CE Certification for Mechanical Equipment

Machinery MD Directive

CE certification is a mandatory conformity assessment required by EU law, aimed at ensuring the safety, health, and environmental protection of products in the European market. Within this framework, the Machinery Directive CE-MD is a crucial directive for machinery and equipment. It mandates that all machinery products sold in the European market comply with a series of rigorous safety standards and technical specifications. The latest Machinery Directive, effective from December 21, 2009, is 2006/42/EC Machinery Directive, commonly abbreviated as MD.

Scope of the Machinery Directive

Machinery and Machines: e.g., production lines, industrial robots, construction and mining equipment, machine tools, elevators, cranes, industrial vehicles, etc.

Transport Equipment: e.g., cars, motorcycles, bicycles, scooters, roller skates, skateboards, etc.

Household Appliances and Home Equipment: e.g., household and similar mechanical devices.

Sports and Entertainment Equipment: e.g., fitness equipment, amusement rides, swimming pools, yachts, etc.

Other Machinery or Equipment: e.g., explosion-proof equipment, safety doors, firefighting equipment, elevators, stage lighting equipment, hazardous material storage equipment, garden machinery, etc.

Certification Models for Machinery CE Certification

Regular Machinery

- A Module (Internal production control, EC declaration of conformity, Annex VIII)

Hazardous Machinery (Manufactured according to harmonized standards)

- A Module (Internal production control, Annex VIII)

- B Module (EC type-examination + internal production control assessment, Annex IX + Annex VIII, point 3)

- H Module (Comprehensive quality assurance system, Annex X)

Hazardous Machinery (Manufactured partially or not according to harmonized standards, or without harmonized standards)

- B Module (EC type-examination + internal production control assessment, Annex IX + Annex VIII, point 3)

- H Module (Comprehensive quality assurance system, Annex X)

Definition of Hazardous Machinery

Annex IV of the Machinery Directive details machinery and safety components considered high-risk by the EU. These machines or components are termed hazardous machinery. The distinction between hazardous and non-hazardous machinery lies in the requirement for on-site assessment by an EU notified body and the issuance of a certificate, which is not accepted based solely on self-declaration by buyers and regulatory authorities.

The following are hazardous machinery specified in Annex IV of the Machinery Directive:

(1) Circular saws (single or multiple blade) for processing wood or similar materials, or meat or similar materials, including:

— Circular saws with fixed bed or support, manually fed or fitted with removable power feed, with fixed saw blade during cutting;

— Reciprocating saws or sliding tables operated manually with fixed saw blade during cutting;

— Circular saws with integrated mechanical feed unit, manual loading and unloading, with fixed saw blade during cutting;

— Circular saws with mechanically movable saw blades, manual loading and unloading, with moving saw blades during cutting;

(2) Hand-fed woodworking planing machines;

(3) Single-sided planing machines for woodworking with integrated mechanical feed unit, manual loading and unloading;

(4) Band saws for processing wood or similar materials, or meat or similar materials, including:

— Band saws with fixed or reciprocating bed or support, with fixed saw blade during cutting;

— Band saws with saw blade mounted on reciprocating frame;

(5) Combination machines of the types listed under points 1 to 4 and point 7 for woodworking or similar materials;

(6) Hand-fed tenoning machines with multiple spindles for woodworking;

(7) Vertical woodworking machines for woodworking or similar materials operated manually;

(8) Hand-held woodworking chain saws;

(9) Hand-operated presses for cold working of metal with manual loading and unloading, with a working stroke exceeding 6 mm, and a speed exceeding 30 mm/s, including bending machines;

(10) Hand-operated injection or extrusion molding machines for plastics with manual loading and unloading;

(11) Hand-operated injection or extrusion molding machines for rubber with manual loading and unloading;

(12) Underground mining machinery, including:

— Locomotives and wagons;

— Hydraulic support equipment;

(13) Human-powered loading vehicles with compressing devices for collecting household waste;

(14) Removable mechanical transmission devices and their protective covers;

(15) Protective covers for removable mechanical transmission devices;

(16) Automotive lifting equipment;

(17) Lifting equipment for raising people or goods to a vertical height exceeding 3 meters with a risk of falling objects;

(18) Hand-held powder-actuated fastening tools and other impact tools;

(19) Protective devices for detecting human exposure to hazardous areas;

(20) Power-driven interlocking guards on equipment listed in items 9, 10, and 11;

(21) Logic units ensuring safety functions;

(22) Roll-over protective structures (ROPS);

(23) Falling object protective structures (FOPS).

Core Requirements of the Machinery Directive

Machinery design and manufacture must comply with relevant standards of the European Union.

Machinery must be equipped with necessary safety devices such as emergency stop devices, protective devices, etc.

Machinery must be capable of automatically stopping or returning to a safe position under abnormal operating conditions.

Operators must take appropriate safety measures when operating machinery.

Manufacturers of machinery must provide necessary safety instructions and technical documentation.

Common Test Items under the Machinery Directive

1. Structural safety testing of machinery: Ensuring the structural integrity of machinery products to withstand loads and pressures under intended use.

2. Electrical safety testing: Testing of electrical components in machinery products to ensure compliance with electrical safety requirements, such as insulation performance, electromagnetic compatibility, etc.

3. Operational stability testing: Testing the operational stability and reliability of machinery products under normal operating conditions, including performance during operation, stoppage, emergency stops, etc.

4. Safety testing of mechanical moving parts: Testing of moving parts (e.g., rotating shafts, transmission belts) in machinery products to ensure they do not pose hazards to personnel during operation.

5. Noise and vibration testing: Testing the levels of noise and vibration generated by machinery products during operation to ensure they are within safe limits.

