IEC EN 60601 Electrical Safety Testing

For medical devices to be exported to the EU market, CE certification is requiRED, which includes emc testing. Similarly, exporting to the US market necessitates completing emc tests for FDA certification. Submitting medical devices to the FDA under 510(k) or Premarket Approval (PMA) requires a series of extensive EMC tests, commonly referred to as iec 60601-1-2. These tests ensure that your medical device complies with the emission and immunity standards necessary for selling equipment in both the EU and the US.

What is IEC-60601-1-2?

IEC 60601 is a series of general standards established to define the safety and essential performance of medical electrical equipment. Within the general standards, there are specific subsidiary standards that require testing based on your device specifications. IEC-60601-1-2 is a subsidiary standard that mandates EMC testing on any electronic medical equipment. As part of the FDA submission, you will need a recognized laboratory to conduct the IEC-60601-1-2 tests.

What types of tests are required by IEC-60601-1-2?

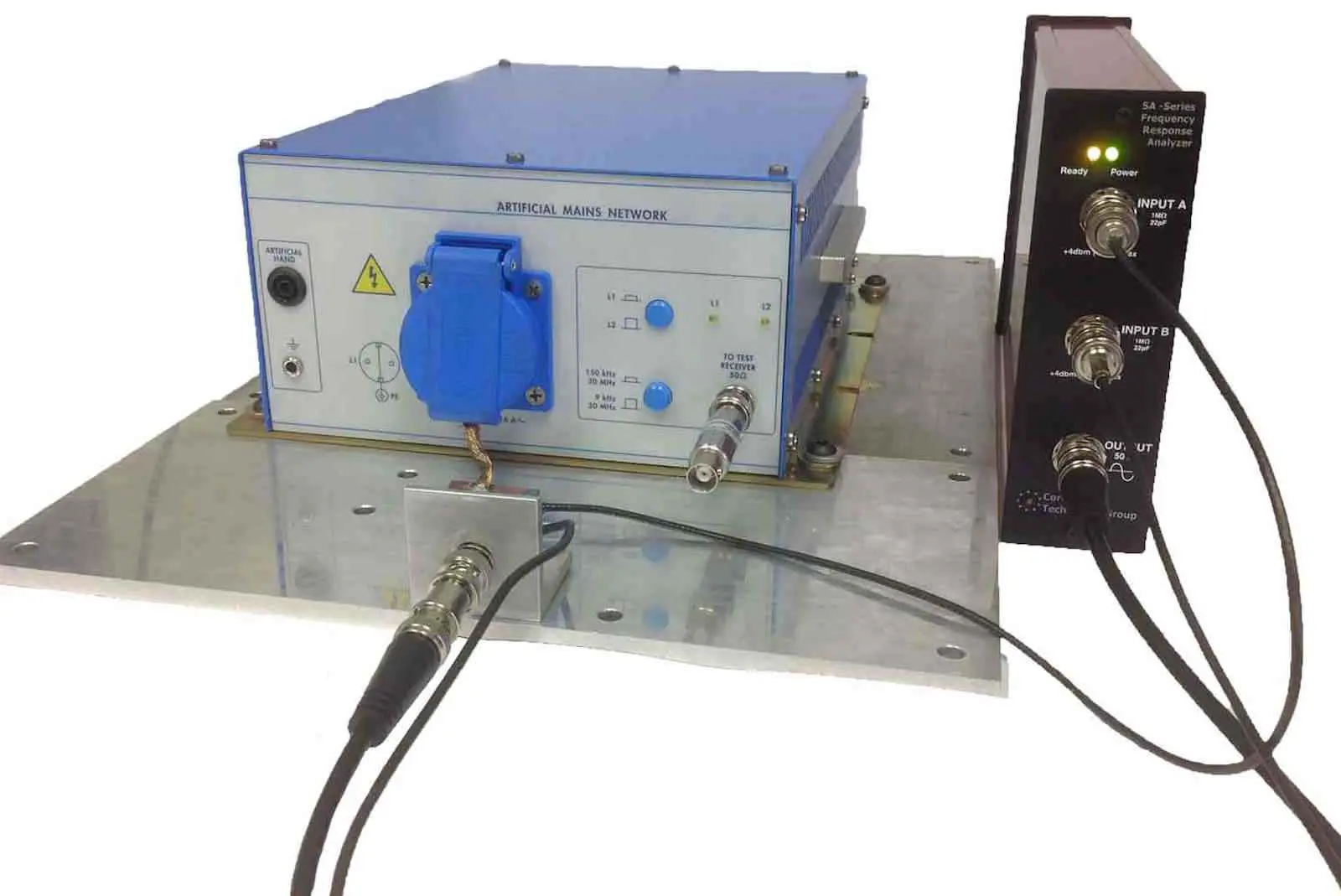

Conducted Emissions

Ensures no EMI is conducted back into the AC power supply.

