Medical Device Package Testing

Medical device package testing is a critical aspect of the medical device industry. Its purpose is to ensure that medical devices remain safe and effective during transportation, storage, and use. Since medical devices are often used in life-critical situations, any oversight in packaging design or testing can have severe consequences. Scientific package testing not only ensures the safety of the device but also extends its lifespan while REDucing the risks of contamination and damage. This article delves into the key steps and significance of medical device package testing.

Overview of Medical Device Package Testing

Medical device package testing verifies whether packaging materials, designs, and structures can adequately protect devices. These tests evaluate the packaging's resistance to various environmental conditions such as temperature, humidity, pressure, shock, and vibration. This ensures that medical devices remain intact and safe during transportation and storage.

Testing must comply with international standards (e.g., ISO 11607, ASTM) and national standards (e.g., GB/T 19633.1). Additionally, testing procedures shoULd be tailored to the device's characteristics, usage scenarios, and transportation requirements. The testing scope typically includes material selection, packaging seal integrity testing, durability testing, and aging tests.

Common Standards and Methods

1. Accelerated Aging: Simulates the aging process using ASTM F1980 or YY/T 0681.1 to evaluate durability and performance over time.

2. Burst Strength Testing: Assesses the packaging's resistance to pressure based on ISO 2758 or ASTM F1140/F2054.

3. Vacuum Leak Test: Uses ASTM D3078 or GB/T 15171 to ensure the packaging is sealed properly.

4. Sterile Barrier Seal Integrity: Validates seal integrity with ASTM F1929 or ASTM F1886/F1886M.

5. Peel Properties: Measures adhesive strength per EN 868-5 Appendix E or YY/T 0681.2.

6. Seal Strength: Tests seal resistance to pressure using ASTM F88/F88M or EN 868-5.

7. Air Permeability: Assesses breathability according to ISO 5636-3 or ASTM F2981.

8. Flex Durability: Evaluates friction resistance with ASTM F392 or YY/T 0681.12.

9. MICrobial Barrier: Validates protection against microbes using ASTM F1608 or YY/T 0681.10.

10. Tear Resistance: Tests material strength per GB/T 455 or ASTM D1922.

11. Oxygen Transmission Rate: Verifies gas barrier properties using iso 11607-1 Annex C.

Key Steps in Medical Device Package Testing

1. Material Selection and Validation

The choice of materials directly affects packaging performance. Sterile devices require materials with excellent barrier properties to prevent microbial intrusion, while larger devices demand high-strength outer packaging to resist mechanical damage. Validation includes tests for durability, microbial barrier performance, and biocompatibility.

2. Packaging Seal Integrity Testing

Seal integrity is crucial to maintaining a sterile environment. Methods such as bubble testing, dye penetration, and vacuum decay are used to detect micro-cracks or seal defects, ensuring packaging integrity.

3. Durability Testing

Durability tests simulate transportation conditions such as vibration, drops, and compression to verify packaging's ability to withstand harsh environments.

4. Aging Tests

Aging tests evaluate the long-term stability of packaging materials under varying temperature and humidity conditions to ensure consistent protective performance.

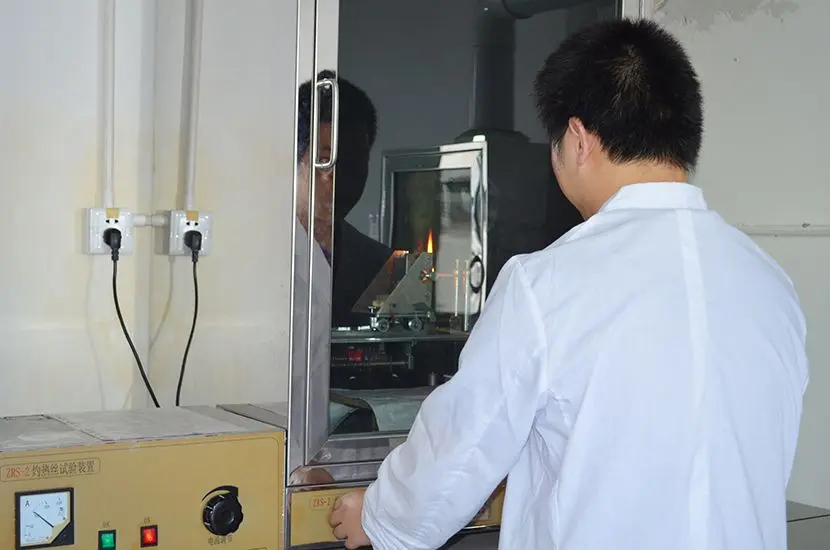

5. Microbial Barrier Testing

This step verifies the sterile barrier's ability to block microbial penetration, critical for ensuring device sterility and patient safety.

Significance of Package Testing in the Medical Device Industry

1. Minimizing Damage Risks: Rigorous testing reduces the likelihood of damage during transportation and storage.

2. Extending Shelf Life: Ensures packaging stability, reducing waste from packaging failures.

3. Enhancing Market Competitiveness: High-standard testing ensures compliance with international regulations and smooth market entry.

The Need for Professional Laboratories

Medical device package testing is a highly specialized field involving complex technologies and standards. Choosing a certified laboratory is essential as its technical capabilities and expertise directly influence the accuracy and reliability of test results.

China JJR Laboratory

As a leading medical device testing laboratory in China, JJR Laboratory offers:

- Comprehensive Testing Services: Material validation, seal integrity testing, durability testing, and aging tests.

- Globally Recognized Reports: Compliant with EU, FDA, and other global regulations.

- Diverse Expertise: Additional testing services include biocompatibility, electrical safety, and chemical characterization.

By choosing JJR Laboratory, you gain professional and efficient testing services to ensure product safety and compliance, providing strong support for entering global markets.

Scientific package testing not only ensures the safety and effectiveness of medical devices but also fulfills the responsibility of safeguarding every user's health and safety.

More:CE Certification mark | UL Certification cost | RCM Certification | UN38.8 battery

Email:hello@jjrlab.com

Write your message here and send it to us

How Do You Get a CE Mark

How Do You Get a CE Mark

IEC 60529 IP Rating Ingress Protection Standard

IEC 60529 IP Rating Ingress Protection Standard

IEC 60601-1 Medical Electrical Equipment Basic Saf

IEC 60601-1 Medical Electrical Equipment Basic Saf

European Authorized Representative Medical Devices

European Authorized Representative Medical Devices

EU Waste Electrical and Electronic Equipment Direc

EU Waste Electrical and Electronic Equipment Direc

How to Get CE Approval

How to Get CE Approval

Accelerated Ageing Test

Accelerated Ageing Test

IP Ingress Protection Testing

IP Ingress Protection Testing

Leave us a message

24-hour online customer service at any time to respond, so that you worry!