EU CE Certification for Machinery Directive (MD)

The CE certification under the Machinery Directive (MD) is an EU regULation focused on the safety and health requirements of machinery products, aiming to ensure the safety and health of machinery and to prevent potential hazards to users and those nearby. This directive sets out essential health and safety requirements, covering the entire field of mechanical engineering, and is a highly important certification directive for industrial society.

Scope of Machinery Certification

1. Machinery (covering most machines used for production and processing)

2. Interchangeable equipment

3. Safety components

4. Lifting accessories

5. Chains, ropes, and webs

6. Removable mechanical transmission devices

7. Incomplete machinery

Safety Principles for Machinery

1. Eliminating and REDucing risks from the design and manufacturing perspective as much as possible: Safety factors should be considered during the design phase by optimizing the design and using safe materials to reduce potential safety risks.

2. Taking necessary protective measures for risks that cannot be eliminated: For risks that cannot be avoided through design, physical barriers, safety devices, and other measures should be implemented to ensure the operator’s safety when using the machinery.

3. Informing users of risks caused by deficiencies in protective measures through labels, and specifying whether special training and personal protective equipment are required: This ensures that operators are aware of the potential risks and know how to use the machinery safely and correctly.

Safety Assessment of Machinery

The safety assessment of machinery mainly involves two parts: mechanical and electrical.

- The mechanical safety assessment is primarily based on the EN ISO 12100:2010 standard, which provides general principles for the design of machinery safety, including risk assessment and risk reduction methods.

- For specific machinery products, such as air compressors and earth-moving machinery, there are dedicated safety requirement standards: EN 1012-1:2010 and EN 474-1:2006+A4:2013/AC:2014. These standards specify the safety performance requirements and testing methods for machinery in detail.

- The electrical safety assessment is primarily based on the EN 60204-1:2006/AC:2010 standard, which sets out the general technical conditions for electrical equipment, including relevant IEC standard requirements, EMC requirements, and power cut-off device requirements. Additionally, it mentions the need for protective measures against direct and indirect contact with electrical components, and if the control circuit is powered by AC, a transformer with separate windings is required, along with other specific requirements.

Certification Models for Machinery

In the directive, machinery is classified into two major categories: general machinery and dangerous machinery. Seventeen categories of dangerous machinery are detailed in Annex IV of the directive, with higher safety assessment requirements for dangerous machinery.

- General machinery:

- Mode A (Internal production control, EC Declaration of Conformity, Annex VIII)

- Dangerous machinery (produced according to harmonized standards):

- Mode A (Internal production control, Annex VIII)

- Mode B (EC type examination + internal production control assessment, Annex IX + Annex VIII, point 3)

- Mode H (Full quality assurance system, Annex X)

- Dangerous machinery (not produced or partially produced according to harmonized standards, or without harmonized standards):

- Mode B (EC type examination + internal production control assessment, Annex IX + Annex VIII, point 3)

- Mode H (Full quality assurance system, Annex X)

Documents Required for Machinery Certification

1. Product name, model, and address of applicant/manufacturer

2. Product model and detailed technical parameters

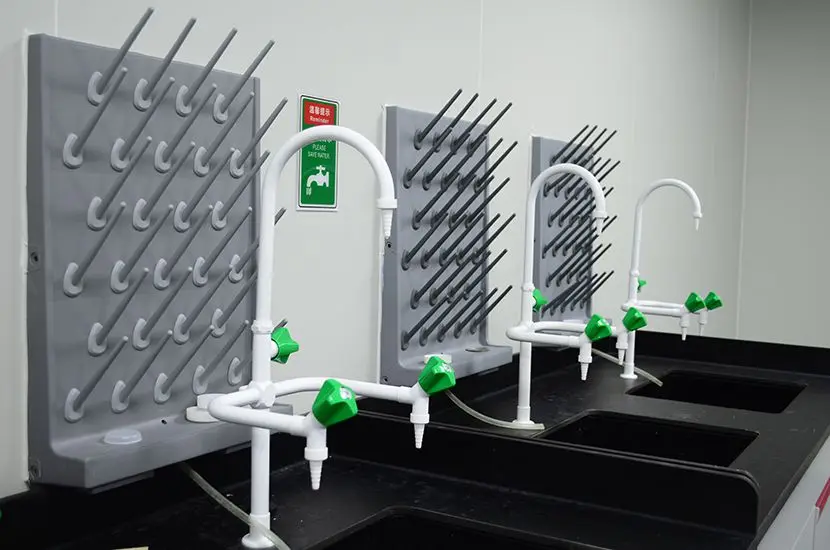

3. Detailed images of components and overall structure

4. Electrical schematic (for electrical products)

5. Mechanical assembly drawings and key component diagrams

6. Nameplate (font, ce mark)

7. Product user manual, installation, and maintenance instructions (in English)

8. Parts list (product name, manufacturer)

Email:hello@jjrlab.com

Write your message here and send it to us

Weee authorised representative germany

Weee authorised representative germany

Where to Apply for 2026 Air & Sea Transport Ce

Where to Apply for 2026 Air & Sea Transport Ce

Guide to IEC Test Reports for Lighting Exports

Guide to IEC Test Reports for Lighting Exports

IEC/EN 62471 and IEC/EN 62778 (Photobiological Saf

IEC/EN 62471 and IEC/EN 62778 (Photobiological Saf

How to get IEC 62471/EN 62471 Test Reports?

How to get IEC 62471/EN 62471 Test Reports?

IEC 62471 Photobiological Safety Certification

IEC 62471 Photobiological Safety Certification

EMC Item – Introduction to Radiated Emission Test

EMC Item – Introduction to Radiated Emission Test

IEC 62471 Photobiological Safety of Lamps and Lamp

IEC 62471 Photobiological Safety of Lamps and Lamp

Leave us a message

24-hour online customer service at any time to respond, so that you worry!