Electric bicycle CE certification Testing Laboratory

CE certification requirements for light electric vehicles and electric bicycles

EN 17128:2020 Light motor vehicles for the transport of persons and goods and associated facilities, not type-approved for road use - Light electric vehicles (PLEV)

EN 15194 Bicycles Electric Assisted Bicycles - EPAC Bicycles

EN 50604-1 for Light Electric Vehicle Batteries

EN 62133-2 for portable or auxiliary system batteries

EN61558-1 EN61558-2-16 Adapter Charger

2014/30 / EU EMC Electromagnetic Compatibility

2011/65 / EU RoHS Toxic and Hazardous Prohibited Substances

2014/53 / EU RED Wireless Communications Directive

2006/42/EC MD Machinery Directive on Product Safety (en60204, ISO12100, ISO13849-1, EN61558-1/2-16, EN1020)

EN17128 Light Electric Vehicles

EN 17128:2020 "Light motor vehicles for the transport of persons and goods and associated facilities, not type-approved for road use - Light electric vehicles (PLEV)" was published on October 21, 2020. The standard was prepared by Technical Committee CEN/TC 354 and is held by the French Standards Association (AFNOR).

EN 17128:2020 applies to personal light electric vehicles with or without a self-balancing system, which are powered wholly or partly by a self-contained power supply with a battery voltage up to 100 VDC, with or without an integrated battery charger with an input of up to 240 VAC.

The standard specifies safety requirements, test methods, marking and information related to personal light electric vehicles to reduce the risk of injury to third parties and users during their intended use (i.e. when used as intended and under conditions of abuse that are reasonably foreseeable to the manufacturer).

EN 17128:2020 standard implementation time:

Key Dates for the New Standard

Effective Start Date (DAV): October 21, 2020

Publication Date (DOP): April 30, 2021

Mandatory Effective Date (DOW): April 30, 2021

EN 17128:2020 does not apply to:

1. Vehicles considered as toys;

2. Vehicles without automatic seat balancing system;

3. Vehicles used for competition;

4. Electrically assisted circulation (EPAC);

5. Vehicles and/or equipment intended for medical use;

6. Electric vehicles with a maximum design speed exceeding 25 Km/h;

7. Vehicles with a rated voltage exceeding 100 VDC or 240 VAC;

8. Vehicles without a driver on board.

Component testing requirements:

Component - Testing Standar

Battery - IEC/EN 62133-1 & IEC/EN 62133-2

Adapter/Charger - EN 60335-2-29 or EN 61558-1 & EN 61558-2-16

Headlight and Taillight - ISO 6742-1

Bell/Alarm Device - ISO 14878

Reflector - ISO 6742-2

Headlight and Taillight - ISO 6742-1

Bell/Alarm Device - ISO 14878

EN 17128:2020 test item outline:

