FCC Certification Tests for Power Supplies

As an essential component of electronic devices, the safety and compliance of power supplies are crucial for the overall performance of the equipment. In the global market, the entry threshold for the US market is relatively high, with fcc certification being one of the necessary conditions for power supplies to enter the US market. So, what tests are included in the fcc certification for power supplies? This article will provide a detailed explanation from mULtiple aspects. (JJRLAB, located in China, can save you 30% on fcc certification testing costs)

1. Electromagnetic Compatibility Testing

Electromagnetic compatibility testing is an important part of FCC certification for power supplies. This test aims to ensure that the power supply will not interfere with other devices during operation, and that it will not be affected by other devices. The test content includes conducted disturbances, radiated disturbances, and other aspects. By evaluating the electromagnetic radiation and conduction performance of the power supply under various working conditions, it can be determined whether it meets the FCC's electromagnetic compatibility standards.

2. Conducted Disturbance testing

Conducted disturbance testing is a critical part of FCC certification for power supplies. Conducted disturbance refers to the electromagnetic interference injected into the power grid through power lines or other conductors during the operation of the power supply. This test measures the level of conducted disturbances from the power supply under normal working conditions to determine if it meets the FCC's limits on conducted disturbances. High levels of conducted disturbances can interfere with other electrical equipment and even affect the stability of the entire power grid.

3. Radiated Disturbance Testing

Radiated disturbance testing is an indispensable part of FCC certification for power supplies. Radiated disturbances refer to the radio wave radiation generated by the power supply during operation, which may interfere with nearby wireless communication devices. Radiated disturbance testing measures the radiation levels of the power supply across various frequency bands to ensure that it meets the FCC's limits on radiated disturbances. This test is crucial for maintaining a clean electromagnetic environment and ensuring the normal operation of wireless communication devices.

4. Other Testing Items

In addition to the above electromagnetic compatibility, conducted disturbance, and radiated disturbance tests, FCC certification for power supplies may also include other testing items, such as safety performance testing and energy efficiency testing. These tests aim to comprehensively evaluate the performance and quality of the power supply to ensure its safety, reliability, and energy efficiency during use.

In summary, FCC certification testing for power supplies covers multiple aspects, including electromagnetic compatibility, conducted disturbances, and radiated disturbances. These tests provide a comprehensive assessment of the electromagnetic and safety performance of the power supply to ensure that it meets the entry standards of the US market. For manufacturers and exporters of power supplies, understanding and mastering the requirements and processes of these tests will help enhance product competitiveness and facilitate smooth entry into the US market.

When conducting FCC certification testing for power supplies, it is recommended that companies choose certification bodies with rich experience and professional qualifications to ensure the accuracy and reliability of the test results. Additionally, companies should strengthen the research and innovation of power supplies to continuously improve product performance and quality to meet the increasingly stringent demands of the US market.

Email:hello@jjrlab.com

Write your message here and send it to us

Weee authorised representative germany

Weee authorised representative germany

Where to Apply for 2026 Air & Sea Transport Ce

Where to Apply for 2026 Air & Sea Transport Ce

Guide to IEC Test Reports for Lighting Exports

Guide to IEC Test Reports for Lighting Exports

IEC/EN 62471 and IEC/EN 62778 (Photobiological Saf

IEC/EN 62471 and IEC/EN 62778 (Photobiological Saf

How to get IEC 62471/EN 62471 Test Reports?

How to get IEC 62471/EN 62471 Test Reports?

IEC 62471 Photobiological Safety Certification

IEC 62471 Photobiological Safety Certification

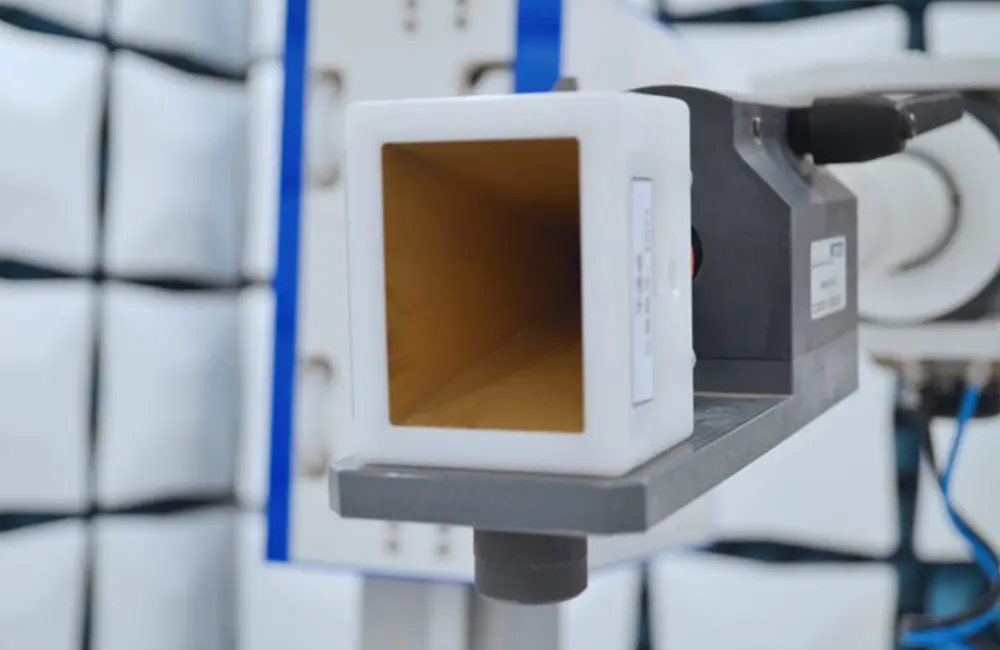

EMC Item – Introduction to Radiated Emission Test

EMC Item – Introduction to Radiated Emission Test

IEC 62471 Photobiological Safety of Lamps and Lamp

IEC 62471 Photobiological Safety of Lamps and Lamp

Leave us a message

24-hour online customer service at any time to respond, so that you worry!