Drill CE Certification EMC Testing

Drill EMC Testing Guide

As a common power tool, drills are widely used in home renovation, woodworking, and other fields. However, with the increasing prevalence of electronic devices and the complexity of electromagnetic environments, the electromagnetic compatibility (EMC) of drills has gained attention. EMC testing evaluates a drill's performance in electromagnetic environments, ensuring stable operation and compliance with relevant standards and regulations.

Drill EMC Testing Standards

The primary EMC testing standards for drills are based on the following European standards:

1. EN 55014-1: Electromagnetic compatibility testing (emissions) for household appliances and similar equipment.

2. EN 55014-2: Electromagnetic immunity testing for household appliances and similar equipment.

These standards cover emission and immunity requirements to ensure drills do not cause interference to their surroundings and can withstand external electromagnetic disturbances.

How to Perform EMC Testing for Drills

The EMC testing process for drills typically involves the following steps:

1. Testing Appointment: Contact a professional EMC testing agency to schedule a test and understand specific requirements and preparation details.

2. Sample Submission: Provide the drill sample to the testing agency along with technical documentation and related materials.

3. Preliminary Inspection: The agency performs initial checks, including visual inspections and functional testing, to confirm the sample meets basic testing conditions.

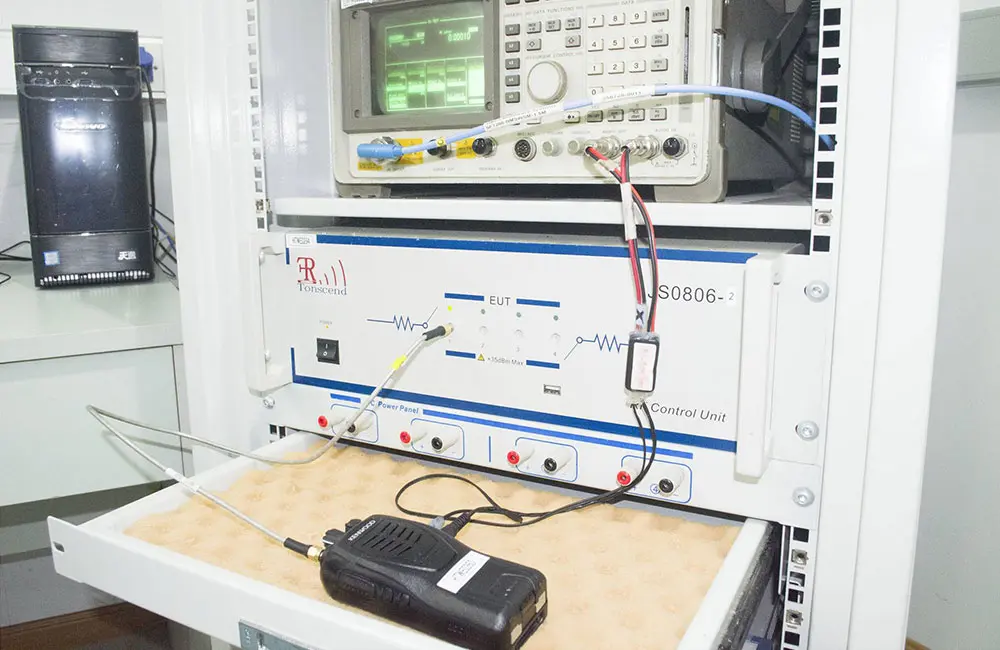

4. EMC Testing: The agency conducts EMC tests, including:

- Radiated Emission Test: Evaluates the drill's electromagnetic interference to the surrounding environment during operation.

- Conducted Emission Test: Assesses interference caused by the drill through power lines to the electrical grid.

- Radiated Immunity Test: Measures the drill's ability to resist external electromagnetic interference.

- Conducted Immunity Test: Evaluates resistance to interference conducted through power lines.

5. Analysis and Reporting: The agency analyzes test results and issues a detailed report specifying the drill's EMC performance and compliance with relevant standards.

6. Rectification and Retesting (if necessary): If the drill fails the initial EMC tests, the agency provides recommendations for rectification. The manufacturer can modify the product and resubmit it for testing.

7. Certificate Issuance: Upon passing the EMC tests, the agency provides a certificate or report to confirm the drill's compliance with EMC standards and regulations.

Importance of EMC Testing for Drills

EMC testing is vital for ensuring product quality and safety:

1. Improving Product Quality: Helps manufacturers identify and resolve EMC issues, enhancing reliability.

2. Ensuring Operational Safety: Verifies stable operation in complex electromagnetic environments, preventing interference-related failures or accidents.

3. Meeting Regulatory Requirements: Helps manufacturers comply with regulations and gain market access.

Choosing an EMC Testing Agency

Selecting a professional EMC testing agency ensures accurate and reliable results. Consider these factors:

1. Accreditation: Choose an agency with proper certifications.

2. Technical Expertise: Opt for agencies with experience and specialized skills offering comprehensive EMC testing.

3. Service Quality: Select agencies known for efficient and high-quality services.

JJR Laboratory in China can provide comprehensive EMC testing services. Contact us for more information!

Email:hello@jjrlab.com

Write your message here and send it to us

Temu Requires UN 38.3 Certification

Temu Requires UN 38.3 Certification

What is the Amazon ASTM F2057 Test Report?

What is the Amazon ASTM F2057 Test Report?

How to get the Amazon SOR/2016-175 Test Report?

How to get the Amazon SOR/2016-175 Test Report?

Amazon Electronic Product UL Test Report

Amazon Electronic Product UL Test Report

What is the 4.3 Toxicology Test in ASTM F963?

What is the 4.3 Toxicology Test in ASTM F963?

What is the Canada Tent SOR/2024-217 Test Report?

What is the Canada Tent SOR/2024-217 Test Report?

How to get the Amazon AS/NZS 1900 Test Report?

How to get the Amazon AS/NZS 1900 Test Report?

Children's Jewelry CPC Certification and ASTM F292

Children's Jewelry CPC Certification and ASTM F292

Leave us a message

24-hour online customer service at any time to respond, so that you worry!