We need to confirm that your medical device does not transmit EMI back into the AC power supply beyond CISPR 11 limits.

Radiated Emissions

Measures the amount of EMI emitted by the device.

Most modern electronic devices with MICrocontrollers generate low levels of EMI, which radiates into free space. CISPR 11 defines these radiation levels, and we measure your medical device to ensure it meets the limits.

Electrostatic Discharge (ESD)

Tests with simULated high-voltage ESD equipment.

ESD is a sudden flow of electricity that can cause high-voltage sparks. We use handheld devices to simulate these ESD events and test your equipment to ensure it can handle ESD within the limits of IEC-61000-4-2.

Radiated RF Immunity

We scan and inject RF noise into your device.

IEC-61000-4-3 tests involve transmitting various RF signals in a semi-anechoic chamber. IEC-61000-4-6 is a similar test where RF signals are directly connected to your product through cables. These tests ensure that your medical device does not malfunction in the presence of other RF signals.

Electrical Fast Transient/Burst

Evaluates your device’s response to rapid changes in input power.

IEC 61000-4-4 measures your product’s resilience to fast repetitive bursts. Conversely, IEC 61000-4-11 assesses the product's resistance to rapid voltage dips and interruptions. Lastly, IEC 61000-4-5 applies constant high-power surges to ensure your device can handle such events.

Magnetic Field Immunity

Tests if your device can handle magnetic fields.

We simulate high-power magnetic fields and apply them to your medical device as per IEC-61000-4-8. We evaluate your device to ensure it can function properly in the presence of magnetic fields.

We can complete the IEC-60601-1-2 testing for your medical device within 3 weeks. For more details, consult with JJR engineers!

What if my device doesn’t pass? Can you provide rectifications?

Besides EMC testing, our experienced staff has extensive backgrounds in medical device design and EMC remediation. We can assist in identifying problematic areas in your design and implement cost-effective solutions to expedite retesting and accelerate your product’s time to market.

Medical Device testing/IEC 60601-1-2 FAQs:

1. How does routine EMC testing for consumer products differ from medical device testing?

Medical devices undergo similar tests to fcc part 15 Class B devices, where CISPR 11 measures radiated emissions and checks conducted emissions back to the AC power supply. Additional tests for medical devices include ESD, RF immunity, and electrical pulses/surges/dips, which are not typical for FCC Part 15 devices, posing challenges for many designers.

2. What is the most common issue you encounter?

Without a doubt, most medical devices face issues with IEC-61000-4-2 (simulated ESD Testing). Isolating ESD from microcontrollers and other sensitive integrated circuits can be very challenging, often causing failures in this part of the testing.

3. How can we pre-test our device?

Many clients contact us for pre-testing their designs. We offer comprehensive pre-testing at 50% of the final testing cost to identify any system issues early before finalizing the product casing and PCB layout. While compliance is typically the last step, we encourage early engagement for pre-testing to be beneficial for designers.

4. Which IEC 60601-1-2 standards do you test?

We currently conduct all medical testing in accordance with IEC 60601-1-2:2014, 4th edition, published in February 2014. The FDA presently recognizes only IEC 60601-1-2:2014, 4th edition.

5. What do I need to provide for testing?

Depending on your device, we will need two production-quality samples. You must provide the final power supply, product manual, and written operating instructions. We will work with your design team to determine if any firmware changes are needed for testing.

6. What if I don’t pass?

Don't worry; over 50% of designs won't pass on the first try. The good news is that you chose to work with us. Typically, testing labs charge you for lab time. If you fail, they charge a hefty retest fee. Working with us, it's cheap to retest your product (there will be additional fees if the project is complex and exceeds the free retest time).

7. How long does the IEC 60601-1-2 testing process take?

Medical device testing can be conducted relatively quickly. From the receipt of your device, an IEC 60601-1-2 testing project usually takes about 3 weeks. The China JJR laboratory is an IEC 17025 accredited lab providing the relevant testing.

Email:hello@jjrlab.com

Write your message here and send it to us

IEC 60529 IP Rating Ingress Protection Standard

IEC 60529 IP Rating Ingress Protection Standard

IEC 60601-1 Medical Electrical Equipment Basic Saf

IEC 60601-1 Medical Electrical Equipment Basic Saf

European Authorized Representative Medical Devices

European Authorized Representative Medical Devices

EU Waste Electrical and Electronic Equipment Direc

EU Waste Electrical and Electronic Equipment Direc

How to Get CE Approval

How to Get CE Approval

Accelerated Ageing Test

Accelerated Ageing Test

IP Ingress Protection Testing

IP Ingress Protection Testing

How Does a Product Get an Energy Star Label

How Does a Product Get an Energy Star Label

Leave us a message

24-hour online customer service at any time to respond, so that you worry!