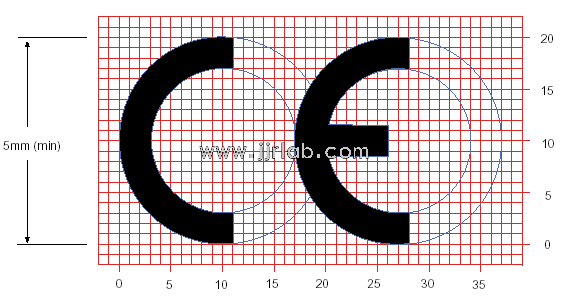

CE Marking for Electrical Equipment

The CE marking for electrical equipment under the low voltage directive covers all electrical products with nominal AC voltages between 50 and 1000V and nominal DC voltages between 75 and 1500V. These products must meet specific electrical safety requirements, such as insULation distance, high-voltage endurance, fire resistance, temperature rise limitations, lifespan of critical components, and testing for abnormal conditions.

CE certification refers to a mandatory certification system for products that comply with European Union regulations. For CE certification, the en60950 safety standard plays a crucial role, and its testing requirements are particularly challenging. EN60950, issued by the European Commission, is a safety standard for information technology equipment. It sets out the safety requirements and testing methods for electrical equipment, making it an essential certification for electronic device manufacturers.

The EN60950 standard includes the following key areas:

1. Electrical Safety Requirements: EN60950 mandates that electrical equipment ensures user safety, including requirements for grounding, insulation, and voltage endurance.

2. Fire Risk Requirements: Since electronic devices may generate high temperatures during operation, EN60950 specifies requirements for heat dissipation design, internal structure, and the use of electrical components.

3. Mechanical Requirements: Materials and designs of the equipment's casing, wires, and connectors must comply with EN60950 to ensure users are protected from mechanical hazards.

4. Radiation Requirements: Especially for power sources and optical equipment, EN60950 limits device emissions to ensure no negative impact on human health.

The EN60950 testing requirements are equally stringent, covering but not limited to:

1. Electrical Safety Testing: This includes testing the grounding resistance, insulation resistance, and voltage endurance of the equipment to prevent electric shock hazards during use.

2. Fire Risk Testing: Evaluates the high-temperature durability of internal components, flammability, and the release of harmful substances to minimize fire risks.

3. Mechanical Testing: Includes impact tests on the casing and twist tests for wires to verify mechanical strength under normal and accidental conditions.

4. Radiation Testing: Ensures that emissions are within safe limits to protect user health.

The rigorous requirements and extensive testing involved in the EN60950 standard mean that passing CE certification demands high standards in both product design and manufacturing. Manufacturers must consider EN60950 requirements from the design stage onward, addressing electrical, structural, and radiation characteristics to ensure that the product meets these testing criteria by the production phase.

For manufacturers, products passing the EN60950 tests not only qualify for ce marking but also demonstrate enhanced product safety and quality, boosting competitiveness and market acceptance. Thus, manufacturers should thoroughly understand and adhere to EN60950 requirements throughout design, production, and testing to ensure compliance and quality, facilitating market entry and sales.

In summary, EN60950 is a key safety standard issued by the European Commission for electrical equipment. For CE certification, manufacturers must fully understand and comply with EN60950 requirements, ensuring product safety and quality from design to testing, thereby providing robust assurance for market access and product sales.

Email:hello@jjrlab.com

Write your message here and send it to us

How Do You Get a CE Mark

How Do You Get a CE Mark

IEC 60529 IP Rating Ingress Protection Standard

IEC 60529 IP Rating Ingress Protection Standard

IEC 60601-1 Medical Electrical Equipment Basic Saf

IEC 60601-1 Medical Electrical Equipment Basic Saf

European Authorized Representative Medical Devices

European Authorized Representative Medical Devices

EU Waste Electrical and Electronic Equipment Direc

EU Waste Electrical and Electronic Equipment Direc

How to Get CE Approval

How to Get CE Approval

Accelerated Ageing Test

Accelerated Ageing Test

IP Ingress Protection Testing

IP Ingress Protection Testing

Leave us a message

24-hour online customer service at any time to respond, so that you worry!