Update: EN IEC 60335-2-9 Cooking Appliances Test Standard

In the new consumption era where the Internet is booming, small household appliances are deeply loved by foreign users due to their advantages such as small size, exquisite appearance and unique functions, and portable cooking utensils are especially popular products.

60335-2-9 New version released

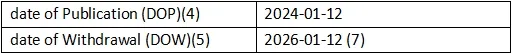

In March 2023, the European Technical Committee issued the new standard EN IEC 60335-2-9:2023+A11:2023. Its permitted use date is tentatively set as 2024-01-12, and the mandatory implementation date is tentatively set as 2026-01-12. In CE-lvd certification, you still need to wait for the official implementation date given in the EU official announcement (OJ), and the OJ document shall prevail.

EN IEC 60335-2-9:2023 is a synchronous update based on the international standard IEC 60335-2-9:2019 without any modification; however, the new amendment EN IEC 60335-2-9:2023/A11:2023 makes supplementary deviation requirements. The important changes are briefly described below.

Main additional requirements

Logo and nameplate:

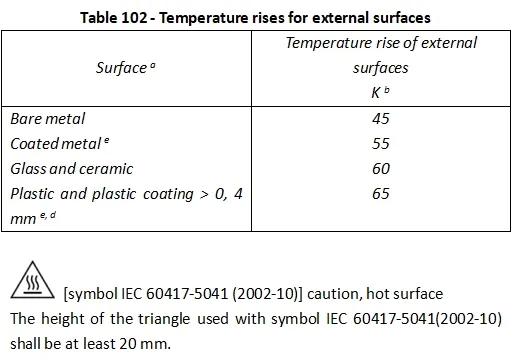

The scope of use of the hot surface warning label and warning statement is applicable to the following two situations:

⑴External surfaces evaluated using footnote b of Table 102 (where double the temperature rise limit is used) ;

⑵External surfaces evaluated using Table 102+40K (case of single temperature rise limit +40K) .

Surface temperature rise:

If the total area of the vents and the surfaces within 25 mm of the vents does not exceed 20% of the total accessible surface area , the vents and the surfaces within 25 mm of the vents are exempted from the unlimited temperature rise requirement and can be tested;

If the total area of the ventilation opening and the surface within 25mm around it exceeds 20% of the total accessible surface area , the excess surface within 25mm around the ventilation opening shall comply with the temperature limit requirements in Table 102 .

The total accessible surface area of the enclosure is calculated as follows: The area of the accessible surface of the appliance in accordance with EN 61032 Type B test means minus the following area (i.e. the total accessible surface area of the enclosure) :

⑴External thermally functional surfaces;

⑵handles, knobs, controls and similar devices;

⑶The bottom surface cannot be reached by the test probe 41 of EN 61032 .

However, vents and surfaces within 25 mm of the area covered above are not taken into account in the calculation of the 20% accessible enclosure surface.

During the test, EN 61032 Type B test means that the temperature rise of the accessible external front, top and rear surfaces shall not exceed the values specified in Table 102 + 40K , and the temperature rise of other external surfaces shall not exceed the values specified in Table 102 , except for non-measurement surfaces.

2.1(11.101) Toaster surface temperature rise test:

Under normal working conditions, operate at rated power for 3 cycles; during which the temperature rise of the accessible surface shall not exceed that in Table 102;

The following surface temperature rises do not need to be measured:

-For top loading equipment, the surface is within 25 mm below the upper surface;

-The surface within 25mm outside the contour line of the thermal functional surface;

-The bottom surface that cannot be touched by the No. 41 probe is not more than 1N;

-Ventilation holes and surfaces within 25 mm, this area shall not exceed 20% of the total accessible surface area. Surfaces exceeding 20% must still meet the requirements of Table 102.

Toaster surface temperature rise test table 102 footnote b (double limit) only applies to the following surfaces:

-For top loading equipment, the surface is between 25mm - 50mm below the upper surface;

-The surface between 25mm and 50mm outside the contour line of the thermal functional surface;

-Surface between 25mm - 50mm around the ventilation holes.

2.1(11.101) Toaster surface temperature rise test:

Under normal working conditions, operate at rated power for 3 cycles; during which the temperature rise of the accessible surface shall not exceed that in Table 102;

The following surface temperature rises do not need to be measured:

-For top loading equipment, the surface is within 25 mm below the upper surface;

-The surface within 25mm outside the contour line of the thermal functional surface;

-The bottom surface that cannot be touched by the No. 41 probe is not more than 1N;

-Ventilation holes and surfaces within 25 mm, this area shall not exceed 20% of the total accessible surface area. Surfaces exceeding 20% must still meet the requirements of Table 102.

Toaster surface temperature rise test table 102 footnote b (double limit) only applies to the following surfaces:

-For top loading equipment, the surface is between 25mm - 50mm below the upper surface;

-The surface between 25mm and 50mm outside the contour line of the thermal functional surface;

-Surface between 25mm - 50mm around the ventilation holes.

