China GB Testing for Power Tools

Nowadays, power tools are increasingly used in daily life and production. Safety testing can prevent accidents and injuries caused by the use of power tools. The JJR Laboratory in China provides safety, performance, and electromagnetic compatibility (EMC) testing services for various types of power tools.

Our power tool testing services include:

- Safety of Hand-Held Motor-Operated Electric Tools Part 1: General Requirements (GB 3883.1—2005)

- Safety of Hand-Held Motor-Operated Electric Tools Part 2: Particular Requirements for Grinders, Polishers, and Disc-Type Sanders (GB 3883.3—2007)

- Angle Grinders (GB/T 7442-2007)

- Safety of Hand-Held Motor-Operated Electric Tools Part 2: Particular Requirements for Drills and Impact Drills (GB 3883.6—2012)

- Electric Drills (GB/T 5580-2007)

- Safety of Hand-Held Motor-Operated Electric Tools Part 2: Particular Requirements for Hammers (GB 3883.7-2012)

- Electric Hammers (GB/T 7443-2007)

Power Tool Safety Testing

- Markings and instructions

- Starting

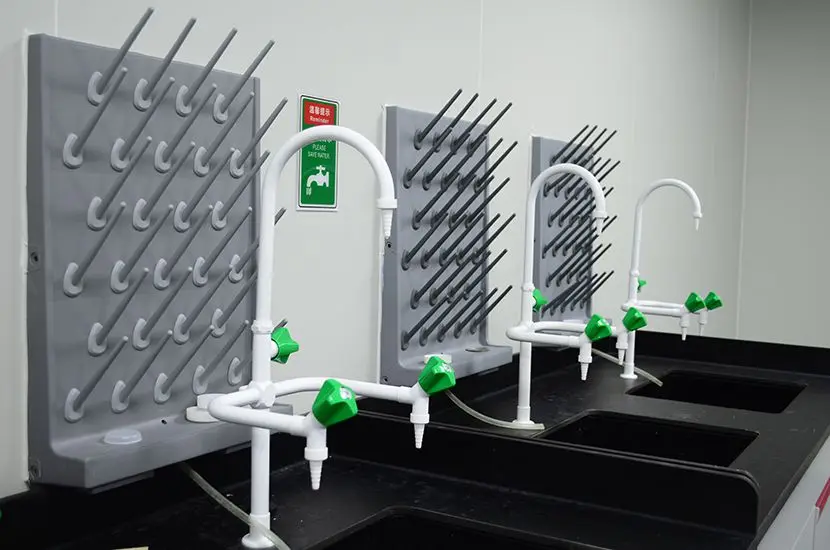

- Moisture resistance

- Overload protection for transformers and related circuits

- Structure

- Power connection and external flexible cords

- Grounding devices

- Creepage distance

- Resistance to heat

- Protection against access to live parts

- Leakage current

- Electrical strength

- Mechanical hazards

- Internal wiring

- Terminals for external conductors

- Screws and connections

- Clearance and insulation distances

- Flame retardancy and resistance to tracking

- Rust prevention

Performance Testing

- Dynamometer testing for speed

- Power

- Temperature rise

- Surface treatment of screws

- Over-torque

- Torque

- Noise

- Power cord length

- Stall testing

- Dimensions (flanges, drill sizes)

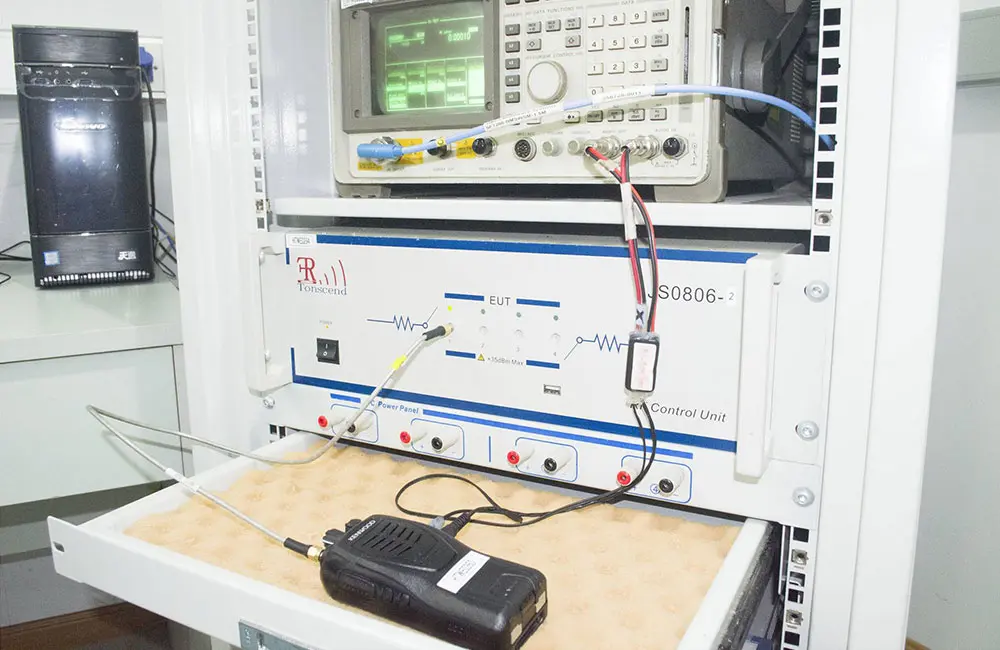

Electromagnetic Compatibility Testing (according to GB 4343-2009)

- Conducted emissions

- Harmonic current

- Electrostatic discharge (ESD)

- Surge

- Voltage dips

- Radiated emissions

- Voltage fluctuations

- Electrical fast transients (EFT)

- Power frequency magnetic field

Email:hello@jjrlab.com

Write your message here and send it to us

Australia RCM LOGO Certification

Australia RCM LOGO Certification

ANATEL Certification Process in Brazil

ANATEL Certification Process in Brazil

Faucet European Standard EN 817 Testing

Faucet European Standard EN 817 Testing

ISO 17025 Laboratory Test Report

ISO 17025 Laboratory Test Report

Temu Requires UN 38.3 Certification

Temu Requires UN 38.3 Certification

What is the Amazon ASTM F2057 Test Report?

What is the Amazon ASTM F2057 Test Report?

How to get the Amazon SOR/2016-175 Test Report?

How to get the Amazon SOR/2016-175 Test Report?

Amazon Electronic Product UL Test Report

Amazon Electronic Product UL Test Report

Leave us a message

24-hour online customer service at any time to respond, so that you worry!