New Energy Vehicle Charging Gun Testing

With the rapid adoption of new energy vehicles, the charging gun, serving as a critical component connecting vehicles to charging stations, plays a pivotal role in ensuring safe charging. To meet the demands of everyday use, rigorous testing and certification of charging guns are essential. China’s JJR Laboratory, a professional third-party testing organization, has introduced a full suite of testing equipment, enabling comprehensive testing and certification services for charging guns in accordance with various domestic and international standards.

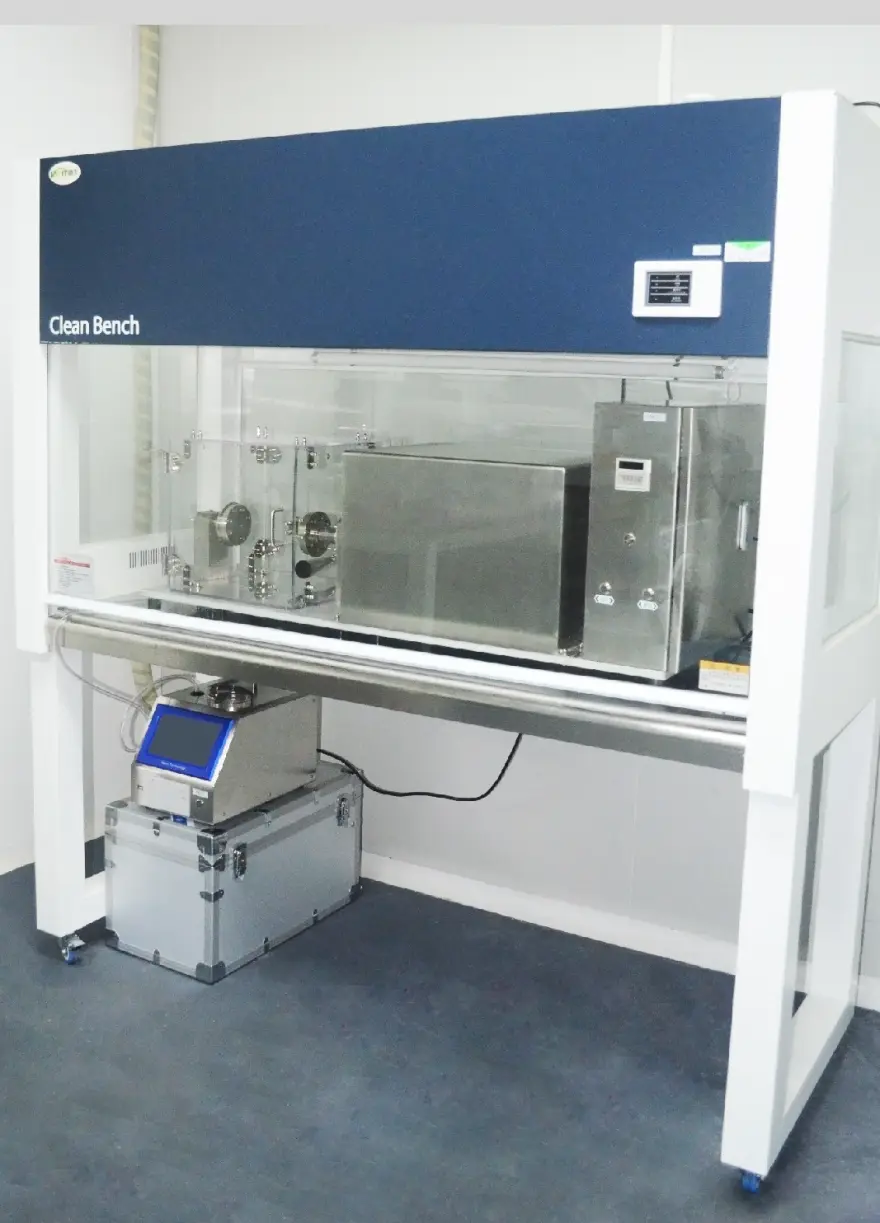

Core Testing Equipment for Charging Guns

- Vehicle Overrun Testing Machine

- Charging Interface Cable Flexing Tester

- Mechanical Strength Testing Equipment for Charging Guns

- Plug-and-Unplug Lifecycle Tester

- Resistive and Inductive Load Bank

- High-Power Power Supply System

Charging Gun Testing Standards

China’s JJR Laboratory conducts charging gun testing based on multiple standards to ensure compliance with all performance requirements. Common testing standards include:

- IEC 62196-1:2022: Plugs, socket-outlets, vehicle connectors, and vehicle inlets – Conductive charging of electric vehicles – Part 1: General requirements.

- IEC 61851-1:2017: Electric vehicle conductive charging system – Part 1: General requirements.

- UL 2251:2020: Plugs, receptacles, and connectors for electric vehicles.

- GB/T 20234.1-2023: Connection devices for conductive charging of electric vehicles – Part 1: General requirements.