2.2(11.102) Toaster oven, rotary grills, cookers Surface temperature rise test:

Under normal working conditions, rated power, all heating elements work simultaneously; during this period, the temperature rise of the accessible surface cannot exceed Table 102;

The following surface temperature rises do not need to be measured:

-Surface within 10mm of the edge of the door or drawer;

-The bottom surface that the No. 41 probe cannot touch must be pressed with a force not exceeding 1N.

-Cooker: When the upper burner is working, the surface within 25mm below the upper surface;

-For ventilation holes and surfaces within 25 mm, this area shall not exceed 20% of the total accessible surface area. Surfaces exceeding 20% must still meet the corresponding temperature rise requirements.

Oven, rotary grills, cookers Surface temperature rise test Table 102 footnote b applies only to the following surfaces:

-Surfaces between 10mm and 50mm from the inner edge of doors or drawers;

-The surface between 10mm and 50mm from the left/right/bottom outer edge of the door or drawer, or the surface between 25mm and 75mm from the top edge;

-Surface between 25mm - 50mm around the ventilation holes.

Result judgment:

-Except for the accessible surfaces that do not need to be measured, the temperature rise of the accessible front, top and back surfaces of Type B test shall not exceed Table 102+40K;

-The temperature rise of other external surfaces shall not exceed the limit values specified in Table 102.

2.3(11.103) Contact grills, waffle irons, radiant grills, raclette grills, barbecues, candy floss appliances and hot plates Surface temperature rise test:

Under normal working conditions, the rated power of electric heating and the rated voltage of electromagnetic furnaces; the temperature rise of the touchable surface during the period shall not exceed Table 102;

The following surface temperature rises do not need to be measured:

-The surface within 25mm of the outer contour of the thermal functional surface;

-The bottom surface that cannot be touched by the No. 41 probe is not more than 1N;

-lids and splash guards (not limited to the original Griddles range);

-Ventilation holes and surfaces within 25 mm, this area shall not exceed 20% of the total accessible surface area. Surfaces exceeding 20% must still meet the requirements of Table 102.

For contact grills, waffle irons, raclette grills, barbecues and radiant grills, footnote b to Table 102 applies to the entire product enclosure.

2.4(11.104) Breadmakers, pop-corn makers and food dehydrators Surface temperature rise test:

Under normal working conditions, the bread machine is rated voltage and the rest is rated power; during this period, the temperature rise of the accessible surface cannot exceed Table 102.

The following surface temperature rises do not need to be measured:

-The surface within 25mm of the lid edge;

-Surface within 25mm of the window and window edge;

-The bottom surface that cannot be touched by the No. 41 probe is not more than 1N;

-Ventilation holes and surfaces within 25 mm, this area shall not exceed 20% of the total accessible surface area. Surfaces exceeding 20% must still meet the requirements of Table 102.

2.5(11.105) Roasters surface temperature rise test:

Under normal working conditions, rated power; during which the temperature rise of the accessible surface shall not exceed that in Table 102;

The following surface temperature rises do not need to be measured:

-cover;

-The surface within 25mm of the lid edge;

-The bottom surface that cannot be touched by the No. 41 probe is not more than 1N;

-Ventilation holes and surfaces within 25 mm. This area shall not exceed 20% of the total accessible surface area. Surfaces exceeding 20% must still meet Table 102.

3.Simulate fault conditions:

The scope of the original 19.11.2 "The start-up of the heating element after the failure of the electronic component" has been narrowed down to toasters, which is consistent with the IEC standard.

4.structure:

22.Z101 For Toaster

Increase the bread pop-up height requirement: After the product completes the setting program, the bread depth in the slot cannot exceed 60mm (that is, the height of the bread rack from the top surface of the toaster is ≤60mm).

This requirement does not apply to the following situations:

-The temperature rise of the upper surface does not exceed the single limit;

-Products with sandwich grill attachment.

22.Z102 For raclette appliances

The position of the handle should be clearly identifiable by tactile means to avoid accidental contact with the hot surface of the appliance.

Email:hello@jjrlab.com

Write your message here and send it to us

Wireless Microphone Export Certification

Wireless Microphone Export Certification

Audio-Visual Products SNI Certification in Indones

Audio-Visual Products SNI Certification in Indones

FCC-ID: Still Needed if Module is Certified?

FCC-ID: Still Needed if Module is Certified?

FCC Certification Fees for Handheld Fans

FCC Certification Fees for Handheld Fans

FCC Certification Testing for Smart Lighting Produ

FCC Certification Testing for Smart Lighting Produ

What is the ETSI EN 303 645 Testing Standard?

What is the ETSI EN 303 645 Testing Standard?

UL Compliance and ETL Certification for LED Lighti

UL Compliance and ETL Certification for LED Lighti

What is the IEC 60598 Standard?

What is the IEC 60598 Standard?

Leave us a message

24-hour online customer service at any time to respond, so that you worry!