How to Get a CE Mark for a Medical Device?

Pathways to Obtain a CE Mark

The pathway to obtain the CE mark license can essentially be divided into two approaches: self-declaration (Declaration of Conformity, DOC) and certification by an EU-designated body. For low-risk products, manufacturers can self-certify through a declaration of conformity. Once the manufacturer determines that their product meets all the requirements of the relevant EU directives, the product can bear the CE mark. Therefore, for these types of products, the use of the CE mark does not require authorization and certification from a third party; the CE mark is a self-declaration or quality commitment from the manufacturer.

The EU classifies medical devices into four categories: Class I, Class IIa, Class IIb, and Class III.

Class I products can use the CE mark through self-declaration. This means that manufacturers prepare a technical file for the product and either test the product against the relevant EN standards themselves or commission a competent laboratory to conduct the tests.

For higher-risk Class IIa, Class IIb, and Class III products, validation must be performed by an EU-designated verification body, obtaining a Type Examination Certificate or CE Attestation from the designated body.

EU regulations state that the prerequisite for obtaining CE certification for these categories of products is that the manufacturing facility must pass ISO 13485 quality management system certification and obtain an ISO 13485 certificate. The certifying body must be an EU-accredited certifying organization, allowing the certified company to use the CE mark.

Process for Enterprises to Apply for CE certification

Basic Conditions for Enterprises Applying for CE Certification:**

1. The enterprise must have a valid business license (legal entity).

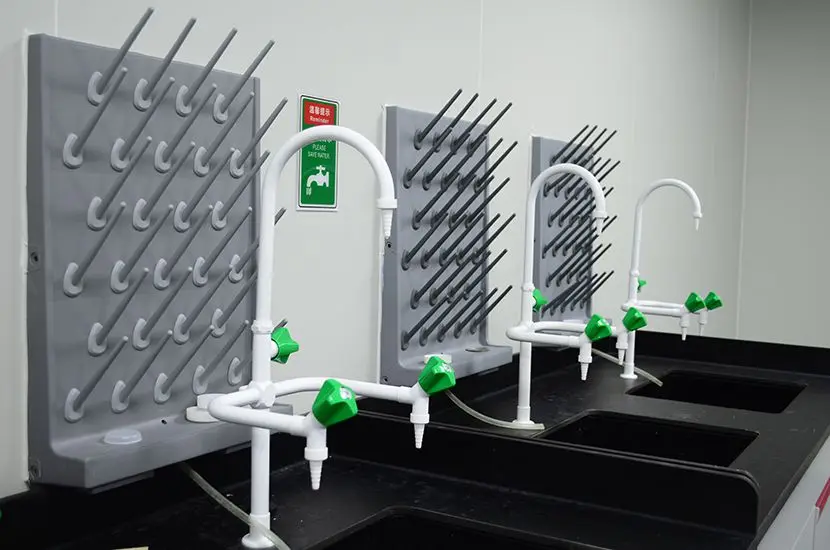

2. The enterprise should have a fixed place for production and operations.

3. The enterprise has established quality management system documents according to ISO 9001 and ISO 13485 standards and related EU regulations and has implemented them.

4. Prototypes have been produced under the control of quality management system documents according to applicable international standards and related EU standards.

5. Applicable standards have been identified and a list has been prepared (harmonized standards, international standards, partially applicable standards).

6. A product description report has been prepared (including product composition/specifications and parameters).

7. Technical documentation should include: production flow charts, assembly diagrams, insulation diagrams, electrical diagrams, a list of critical components, labels, instructions, and biological evaluation (ISO 10993).

8. Risk analysis has been conducted on the product according to ISO 14971 standards, and a risk analysis report has been prepared.

9. Relevant clinical literature has been collected, and a draft clinical investigation has been prepared according to the requirements of MDD 93/42/EEC, Annex 10.

10. A self-assessment has been conducted according to the basic requirements in Annex I of MDD 93/42/EEC, with corrective measures taken.

11. The enterprise has an EU authorized representative and has signed an authorization agreement.

12. The enterprise commits to complying with relevant EU laws, regulations, and other requirements, pledging to adhere to the certification regulations and assume legal responsibilities related to certification.

13. The enterprise commits to using the certification certificate and mark as prescribed after certification and to accepting supervision as required.