- GB/T 20234.2-2023: Connection devices for conductive charging of electric vehicles – Part 2: AC charging interface.

- GB/T 20234.3-2023: Connection devices for conductive charging of electric vehicles – Part 3: DC charging interface.

- GB/T 18487.1-2022: Electric vehicle conductive charging system – Part 1: General requirements.

Leveraging advanced testing equipment and a professional technical team, JJR Laboratory provides comprehensive testing services for charging guns’ performance and reliability metrics in line with standards such as IEC 62196-1:2022.

Through rigorous testing, JJR ensures charging guns meet mechanical, electrical, and environmental performance standards, safeguarding the safety of electric vehicle charging. Whether during product design and development or pre-market quality verification, JJR Laboratory offers all-encompassing technical support to help enterprises enhance product quality and maintain market competitiveness.

Charging Gun Testing Categories

1. General Requirements

- Appearance and Structural Requirements: Ensures the charging gun’s appearance meets standards, has no defects, and features robust construction.

- Dimensional and Type Requirements for Charging Interfaces: Verifies that interface dimensions comply with standards to ensure compatibility with different charging equipment.

- Screws, Current-Carrying Components, and Connection Requirements: Ensures the firmness of screws and connections for safe current transmission.

- Terminal and End Requirements: Evaluates the quality of terminals and ends to ensure stable electrical connections.

- Electric Shock Protection Requirements: Tests anti-electric shock measures to ensure user safety during operation.

2. Electrical Performance

- Grounding Measures: Evaluates the grounding system to ensure safe electrical grounding.

- Breaking Capacity: Assesses the gun’s ability to break the circuit under overload conditions.

- Surface Temperature: Monitors surface temperatures during operation to prevent overheating risks.

- Temperature Monitoring Requirements: Tests the system's ability to detect and respond to temperature anomalies.

- Insulation Resistance and Dielectric Strength: Ensures electrical safety under various environmental conditions.

3. Durability Testing

- Locking Mechanism Durability: Evaluates the durability of locking mechanisms for stable performance over prolonged use.

- Normal Operation Durability (Lifespan): Simulates usage scenarios to test durability after repeated plug-and-unplug cycles.

- Contact Durability: Assesses the durability of connectors to ensure consistent contact during frequent use.

- Switch Component Durability: Tests the longevity and reliability of internal switch components.

4. Environmental Reliability

- High and Low Temperature Resistance: Simulates extreme temperature conditions to test resilience.

- Humidity Resistance: Evaluates performance under high-humidity conditions.

- Temperature Shock: Assesses stability under rapid temperature changes.

- IP Protection Rating: Tests dust and water resistance for reliability in harsh environments.

5. Mechanical Reliability

- Vehicle Overrun Test: Simulates the mechanical strength of the charging gun under vehicle pressure.

- Cable Connection Strength (Tension and Torsion Test): Evaluates connection strength under stress.

- Mechanical Strength (Pendulum Impact, Flexing, etc.): Ensures impact and bending resistance during usage.

- Vibration/Shock Testing: Simulates vibrations and shocks during transportation and use.

- Offset Operation Test: Assesses mechanical performance under improper operations.

6. Material Testing

- Aging Resistance of Rubber and Thermoplastic Materials: Tests material durability over time to ensure longevity.

- Corrosion and Rust Resistance: Assesses the outer shell’s ability to resist corrosion and rust in harsh environments.

- Heat, Flame, and Tracking Resistance: Tests material performance under extreme conditions.

- Restricted Substances Testing (ELV, ROHS, SOC, etc.): Ensures materials are free of hazardous substances and meet environmental standards.

Why Choose JJR Laboratory?

1. Brand Trust: Established in 1998, recognized by CNAS and CMA, and designated as a National SME Public Technology Service Platform.

2. Comprehensive Certifications: Recognized by multiple domestic and international organizations with widely trusted testing reports.

3. International Standards: Operates in compliance with ISO/IEC 17025 and over 10 international and domestic standards.

4. Service Excellence: Provides efficient, one-stop testing and certification services, trusted by numerous renowned domestic and international enterprises.

Email:hello@jjrlab.com

Write your message here and send it to us

Packaging Validation ISO 11607 Test Report

Packaging Validation ISO 11607 Test Report

What is the ISO 11607-1 Packaging Validation Test?

What is the ISO 11607-1 Packaging Validation Test?

How to get an ISO 11737-1 Test Report?

How to get an ISO 11737-1 Test Report?

Orthopedic Implant Cleanliness Testing

Orthopedic Implant Cleanliness Testing

What is ISO 10993-23:2021 Irritation Testing?

What is ISO 10993-23:2021 Irritation Testing?

ISO 10993-23 Irritation Testing Laboratory

ISO 10993-23 Irritation Testing Laboratory

EMI Emissions Testing

EMI Emissions Testing

EMC Standards for Medical Devices

EMC Standards for Medical Devices

Leave us a message

24-hour online customer service at any time to respond, so that you worry!