Electromagnetic Compatibility (EMC) Rectification Services

The services offered by China JJR Laboratory include: Electromagnetic Compatibility (EMC) testing, EMC solution optimization, EMC laboratory construction, safety (Safety) testing, and environmental reliability testing. Certification fields include: European CE, US FCC, FDA, China NMPA, CCC, model approval, network access certification, etc.

Three Key Elements of EMC Rectification

- Filtering: The main filtering components include ferrite beads, magnetic rings, and power filters. Ferrite beads, commonly called iron oxide, are made from iron, nickel, zinc, and other metal oxides. They provide filtering effects in frequency ranges below 200MHz. Compared to inductors, they have smaller distributed capacitance and better high-frequency characteristics. They are often used for power or signal filtering on circuit boards. Magnetic rings, made of the same material as ferrite beads, are used to clamp cables directly, making rectification verification convenient, typically for power or signal lines. Power filters are used when the product is near launch or when circuit boards cannot be easily rectified in later stages of development. A filter is added at the power input to effectively filter the signal, a simple and fast solution.

- Shielding: This includes overall shielding of the shell, local shielding, and cable shielding. Overall shielding involves enclosing the product in a metal case, which can effectively reduce radiated emissions but is less practical. Local shielding targets the source of excess emissions, applying shielding materials to reduce overall electromagnetic radiation. Cable shielding involves replacing signal cables with shielded cables or using cables with better shielding performance to effectively eliminate electromagnetic radiation from the cables.

- Grounding: This includes signal grounding, single-point grounding, and multi-point grounding. It is crucial to ensure that all necessary grounding points are properly grounded to avoid virtual connections. Grounding includes grounding the shell of clock signal components and the filter housing.

Six Steps of EMC Rectification

The six-step method for EMC rectification is suitable for common electronic devices. However, JJR Testing believes that while these methods can improve EMC radiation rectification efficiency, save time, and help pass EMC testing quickly, they do not fundamentally solve EMC issues. The ideal approach is to consider EMC at the design stage rather than relying on "firefighting" solutions post-design.

1. Locating and Confirming Radiation Sources: This includes exclusion methods (wiring method, partition exclusion method, low-voltage small current human touch method, etc.) and using a spectrum analyzer to search for frequency points and analyze the operating conditions of components with fixed frequencies (e.g., oscillators, DDR).

2. Filtering: Capacitor filtering, RC filtering, and LC filtering are used to suppress electromagnetic radiation.

3. Absorbing Electromagnetic Waves: This can be done by placing magnetic beads, wrapping magnetic rings, or using absorbing materials. Proper frequency matching of absorbing materials is critical, or absorption may fail.

4. Grounding: This includes single-point grounding and multi-point grounding methods to reduce radiation impact.

5. Shielding: Includes shielding enclosures and PCB routing shielding, blocking radiation propagation.

6. Energy Dispersion: Adjusting frequency bandwidth and hop frequency technology to disperse radiation energy, reducing the intensity of radiation at single frequencies and diminishing the effect of spike interference waveforms.

In general, these methods focus on analyzing, reducing, and suppressing electromagnetic radiation problems, suitable for EMC design and troubleshooting.

EMC Rectification Case Studies:

In addition to EMC testing, China JJR Laboratory also provides rectification solutions. We are committed to a "customer-first" approach and have successfully solved EMC issues for many clients.

For example, we helped a large electronics company address electromagnetic interference (EMI) issues in its products by providing source-level solutions. Through in-depth analysis of the interference sources, we successfully reduced product costs while ensuring product performance stability. Additionally, we offered a solution for a medical equipment manufacturer, implementing effective protection measures that reduced electromagnetic interference without affecting the device's performance, meeting high product quality standards.

EMC Rectification Projects:

- Conducted emission rectification

- Radiated emission rectification

- Electrostatic discharge rectification

- Surge rectification

- Fast transient burst rectification

- Harmonic current rectification

- Radiated immunity rectification

- Conducted immunity rectification

Medical Device EMC Rectification Methods:

1. Shielding: Use metal enclosures or add shielding to the main IC or SDRAM components on the PCB; spray conductive paint inside plastic enclosures or use electroplated shells.

2. Grounding: Widen the ground traces on the PCB; increase the grounding area between the PCB and the metal enclosure; ground large ICs using conductive foam or metal clips; reroute interference paths to reduce loop areas.

3. Filtering:

a. Add resistors (30-50Ω) to clock, data lines, I/O ports, and noisy circuits.

b. Add capacitors (10-100pF) to clock, power, data lines, I/O ports, and circuits to suppress noise.

c. Add inductors to power, keyboard, data lines, and clock.

d. Add beads to power, clock, data lines, and I/O ports.

e. Use filters or cores inside the machine and on external cables, including power lines.

f. Use common mode chokes on USB 2.0, DC power, and AC power.

g. Use LC or RC filters on clock, data lines, I/O ports, and power.

h. Use P-type filters at DC power input or IC power input ends.

i. Use T-type filters on noisy clock, data lines, I/O ports, DC power, and other circuits.

Completion Cycle:

- Regular product EMC rectification: 1-2 weeks

- Medical or complex EMC rectification: About 1 month

- emc certification reports for the EU, Australia, Canada, Japan, etc., from our laboratory: 1 week

Our Advantages:

- An experienced EMC rectification team to better serve enterprises.

- The lab's technical experts are professionally certified and offer customized testing plans and professional advice.

- Equipped with the latest testing devices and instruments to ensure the accuracy and reliability of test results.

Email:hello@jjrlab.com

Write your message here and send it to us

REACH und RoHS Konformität

REACH und RoHS Konformität

RoHS Konformität

RoHS Konformität

Richtlinie 2011/65/EU RoHS

Richtlinie 2011/65/EU RoHS

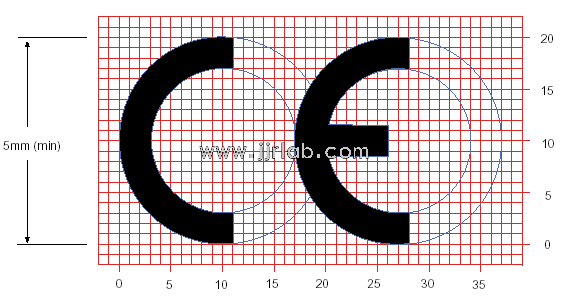

Wie bekomme ich die CE Kennzeichnung?

Wie bekomme ich die CE Kennzeichnung?

Was sagt die CE Kennzeichnung auf Medizinprodukten

Was sagt die CE Kennzeichnung auf Medizinprodukten

Was ist CE Kennzeichnung?

Was ist CE Kennzeichnung?

Was braucht die CE Kennzeichnung

Was braucht die CE Kennzeichnung

Was kostet CE-Kennzeichnung?

Was kostet CE-Kennzeichnung?

Leave us a message

24-hour online customer service at any time to respond, so that you worry!