GB 9706.1-2020 Medical Device Safety Testing Items

1. Structural Inspection and Testing: Testing whether the structure of the equipment complies with the standard requirements, including the connection, fixation, and protection of each component.

2. Power Supply Voltage Adaptability: Testing whether the equipment can operate normally under the specified power supply voltage range.

3. Insulation Resistance: Testing whether the insulation material of the equipment meets the standard resistance requirements to avoid current leakage and electrical shock hazards.

4. Leakage Current: Testing whether the current of the equipment's casing or casing components in normal operation meets the standard to ensure user safety.

5. Dielectric Strength (Voltage Withstand Test): Testing whether the insulation material of the equipment can remain stable without breakdown under the specified voltage and time.

6. Abnormal Operation and Fault Conditions: Testing whether the equipment can shut down safely and notify the operator for repair under abnormal working conditions or faults.

7. Mechanical Strength: Testing whether the equipment structure can withstand the specified external force to avoid safety hazards caused by mechanical damage.

8. Stability: Testing whether the equipment can remain stable during normal operation without noticeable shaking or shifting.

9. Liquid Ingress: Testing whether the equipment can prevent liquid from entering the interior to avoid issues such as short circuits.

10. Cleaning and Disinfection: Testing whether the equipment can be easily cleaned and disinfected to maintain hygiene.

11. Temperature and Humidity: Testing whether the equipment can operate normally within the specified temperature and humidity range to avoid safety hazards caused by unsuitable conditions.

12. Grounding Test: Testing whether the grounding of the equipment meets the standard to avoid safety hazards caused by electric leakage.

Email:hello@jjrlab.com

Write your message here and send it to us

Wireless Microphone Export Certification

Wireless Microphone Export Certification

Audio-Visual Products SNI Certification in Indones

Audio-Visual Products SNI Certification in Indones

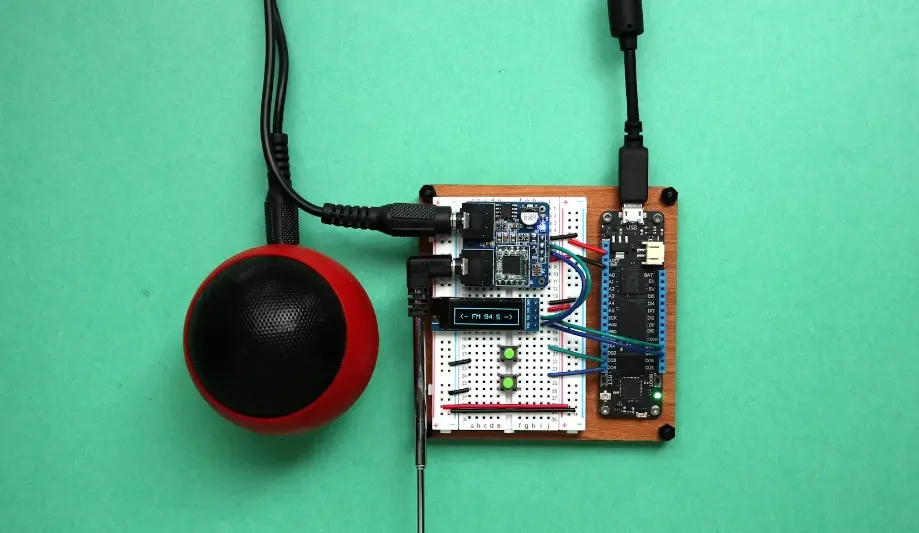

FCC-ID: Still Needed if Module is Certified?

FCC-ID: Still Needed if Module is Certified?

FCC Certification Fees for Handheld Fans

FCC Certification Fees for Handheld Fans

FCC Certification Testing for Smart Lighting Produ

FCC Certification Testing for Smart Lighting Produ

What is the ETSI EN 303 645 Testing Standard?

What is the ETSI EN 303 645 Testing Standard?

UL Compliance and ETL Certification for LED Lighti

UL Compliance and ETL Certification for LED Lighti

What is the IEC 60598 Standard?

What is the IEC 60598 Standard?

Leave us a message

24-hour online customer service at any time to respond, so that you worry!