Medical Device CE Certification Process

1. The enterprise selects and confirms an EU-designated notified body (certifying body).

2. Submits a CE certification application.

3. The certifying body conducts an on-site inspection, classifies the product, and confirms the certification model.

4. Signs a certification contract.

5. The certifying body implements ISO 9001 + ISO 13485 quality management system certification.

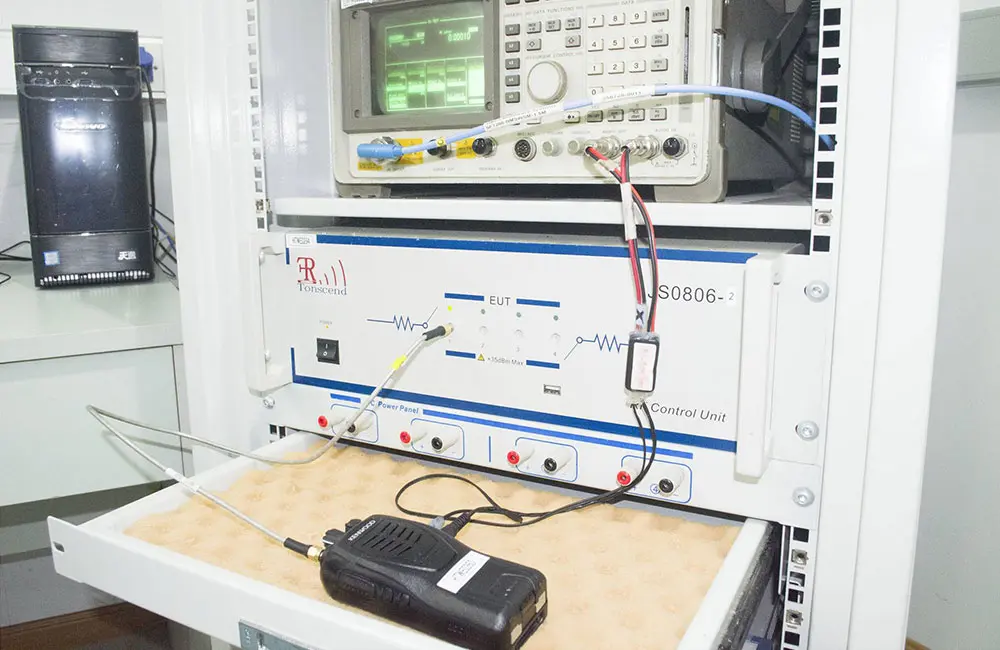

6. The enterprise sends prototypes to the authorized testing organization of the certifying body for product safety testing.

7. Determines the method for clinical evaluation and the final clinical evaluation report.

8. Submits technical documentation.

9. The certifying body reviews the technical documentation.

10. The certifying body completes the review and determines whether to recommend issuing a certificate.

11. Issues the CE certification certificate.

12. Conducts regular audits annually.

Technical Documentation Related to CE Certification for Medical Devices

"Technical documentation" is a very important aspect of the EU medical device directives, requiring enterprises to prepare sufficient technical data and proof for inspection by regulatory authorities or for use in litigation disputes. Technical documents must be retained for inspection by the regulatory authorities. The responsibility for retaining technical documentation begins when the product is placed on the EU market, regardless of where the products are manufactured, and this responsibility lies with the manufacturer or their authorized representative established within the EU. The medical device directive 93/42/EEC requires that "technical documentation" may include the following items:

1. The company’s quality manual and procedural documents.

2. Company profile and contact information for the European representative.

3. CE Declaration of Conformity (or self-declaration; if the product is used in conjunction with other devices, there should be proof of overall conformity to basic requirements).

1. A brief description of the product name, classification, and referenced standard clauses.

2. An overview of the product (including type and intended use): product history, technical performance parameters, a list of attachments, components, and other devices used with the product, product illustrations and samples, raw materials and suppliers used in the product.

3. The harmonized standards/other standards applicable to the product.

4. Conclusions from the risk analysis and preventive measures (EN 1441 product service hazard analysis report).

5. Production quality control: product information and control documents (including product production process flowcharts), descriptions of sterilization methods and confirmations, sterilization validations, product quality control measures, descriptions of product stability and shelf life.

6. Packaging and labeling: packaging material descriptions, labels, instructions for use.

7. Technical evaluation: product inspection reports and related literature, technical summaries, and authoritative opinions.

8. Potential risk assessment: reports on potential risk testing of the product and related literature, summaries of potential risks, and authoritative opinions.

9. Clinical evaluation: product clinical testing reports and related literature, an overview of clinical use, and authoritative opinions. Clinical evaluation includes clinical studies (including: physical performance, biochemical, pharmacological, toxicological studies, efficacy testing, sterilization compliance verification, drug compatibility, etc.); biocompatibility testing (A) EN 30993 Part 1 requirements: cytotoxicity, photosensitivity, irritation - intradermal reaction, acute systemic toxicity, pyrogenicity, subacute toxicity, genetic toxicity, hemolytic compatibility; B) supporting tests: chronic toxicity, carcinogenicity, regenerative/growth toxicity, biological degradation). Clinical data (requires clinical studies or descriptions of clinical studies).

4. Packaging compliance certificates (EN 868).

5. Labels, instructions for use (EN 980, EN 1041).

6. Conclusions (acceptance of design documentation, statement of benefits versus risks).

7. Post-certification surveillance of CE certification.

After an enterprise obtains certification, the certifying body conducts an annual surveillance audit starting from the second year, with a three-year cycle. In the fourth year, a re-evaluation is conducted, which is the same as the initial certification audit. If, during the audit cycle, new international standards for the certified product are released or new EU directives are issued, the certifying body should promptly notify the enterprise to evaluate the product and, if testing is involved, require the enterprise to promptly go to the designated testing organization for evaluation, focusing on these in the next year's surveillance audit.

Email:hello@jjrlab.com

Write your message here and send it to us

Australia RCM LOGO Certification

Australia RCM LOGO Certification

ANATEL Certification Process in Brazil

ANATEL Certification Process in Brazil

Faucet European Standard EN 817 Testing

Faucet European Standard EN 817 Testing

ISO 17025 Laboratory Test Report

ISO 17025 Laboratory Test Report

Temu Requires UN 38.3 Certification

Temu Requires UN 38.3 Certification

What is the Amazon ASTM F2057 Test Report?

What is the Amazon ASTM F2057 Test Report?

How to get the Amazon SOR/2016-175 Test Report?

How to get the Amazon SOR/2016-175 Test Report?

Amazon Electronic Product UL Test Report

Amazon Electronic Product UL Test Report

Leave us a message

24-hour online customer service at any time to respond, so that you worry!