Do I Need to Test Every Color for CPSIA Compliance?

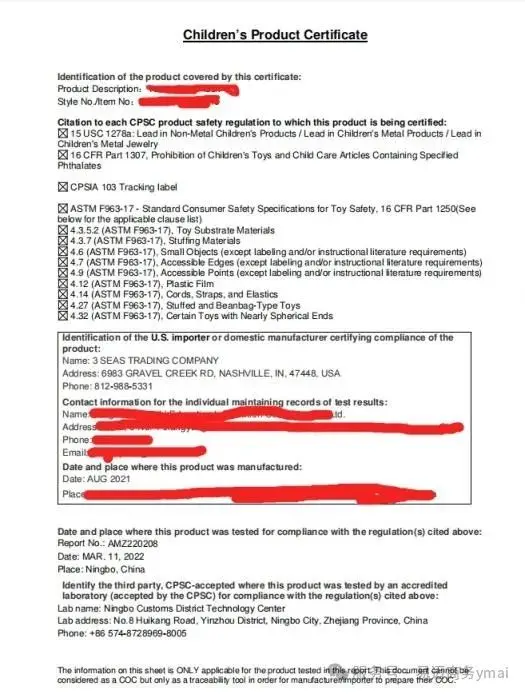

What Is Consumer Product Safety Improvement Act Compliance (CPSIA Compliance) In the US, Consumer Product Safety Improvement Act applies to certain consumer products (especially children's items). CPSIA sets stringent limitations on hazardous substances like lead and phthalates as well as mandating third-party testing and certification to ensure product safety.

Should I Test All Colors?

1. Core Requirements of the Regulation

CPSIA addresses harmful materials rather than colors themselves, for instance if your product contains coatings, paints, dyes or plastics it should be tested for lead and phthalates to comply.

Different colors require distinct formulations or processes (for instance, different pigments). Thus, multiple tests may be needed before making your decision.

2. Testing Different Color Materials

Various situations necessitate testing different colored materials separately:

- Color variation stemming from differing pigments/dyes: Due to various pigments' chemical components (for instance azo dyes containing heavy metals), each pigment needs to be tested individually for compliance before it enters production or comes in contact with children. - Component bearing the color contains independent components or comes into direct contact with them:

Example: if a toy features red buttons and blue handles made from different materials, these must each be tested independently to comply with regulations in their target markets. - Individual components will require separate testing processes:

Some countries/regions (e.g. EU REACH and US CPSIA) require testing of product parts that come into direct contact with children; color differences could even count as separate parts.

3. When Testing Is Not Necessary

When the color variation stems from printing processes rather than differences in material characteristics - such as being non-porous - testing might not be required to achieve consistency between pieces.

Example: if the same plastic base is printed with multiple colors of printing layers that do not come into direct contact with children and are very thin, separate testing may not be required (consult your testing agency before proceeding with testing).

Chemical analysis verifies that all colors of materials contain identical composition: If suppliers can offer reports verifying composition consistency (such as spectral analysis confirming no difference in pigments), redundant tests may be reduced significantly.

How Can You Tell If Testing Is Needed?

1. Determine Your Product's Purpose and Applicable Regulations:

Toy products intended for children must comply with applicable federal, state and local regulations (such as ASTM F963 for toys) prior to being made commercially available for sale.

If the product in question is for adults only, however, other regulations (REACH or Proposition 65 in California) must still be observed.

2. Analyse Material Composition:

First, identify all materials included in your product including colors (such as plastics, textiles and metal coatings) in its composition before checking if any may contain restricted substances.

3. Consult Testing Agencies or Regulatory Experts: Provide the product details (material, color, intended use and sales region) to professionals for guidance as to if separate color testing is needed.

Recommendations Regarding Compliance Testing

1. Prioritize Testing High-Risk Materials:

Place emphasis on parts which come into direct contact with children such as toy handles or those which contain bright colors as certain pigments may contain heavy metals.

2. Keep Test Reports and Supply Chain Documents Secure:

Request that suppliers supply Material Safety Data Sheets (MSDSs) and complianCE certifications that reduce unnecessary testing costs.

3. Monitor Regulatory Updates:

Regulations such as the Consumer Products Safety Information Act may alter substance limits or increase control scope over time, so it's essential that regular checks be made against current requirements in order to stay compliant.

Principle of Testing:

Testing should focus on materials/parts rather than color itself. If different hues correspond with distinct materials or formulations, testing of each should occur separately whereas if their hue doesn't alter material composition it might be waived off altogether.

Contact JJR Lab (or another testing agency of your choice) for an initial risk evaluation and then design a testing plan based on its product's actual circumstances to meet market regulations and ensure its success on target markets.

Email:hello@jjrlab.com

Write your message here and send it to us

Toy Toxicology Testing CA

Toy Toxicology Testing CA

CPSIA Compliance for Children's Products

CPSIA Compliance for Children's Products

Food Contact Items Testing

Food Contact Items Testing

Energy Star Testing Laboratory

Energy Star Testing Laboratory

Do I Need to Test Every Color for CPSIA Compliance

Do I Need to Test Every Color for CPSIA Compliance

Accredited Medical Device Testing Lab

Accredited Medical Device Testing Lab

Safety Testing for Baby Wrap

Safety Testing for Baby Wrap

United States Electrical Plug Certification

United States Electrical Plug Certification

Leave us a message

24-hour online customer service at any time to respond, so that you worry!