How Much Does UL 4200A Cost?

ul4200 certification costs vary depending on the product, testing requirements, and the laboratory. Generally, ul certification costs include application fees, testing fees, audit fees, and more. The specific cost ranges from $450-$720, depending on the specifications of the button cell battery.

UL Logo

What is UL4200 certification?

UL4200 certification is a testing standard conducted by the American UL certification organization for button cell batteries. It primarily evaluates the safety performance and child-resistant capabilities of button cell batteries. This certification focuses on the safety of batteries in unexpected situations to REDuce the risk of injury to users. Testing includes various indicators such as short circuit, overcharging, overdischarging, vibration, high temperature, low temperature, etc., to ensure that the batteries do not explode or catch fire during normal use.

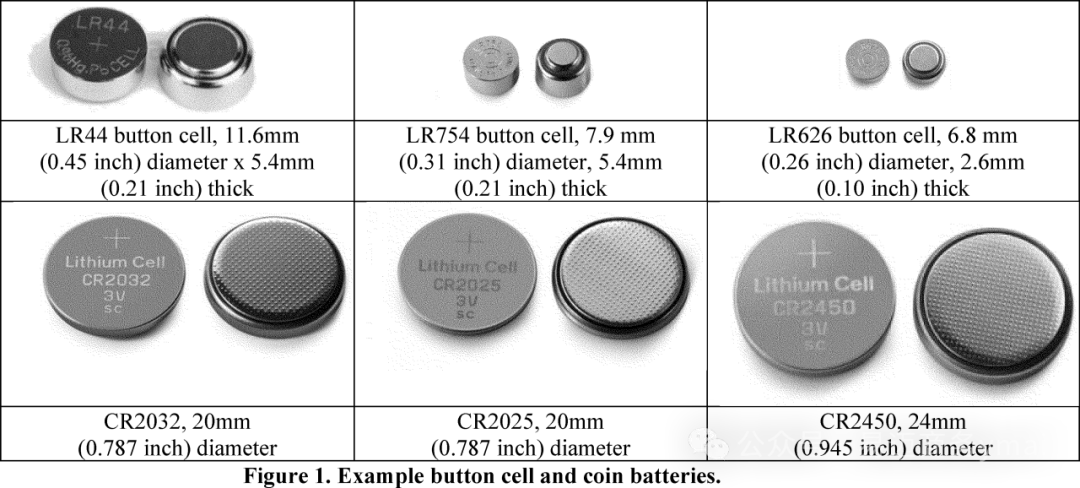

Button Cell Batteries

If the product test results meet the requirements of the UL4200 standard, UL certification can be obtained. This helps to enhance the safety and competitiveness of the product. It's important to note that UL certification is voluntary and not a mandatory regulatory requirement. Additionally, the UL4200 standard may be updated over time with technological developments, so compliance with the latest standards is necessary during certification. In summary, UL4200 certification is an important certification for the safety performance of button cell batteries, ensuring high safety and stability during use to protect user safety and ensure the normal operation of devices.

Where can UL4200 certification be obtained?

UL4200 certification can be obtained at UL-accredited third-party laboratories. You can find accredited laboratories through the UL official website and submit test applications to them. The laboratory will conduct tests according to the requirements of the UL4200 standard and provide test reports. If the test results meet the requirements of the UL4200 standard, the laboratory will provide you with UL certification marks that you can use on your products to demonstrate compliance with the UL4200 standard.

Consulting for ul4200a certification

When selecting a laboratory, it's important to ensure that it has relevant qualifications and experience to ensure the accuracy and reliability of test results. Additionally, you need to comply with ul testing standards and requirements to ensure that the testing process meets the requirements of the UL4200 standard.

UL4200 certification is significant for enhancing the safety and competitiveness of products, especially those intended for sale in international markets. Through UL4200 certification, you can demonstrate to consumers that your products meet international safety standards, thereby increasing consumer trust and willingness to purchase.

UL4200 certification costs?

The general cost to apply for button battery 4200A certification is about US$400, the cycle is 7 to 8 working days, and no factory audit is required.

UL4200 certification period

7 to 8 working days

UL4200 certification process

1. Send samples to JJR testing laboratory

2. The laboratory receives the samples and conducts tests according to the UL4200 standard test items;

3. Testing completed, engineer writes a report;

4. The organization issues a factory audit task to go to the customer's factory for audit

5. Audit passed, laboratory issues UL4200A certificate

6. Post-maintenance, and cooperate with quarterly factory audits.

What is UL certification factory inspection?

UL certification factory inspection is an important part of the ul certification process, mainly evaluating and auditing production factories to ensure they have the capability and quality management system to produce products that meet UL standards. Inspection covers various aspects of the factory's production facilities, equipment, processes, personnel, and quality management systems.

In UL certification factory inspection, UL certification organizations will dispatch professional auditors to conduct on-site audits of production factories. Auditors will carefully observe and evaluate the factory's production site to check whether the factory has the capability and conditions to produce products that meet UL standards. Additionally, auditors will evaluate the factory's quality management system, including quality control, inspection, and testing, to ensure that the factory can consistently and stably produce products that meet UL standards.

In addition to evaluating the factory's production capabilities and quality management systems, UL certification factory inspection also includes testing and inspection of products. Auditors will conduct sampling tests on products produced by the factory to verify whether they meet UL standard requirements. If the test results of the products do not meet the standard requirements, the factory needs to make corresponding improvements and revisions until the products meet the standard requirements.

Through UL certification factory inspection, factories can obtain recognition from UL certification organizations, proving that their products meet UL standards. This helps to enhance the market competitiveness and product reputation of the factory, while also providing consumers with safer and more reliable product choices.

It's important to note that UL certification factory inspection is a periodic process. Factories need to continuously maintain the compliance of their production capabilities and quality management systems to ensure continued recognition from UL certification organizations. Additionally, factories need to cooperate with UL certification organizations' supervision and audit work, providing relevant materials and information in a timely manner to ensure the effectiveness and reliability of UL certification.

```

Email:hello@jjrlab.com

Write your message here and send it to us

How Do You Get a CE Mark

How Do You Get a CE Mark

IEC 60529 IP Rating Ingress Protection Standard

IEC 60529 IP Rating Ingress Protection Standard

IEC 60601-1 Medical Electrical Equipment Basic Saf

IEC 60601-1 Medical Electrical Equipment Basic Saf

European Authorized Representative Medical Devices

European Authorized Representative Medical Devices

EU Waste Electrical and Electronic Equipment Direc

EU Waste Electrical and Electronic Equipment Direc

How to Get CE Approval

How to Get CE Approval

Accelerated Ageing Test

Accelerated Ageing Test

IP Ingress Protection Testing

IP Ingress Protection Testing

Leave us a message

24-hour online customer service at any time to respond, so that you worry!