for metal parts benefits businesses by improving product environmental friendliness and competitiveness, meeting market demand and legal requirements. It ensures that metal parts reduce environmental pollution risks during production, usage, and disposal by limiting harmful substances like lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBB), and their ethers. This also helps protect the environment and human health.

ROHS Testing Standards for Metal Parts

ROHS testing is an important directive from the European Union that limits the use of certain hazardous substances in electrical and electronic equipment. Different countries and regions may have varying ROHS testing standards, but generally, the content of lead, mercury, cadmium, and hexavalent chromium in metal parts should not exceed 0.1% (1000ppm), and the content of polybrominated biphenyls and their ethers should not exceed 0.1% (1000ppm).

Cost of ROHS Testing for Metal Parts

The cost of ROHS testing for metal parts does not have a fixed standard and is influenced by various factors. The price generally ranges from $500 to $1500. The fee primarily depends on the following conditions:

1. The number of products being tested. Testing a small number of stainless steel pipe samples will be relatively inexpensive.

2. The number of testing items. If only the four main tests or the ten non-metal tests are performed, the cost may be around $550.

3. The material and composition complexity of the metal parts. If the material is simple and the composition is ordinary, such as in a stainless steel pipe, the testing is less difficult, and the cost remains stable. Conversely, the cost will be higher if the material is more complex.

ROHS Testing Process for Metal Parts

1. Prepare the samples.

2. Fill out the application form.

3. The testing agency conducts the analysis according to standard methods.

4. Based on the test results, determine whether the metal parts meet ROHS standards.

5. The testing agency issues a detailed report based on the test results.

Email:hello@jjrlab.com

Write your message here and send it to us

Toy Toxicology Testing CA

Toy Toxicology Testing CA

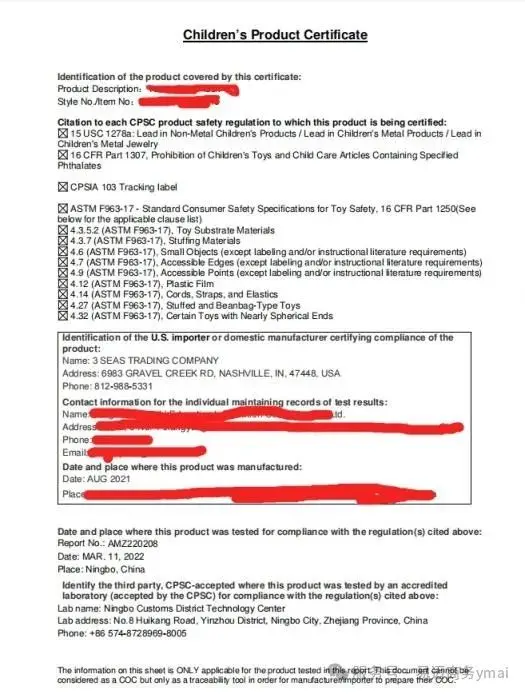

CPSIA Compliance for Children's Products

CPSIA Compliance for Children's Products

Food Contact Items Testing

Food Contact Items Testing

Energy Star Testing Laboratory

Energy Star Testing Laboratory

Do I Need to Test Every Color for CPSIA Compliance

Do I Need to Test Every Color for CPSIA Compliance

Accredited Medical Device Testing Lab

Accredited Medical Device Testing Lab

Safety Testing for Baby Wrap

Safety Testing for Baby Wrap

United States Electrical Plug Certification

United States Electrical Plug Certification

Leave us a message

24-hour online customer service at any time to respond, so that you worry!