Power Inductor AEC-Q200 Certification Test

The Necessity of Power Inductor AEC-Q200 Certification

Power Inductors are widely used in automotive electronics fields such as powertrains, engine control, transmission control, LED drivers, ABS braking systems, EPS, radar systems, and camera control systems. Automotive applications have very high reliability requirements, and AEC-Q200 certification provides the performance and reliability levels needed for automotive and high-reliability industrial applications.

Most automotive manufacturers currently require parts to have aec certification. AEC certification is an internationally accepted standard for automotive components. Passing AEC certification means that the product can be used in automobiles, so Power Inductor AEC-Q200 certification is very necessary.

Application Requirements for Automotive-Grade Power Inductors

Automotive-grade Power Inductors are magnetically shielded, have low DC resistance, and have a high saturation current of up to 4.4A. They are high-temperature resistant, with an operating temperature range of -40 to +125°C, an ambient temperature of up to 85°C, and a maximum temperature rise of 40°C, meeting an operating temperature of up to 155°C.

Power Inductor AEC-Q200 Certification Test Items

AEC-Q200 is a reliability validation standard for automotive-grade passive components. Different products need to pass different AEC-Q200 reliability test items. Below are the Power Inductor AEC-Q200 certification test items and additional requirements:

1. Electrical Test Before and After Stress Test

- Test Method: UserSpec. User Specification

- Additional Requirements: Tests must be conducted at 25±5°C. In addition to applicable stress test standards and additional requirements specified in Table 2.

2. High-Temperature Storage

- Test Method: MIL-STD-202 Method 108

- Additional Requirements: Store the device at the highest rated temperature for 1000 hours without power. Other tests shoULd be conducted within 24±4 hours after this test.

3. Temperature Cycling

- Test Method: JES D22 Method JA-104

- Additional Requirements: 1000 cycles (-55°C to +125°C); other tests should be conducted within 24±4 hours after the test. The dwell time at each temperature should not exceed 30 minutes, and the transition time should not exceed 1 minute.

4. Biased Humidity

- Test Method: MIL-STD-202 Method 103

- Additional Requirements: Place at 85°C and 85% humidity for 1000 hours. Conduct other tests within 24±4 hours after the test.

5. Operational Life

- Test Method: MIL-STD-202 Method 108

- Additional Requirements: Conditions D (1000h), TA=125°, in a steady state. Conduct tests within 24±4 hours after the test, and place the device at the maximum rated temperature and voltage.

6. External Visual

- Test Method: MIL-STD-883 Method 2009

- Additional Requirements: Inspect device structure, marking, and workmanship quality without Electrical Testing.

7. Physical Dimension

- Test Method: JESD22 Method JB-100

- Additional Requirements: Verify physical dimensions per applicable device specifications. Note: No electrical testing requiRED per user and supplier specifications.

8. Terminal Strength (Pin)

- Test Method: MIL-STD-202 Method 211

- Additional Requirements: Perform only pin and pin adhesion strength tests. Conditions A (910g), C (1.13kg), E (1.45kg-mm).

9. Resistance to Solvents

- Test Method: MIL-STD-202 Method 215

- Additional Requirements: Applicable to devices with marking and/or coating. Add water-washable cleaner OKEM cleaner (6% concentration of Oakite cleaner).

