Orthopedic Implant Cleanliness Testing

The cleanliness of orthopedic implants is a key step in evaluating their biocompatibility and controlling microbial load during the sterilization process. Cleaning is often regarded as a critical procedure to remove contaminants left from previous processing stages, which can be achieved through mechanical, physical, or chemical methods. Several factors influence the ease of achieving cleanliness, including the chemical properties of the product surface, the nature of the contaminants, the cleaning process, the product design (e.g., assembly parts, blind holes, deep holes, etc., which can increase cleaning difficulty), as well as the product surface area and porosity.

Cleanliness Evaluation Process

1. Design of Cleaning Process

The cleaning process for the product should be thoroughly designed to meet predefined cleanliness acceptance standards. Manufacturers must conduct a risk analysis based on the product’s processing techniques and reasonably design the cleaning steps for key processes and final cleaning, verifying and confirming them to minimize contamination risks.

2. Validation of Cleaning Process

Both the key process cleaning and final cleaning must be validated to ensure the process consistently produces products that meet cleanliness requirements.

3. Sampling, Processing, and Testing

During the risk analysis of the cleaning process, an appropriate sampling plan should be established. If applicable, the sampling plan should be based on reasonable statistical principles to determine the sample size. When confirming under worst-case conditions, each worst-case scenario should be tested. When establishing process reproducibility, at least three cleaning batches should be tested.

4. Cleanliness Evaluation

Testing methods and cleanliness acceptance standards include:

- Visual Inspection: Visual inspection standards after cleaning should be established by the manufacturer (EN 13018).

- Biological Load: If the cleaning process aims to reduce biological load, biological load testing should be done according to ISO 11737-1, ensuring that the expected biological load level is low enough to guarantee the sterilization method achieves the desired sterility assurance level.

- Bacterial Endotoxins: For cleaning aimed at reducing endotoxin contamination, the testing should follow validated methods, such as those using Limulus Amebocyte Lysate (LAL), as per pharmacopeial standards. Each implant’s bacterial endotoxin level should not exceed 20 EU (USP 85, YY/T 0618).

- Organic Contaminants: Various methods exist for detecting organic contaminants. The method chosen should depend on the type of contamination, material of the implant, and sensitivity of the analytical method. Total Organic Carbon (TOC) or other applicable methods may be used to detect water-soluble organic contaminants, while Total Hydrocarbons (THC) may be used for hydrocarbons in non-polar solvents. Limits for TOC and THC are defined in various standards.

- Inorganic Contaminants: Heavy metals (arsenic, cadmium, lead, mercury) should be tested using methods like ICP-MS and USP <233>.

- Particle Contamination: Standards like AAMI TIR42 provide guidelines.

- Cytotoxicity: Testing should follow ISO 10993-5 and GB/T 16886.5.

5. Ongoing Process Validation

To ensure cleanliness requirements are consistently met, regular monitoring of key process parameters and environmental conditions is essential.

Selection of Extraction Solution and Extraction Time

The extraction ratio (surface area or mass/volume) varies depending on the thickness of the material. For instance:

- For materials less than 0.5 mm thick, the extraction ratio is 6 cm²/mL (for films, thin sheets, tube walls).

- For materials between 0.5 to 1.0 mm thick, the ratio is 3 cm²/mL (for tube walls, thick sheets, small molded parts).

- For materials over 1.0 mm thick, the ratio is 3 cm²/mL for large molded parts, or 1.25 cm²/mL for elastic seals.

For irregularly shaped solid devices, such as powders, spheres, and foam materials, the extraction ratio is typically 0.2 g/mL.

Note: No standardized methods currently exist for testing absorbents and hydrogels. A recommended approach involves measuring the absorption of the extraction medium per 0.1g or 1.0cm² of material, and adjusting the extraction mixture accordingly.

Relevant Standards

- GB/T 44876-2024: Surgical Implants - Cleanliness of Orthopedic Implants - General Requirements

- ISO 19227-2018: Surgical Implants - Cleanliness of Orthopedic Implants - General Requirements

- GB/T 16886.12-2017: Biological Evaluation of Medical Devices - Part 12: Sample Preparation and Reference Materials

- ISO 10993-12-2021: Biological Evaluation of Medical Devices - Part 12: Sample Preparation and Reference Materials