4 Vehicle Types

5 General safety requirements and protective measures

6Electrical components

6.1 General mechanical strength

6.2 Power switch control

6.3 Cables and connections

6.4 Moisture resistance

6.5 Vibration resistance of electrical functions

7. Driver Power Management

7.1 Driver power activation

7.2 Control system power off

7.3 Unexpected or Unauthorized Use of Vehicle

8 Speed Limit

8.1 Pedestrian Mode

8.2 Maximum speed with power assistance

8.3 Reverse Mode

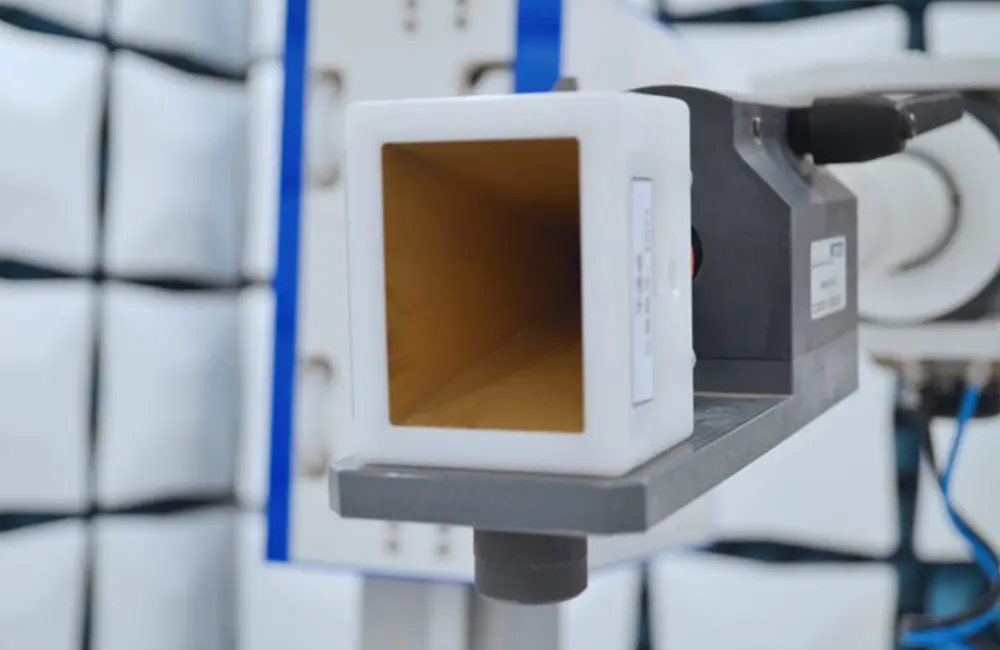

9 Electromagnetic compatibility

9.1 Emission

9.2 Immunity

9.3 Battery Charger

10. Battery Charging

10.3 Safeguards and Supplementary Protection Measures

11In -car energy storage

12 Structural Integrity

12.2 Static load test

12.3 Frontal impact resistance

12.4 Fatigue test (dynamic)

12.5 Procedure

13Edges and protrusions

13.2 Sharp Edges

13.3 Protruding parts

14 Moving Parts

14.1 Clearances between moving parts

14.2 Protection of moving parts

14.3 Folding mechanism

15 Adequate stability (see D.10)

15.1 Footboard/Deck

15.2 Handlebar Adjustment

15.3 Surface

15.4 Braking device

16 Existential Awareness

16.1 Lighting

16.2 Audible warning to alert personnel

17 System failure and fault alarm device

17.2 Sound/Vibration Signals

17.3 Loss of connection to the warning system

18 Hot Surface

19 Product information and marking

EN 15194 Bicycles - Electrically assisted bicycles - EPAC Bicycles

The standard is intended to cover all significant hazards, hazardous conditions and events common to power-assisted bicycles when used as intended and when misused by the manufacturer (see clause 4) except for EPAC bicycles used for rental at unattended stations.

The standard is intended to cover electric-assist bicycles with a maximum continuous power rating of 0.25 kW, whose output is gradually reduced and eventually cut off when the EPAC reaches a speed of 25 km/h, or earlier if the rider stops pedaling.

The standard specifies requirements and test methods for engine power management systems, circuits including charging systems used in the design and assembly of electric-assist bicycles, and system subassemblies rated up to 48 V DC or integrated battery chargers with a nominal 230 V AC input.

This standard specifies safety and safety-related performance requirements for the design, assembly, and testing of EPAC bicycles and components for use on public roads, and establishes guidelines for the use and maintenance instructions of such bicycles.

The standard applies to EPAC bicycles with a maximum seat height of 635 mm or more and used on public roads.

This standard does not apply to EPACs manufactured before the date of its publication as an EN.

EN15194 test project outline:

4 Safety requirements and/or protective measures

4.2 Electrical requirements

4.2.1 Circuit

4.2.2 Controls and symbols

4.2.3 Battery

4.2.4 Battery Charger

4.2.5 Cables and connections

4.2.6 Wiring

4.2.7 Power cables and conduits

4.2.8 External and internal electrical connections

4.2.9 Moisture resistance

4.2.10 Mechanical strength test

4.2.11 Maximum speed with motor assistance

4.2.12 Start auxiliary mode

4.2.13 Power Management

4.2.14 Maximum power measurement - measurement at the engine shaft

4.2.15 Electromagnetic compatibility

4.2.16 Failure Mode

4.2.17 Anti-tampering measures

4.3 Mechanical requirements

4.3.2 Sharp edges

4.3.3 Safety and strength of safety-related fasteners

4.3.4 Protruding parts

4.3.5 Braking

4.3.6 Steering

4.3.7 Framework

4.3.8 Front fork

4.3.9 Wheels and wheel/tire assemblies

4.3.10 Rims, tires and inner tubes

4.3.11 Front fender

4.3.12 Pedals and pedal/crank drive systems

4.3.13 Transmission chains and belts

4.3.14 Sprocket and belt drive protection devices

4.3.15 Seat and seat post

4.3.16 Spoke protection device

4.3.17 Luggage rack

4.3.18 Road testing of a fully assembled EPAC

4.3.19 Lighting systems and reflectors

4.3.20 Alarm device

4.3.21 Thermal hazards

4.3.22 Performance Level (PLrs) of EPAC Control System

4.4 Major Hazard List

5. Marking and labeling

5.2 Durability test

6 Instructions for use

Email:hello@jjrlab.com

Write your message here and send it to us

What is FCC Class A vs. Class B?

What is FCC Class A vs. Class B?

UL Standards for Electrical Equipment

UL Standards for Electrical Equipment

Is UL Certification Required in the USA?

Is UL Certification Required in the USA?

Wireless Microphone Export Certification

Wireless Microphone Export Certification

Audio-Visual Products SNI Certification in Indones

Audio-Visual Products SNI Certification in Indones

FCC-ID: Still Needed if Module is Certified?

FCC-ID: Still Needed if Module is Certified?

FCC Certification Fees for Handheld Fans

FCC Certification Fees for Handheld Fans

FCC Certification Testing for Smart Lighting Produ

FCC Certification Testing for Smart Lighting Produ

Leave us a message

24-hour online customer service at any time to respond, so that you worry!