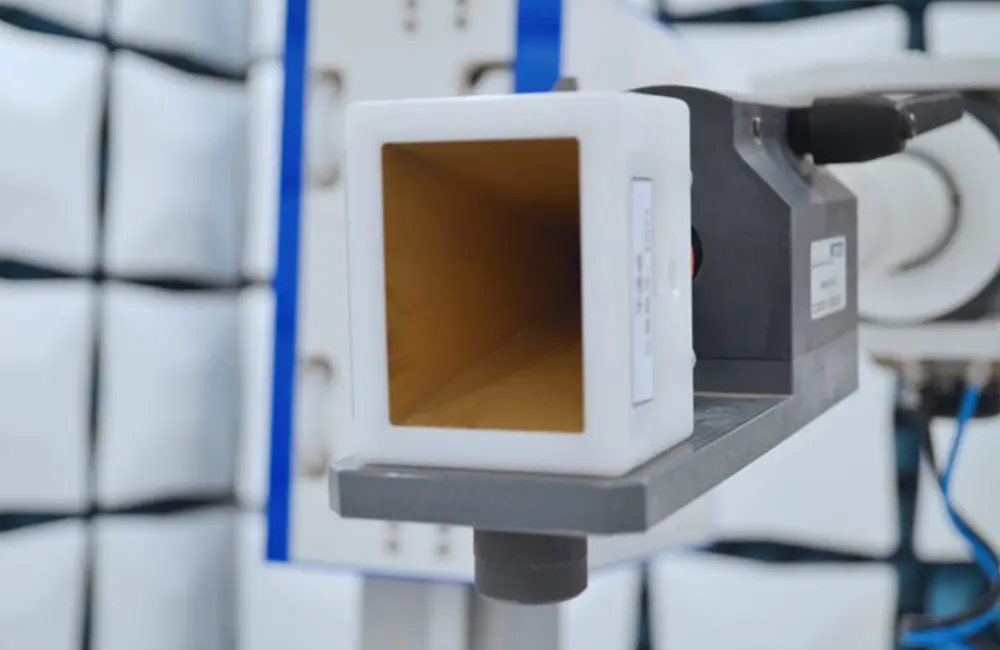

10. Mechanical Shock

- Test Method: MIL-STD-202 Method 213

- Additional Requirements: Half-sine pulse, XYZ three-direction impact, duration 0.5ms, peak acceleration 1500g.

11. Vibration

- Test Method: MIL-STD-202 Method 204

- Additional Requirements: Test frequency range is 10-2000 Hz, force is 5g/s, duration 20 minutes, 12 cycles per direction.

12. Resistance to Soldering Heat

- Test Method: MIL-STD-202 Method 210

- Additional Requirements: Condition B, samples not preheated. Pin devices dipped to 1.5mm, surface mount components to 0.75mm.

13. ESD (Electrostatic Discharge)

- Test Method: AEC-Q200-002 Or ISO/DIS10605

14. Solderability

- Test Method: J-STD-002

- Additional Requirements: Applicable to pin and surface mount devices, no electrical testing, magnification 50x. Pin products method A @ 235℃, surface mount components method B 4 hours @ 155℃ dry heat @ 235℃.

15. Electrical Characterization

- Test Method: UserSpec. User Specification

- Additional Requirements: Perform parameter testing per lot and sample size requirements. Summarize and list the minimum, maximum, average, and standard deviation of devices at room and low/high operating temperatures. Measure parameters CP, DF, IR at low/room/high temperatures. Refer to the parameter table for recommendations.

16. Flammability

- Test Method: UL-94

- Additional Requirements: V-0 or V-1 is acceptable.

17. Board Flex

- Test Method: AEC-Q200-005

- Additional Requirements: Applicable only to MLCC, support time at least 60 seconds.

18. Terminal Strength (SMD)

- Test Method: AEC-Q200-006

- Additional Requirements: Apply thrust parallel to the ceraMIC body (17.7N/1.8Kg), terminals should not fall off, ceramic body should not be damaged or broken.

How Much Does Power Inductor AEC-Q200 Certification Cost?

The cost of Power Inductor AEC-Q200 certification typically refers to the testing fees charged by third-party testing agencies. To evaluate the cost, customers need to provide detailed specifications, and the testing items are determined based on the AEC-Q200 standard. Not all AEC-Q200 items need testing. Once the test items are confirmed, a quote can be provided based on the test items. AEC-Q200 testing includes many long-term environmental reliability tests, and the certification process typically takes 2-3 months under normal circumstances.

Email:hello@jjrlab.com

Write your message here and send it to us

LED Lighting EMC Testing Service

LED Lighting EMC Testing Service

EU REACH Compliance Testing Services

EU REACH Compliance Testing Services

Electronic and Electrical Reliability Testing Serv

Electronic and Electrical Reliability Testing Serv

Electronic & Electrical Safety Compliance Test

Electronic & Electrical Safety Compliance Test

Shenzhen Electronic Electromagnetic Compatibility

Shenzhen Electronic Electromagnetic Compatibility

How to Test IP68 Rating

How to Test IP68 Rating

Differences Between FDA and LFGB for Food Contact

Differences Between FDA and LFGB for Food Contact

Process and Precautions for Amazon CPC Certificate

Process and Precautions for Amazon CPC Certificate

Leave us a message

24-hour online customer service at any time to respond, so that you worry!