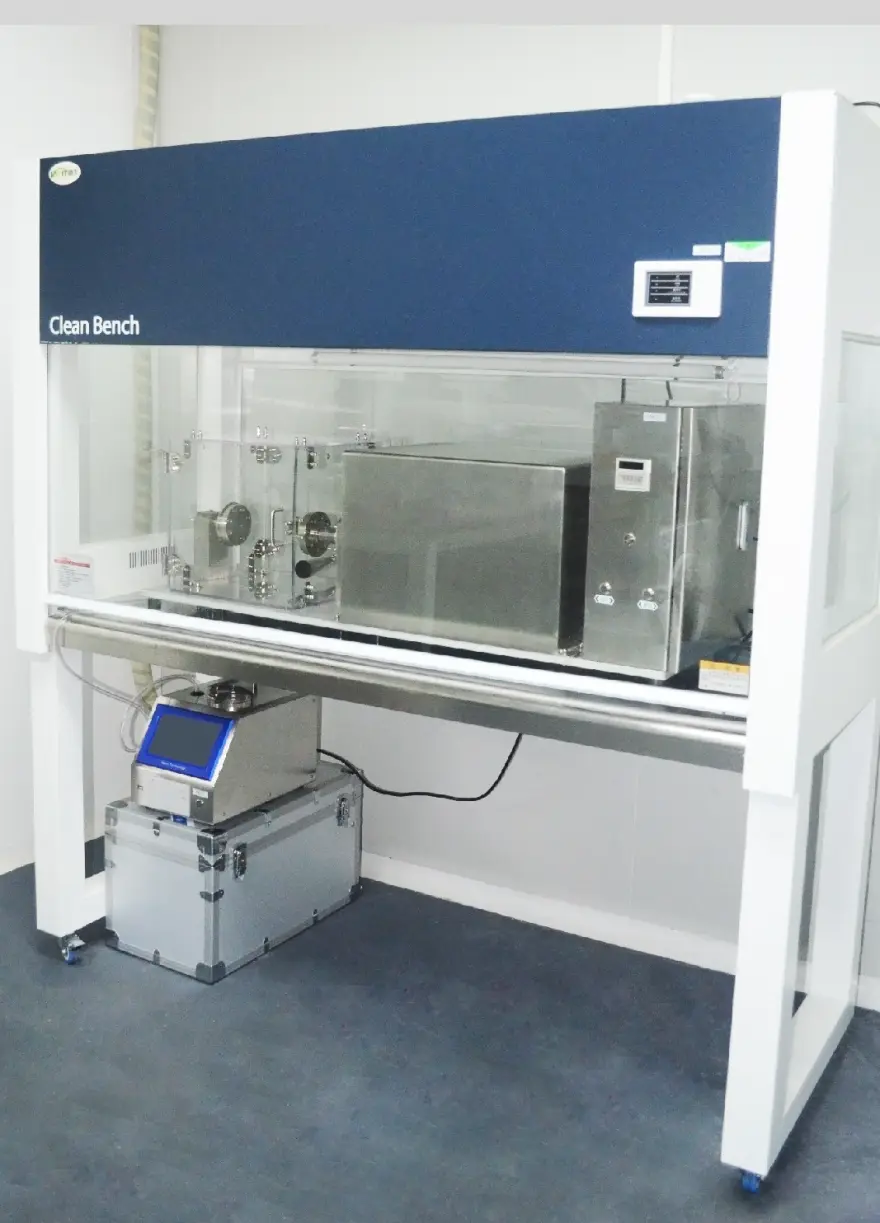

Laboratory Configuration

The China JJR Laboratory is equipped with advanced testing equipment, such as AAS, GFAAS, ICP-AES, ICP-MS, UV-VIS, IC, GC, GC-MS, LC, LC-MS/MS, TOC, LPC, and other precision instruments. These capabilities ensure compliance with testing requirements outlined in ISO 19227-2018 "Cleanliness of Orthopedic Implants" and GB/T 44876-2024 "Surgical Implants - Cleanliness of Orthopedic Implants - General Requirements."

Email:hello@jjrlab.com

Write your message here and send it to us

Packaging Validation ISO 11607 Test Report

Packaging Validation ISO 11607 Test Report

What is the ISO 11607-1 Packaging Validation Test?

What is the ISO 11607-1 Packaging Validation Test?

How to get an ISO 11737-1 Test Report?

How to get an ISO 11737-1 Test Report?

Orthopedic Implant Cleanliness Testing

Orthopedic Implant Cleanliness Testing

What is ISO 10993-23:2021 Irritation Testing?

What is ISO 10993-23:2021 Irritation Testing?

ISO 10993-23 Irritation Testing Laboratory

ISO 10993-23 Irritation Testing Laboratory

EMI Emissions Testing

EMI Emissions Testing

EMC Standards for Medical Devices

EMC Standards for Medical Devices

Leave us a message

24-hour online customer service at any time to respond, so that you worry!