6. Evaluation of user manuals: Assessment of the clarity and completeness of product manuals, including necessary safety warnings and operating instructions, to ensure correct usage by users.

7. Emergency stop performance testing: Testing the emergency stop performance of machinery products to ensure they can quickly halt operation in dangerous situations, protecting user safety.

8. Chemical substance safety testing: Testing for potentially harmful chemical substances in machinery products to ensure they do not contain substances harmful to human health.

The above testing items are just part of CE-MD certification, and specific testing items may vary depending on the type and intended use of the machinery product. Once all testing items are completed and assessed, the product can obtain CE-MD certification.

China JJR Laboratory is an ISO 17025 accredited laboratory, providing CE certification testing services for mechanical equipment. We can help you save 30% on certification fees. Feel free to contact us for consultation.

Email:hello@jjrlab.com

Write your message here and send it to us

What is the 4.3 Toxicology Test in ASTM F963?

What is the 4.3 Toxicology Test in ASTM F963?

What is the Canada Tent SOR/2024-217 Test Report?

What is the Canada Tent SOR/2024-217 Test Report?

How to get the Amazon AS/NZS 1900 Test Report?

How to get the Amazon AS/NZS 1900 Test Report?

Children's Jewelry CPC Certification and ASTM F292

Children's Jewelry CPC Certification and ASTM F292

Amazon Ladder Compliance Certification Guide

Amazon Ladder Compliance Certification Guide

Amazon and Temu Require FCM Test Reports

Amazon and Temu Require FCM Test Reports

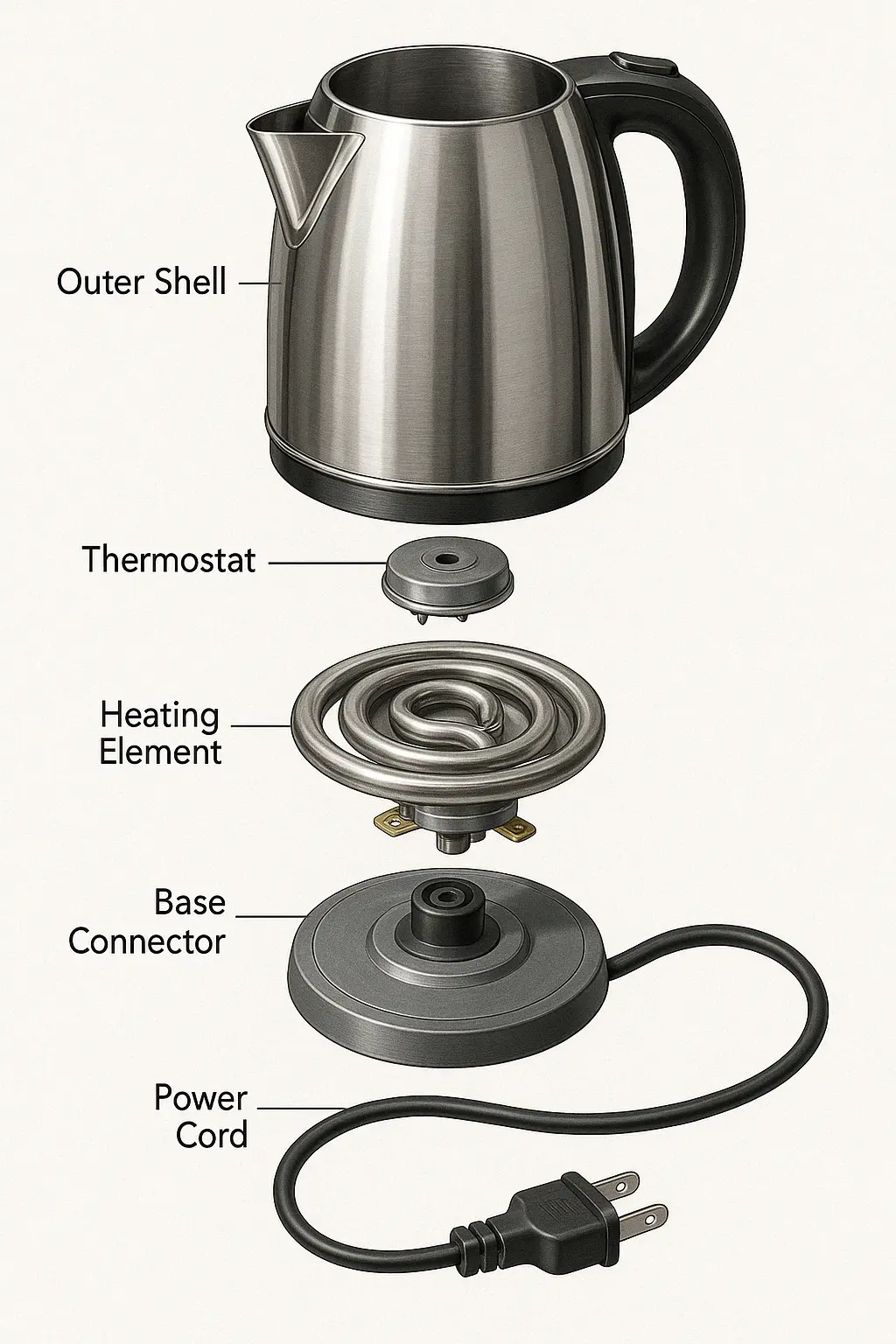

Electric Kettle Amazon Canada Compliance Certifica

Electric Kettle Amazon Canada Compliance Certifica

Do You Understand Amazon Compliance Certification?

Do You Understand Amazon Compliance Certification?

Leave us a message

24-hour online customer service at any time to respond, so that you worry!