Medical Device EMC Rectification Services

The EMC (Electromagnetic Compatibility) testing and rectification of medical devices directly impacts patient safety and device reliability, and must strictly comply with regulatory standards such as IEC 60601-1-2 (Medical Electrical Equipment - EMC Requirements). Below are key considerations for EMC testing and rectification of medical devices, covering critical test items and special requirements:

Specificity of EMC Testing for Medical Devices

1. Higher Safety Standards:

Medical devices demand extremely low leakage currents and strong anti-interference capabilities, especially for life-supporting equipment (e.g., ventilators, pacemakers).

Test limits can be more stringent than for industrial equipment (e.g., radiated emissions may need to be reduced by an extra 3–10dB in specific frequency bands).

2. Risk Classification:

Devices are classified based on use into life-support (Class A/B) and non-life-support categories, with different rectification priorities.

3. Continuous Operation Requirement:

Devices must simulate clinical operating conditions during testing (e.g., ECG machines must connect to simulated loads), and cannot lose functionality due to interference.

Key Test Items and Rectification Points

1. Radiated Emissions (RE) & Conducted Emissions (CE)

• Common Issues:

o High-frequency surgical and ultrasound equipment often exceed limits in the 30MHz–1GHz range.

o Switching power supplies or motor drivers generate significant conducted noise.

• Rectification Focus:

o Use medical-grade EMI filters (e.g., SCHURTER or TDK type B) at power input, meeting withstand voltage of 2×Uₙ + 1000V.

o Signal lines should use low-capacitance TVS diodes (e.g., ≤1pF) to prevent signal distortion.

o Use medical-grade shielded enclosures (e.g., stainless steel housing), ensuring continuous contact at seams with conductive gaskets (e.g., copper braid).

o Openings such as displays should include conductive glass or metallic mesh.

o Prioritize shielding:

o Filter design:

2. Electrostatic Discharge (ESD) Immunity

• High-Risk Points:

o Operator interfaces (e.g., touchscreens, buttons), patient connection ports (e.g., electrodes, sensors).

• Rectification Measures:

o Series 100Ω resistors and parallel TVS diodes (e.g., ESD5Z5.0T1G) on button signal lines.

o Use optocoupler or transformer isolation to ensure patient leakage current <10μA (required for CF-type devices).

o Ground metallic electrodes through 1MΩ resistors to limit discharge current.

o Patient contact points:

o Operator panels:

3. Electrical Fast Transients/Bursts (EFT/B) & Surge Immunity

• Key Requirements:

o Devices must not malfunction (e.g., infusion pump stops) or lose data (e.g., distorted waveforms on monitors) under interference.

• Protection Design:

o Add common-mode chokes (e.g., WE 744 series) and isolation ICs (e.g., ADI iCoupler) to RS-232/485 interfaces.

o Implement three-stage protection (GDT + MOV + TVS), with MOVs rated to survive 10 surge pulses per IEC 61000-4-5.

o Power port:

o Signal port:

4. Radiated RF Immunity (RS)

• Medical Environment Challenges:

o Devices must operate normally under 3V/m–10V/m (80MHz–2.5GHz) field strength, avoiding interference from Wi-Fi, mobile phones, etc.

• Solutions:

o Sensitive circuits (e.g., ECG amplifiers) should use differential signal transmission and be wrapped in copper foil shielding.

o Add error detection and recovery in software (e.g., CRC checks, watchdog reset).

Special Considerations for Medical Devices

1. Patient Safety Protection:

o Ensure all patient connection parts (e.g., lead wires, SpO₂ probes) meet BF/CF insulation requirements to prevent EMI-induced electric shock risk.

o Use medical-grade isolated power supplies (e.g., 5kV isolated DC-DC modules).

2. Signal Integrity:

o High-frequency medical equipment (e.g., MRI, ultrasound) must address signal distortion, avoiding excessive filtering that weakens useful signals.

3. Documentation & Risk Management:

o Rectification measures must be incorporated into risk management documentation per ISO 14971, assessing potential clinical impacts of EMC issues.

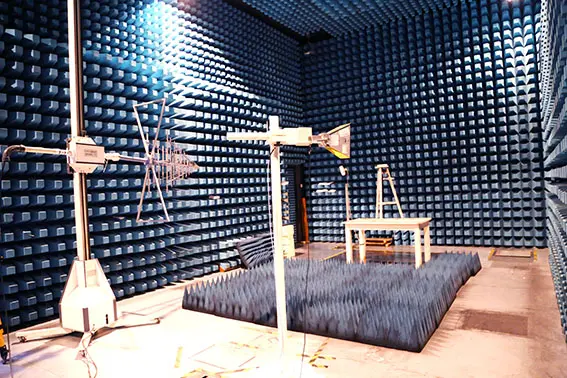

4. Simulated Test Environment:

o During testing, connect simulated patient loads (e.g., human impedance models), and monitor key parameters (e.g., heart rate, SpO₂ accuracy).

Typical Rectification Cases

• Case 1: ECG Signal in Monitor Affected by RF Interference

o Added ferrite beads to lead wires (nickel-zinc type to suppress high-frequency noise).

o Added EMI filter (cutoff frequency 1kHz) before amplifier circuit.

o Symptom: ECG waveform showed spikes during RS test.

o Rectification:

Ferrite beads added to lead wires (nickel-zinc material).

EMI filter (cutoff at 1kHz) added at amplifier input.

• Case 2: Infusion Pump Resets During EFT Test

o Added common-mode choke (100mH) and X-capacitor (0.1μF) to power input.

o Added 10nF capacitor to ground on MCU reset line.

o Symptom: MCU reset triggered by interference on power port.

o Rectification:

Common-mode choke (100mH) and X-capacitor (0.1μF) added at power input.

10nF capacitor added to ground on MCU reset line.

Email:hello@jjrlab.com

Write your message here and send it to us

Is EN 18031 Cybersecurity Compliance Mandatory?

Is EN 18031 Cybersecurity Compliance Mandatory?

How to Obtain EU CE Certification for Toys?

How to Obtain EU CE Certification for Toys?

How to get CE Certification for Electronic Electri

How to get CE Certification for Electronic Electri

ISO 10993-23 Irritation Testing

ISO 10993-23 Irritation Testing

Guide to Compliance Certification for IVD Devices

Guide to Compliance Certification for IVD Devices

Biocompatibility Testing for Passive Medical Devic

Biocompatibility Testing for Passive Medical Devic

Medical Mask Compliance Testing for EU & US Ma

Medical Mask Compliance Testing for EU & US Ma

Medical Device EMC Rectification Services

Medical Device EMC Rectification Services

Leave us a message

24-hour online customer service at any time to respond, so that you worry!