CE Certification for Electronic and Electrical Products

The CE certification standards and process for electronic and electrical products can be divided into the following key steps. CE certification ensures products comply with the EU's safety, health, and environmental protection requirements.

Determine Applicable Directives and Standards

Electronic and electrical products typically need to comply with the following major directives and standards:

1.1 low voltage directive (LVD, 2014/35/EU):

Applicable to electrical equipment with a rated voltage between 50V to 1000V AC and 75V to 1500V DC.

1.2 Electromagnetic Compatibility Directive (EMC, 2014/30/EU):

Ensures that devices do not produce excessive electromagnetic interference and are resistant to electromagnetic disturbances.

1.3 RoHS Directive (2011/65/EU):

Restricts the use of certain hazardous substances.

1.4 Other Relevant Directives:

For example, the Radio Equipment Directive (RED, 2014/53/EU), among others.

Product Testing and Evaluation

Conduct product testing and evaluation based on applicable directives:

2.1 Internal Testing:

Manufacturers can conduct preliminary evaluations internally.

2.2 External Testing:

Use third-party laboratories for formal testing, especially for specialized equipment and expertise requirements.

Technical Documentation

Prepare and organize technical documentation, typically including:

- 3.1 Product Description

- 3.2 Design and Manufacturing Drawings

- 3.3 Electrical Schematics

- 3.4 Risk Assessment Analysis

- 3.5 Applicable EU Standards

- 3.6 Test Reports

- 3.7 User Manuals and Safety Information

Determine Conformity Assessment Routes

Select the appropriate conformity assessment route based on product complexity and risk level:

4.1 Self-Declaration:

For low-risk products, manufacturers can perform their own conformity assessments.

4.2 Involvement of a Notified Body:

High-risk products usually require assessment and certification by an EU Notified Body.

Conformity Assessment and Testing

- 5.1 Self-Assessment:

If applicable, manufacturers evaluate product conformity based on technical documentation and test resULts.

- 5.2 Notified Body Assessment:

If required, involve a Notified Body for evaluation and testing to obtain relevant certificates and reports.

Sign the Declaration of Conformity (DoC)

The manufacturer signs the EU Declaration of Conformity, confirming that the product complies with all applicable directives and standards.

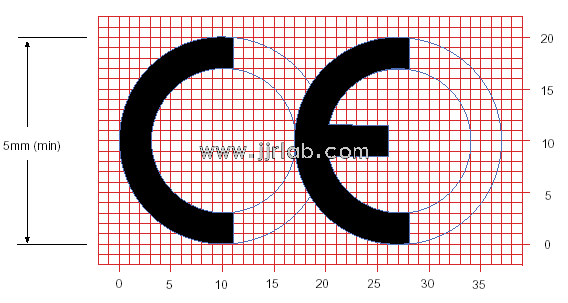

Affix the ce marking

Affix the ce marking to the product, ensuring it meets the prescribed dimensions and format.

Maintain Technical Documentation

Manufacturers must retain the technical documentation for at least 10 years, for inspection by EU market surveillance authorities.

Ensure Continuous Compliance

Ensure the product maintains compliance with CE certification requirements throughout its lifecycle, including periodic updates to technical documentation and quality control.

Example Process Flow

1. Determine Directives and Standards

2. Product Testing and Evaluation

3. Prepare Technical Documentation

4. Choose Assessment Route

5. Conduct Conformity Assessment and Testing

6. Sign the Declaration of Conformity

7. Affix the CE Marking

8. Maintain Technical Documentation

9. Ensure Continuous Compliance

Obtaining CE certification for electronic and electrical products is a systematic process. Manufacturers must thoroughly understand the applicable directives and standards, conduct rigorous testing and evaluations, prepare comprehensive technical documentation, and maintain long-term compliance. Following the above steps ensures the product successfully enters the EU market while meeting safety, health, and environmental protection requirements.

Email:hello@jjrlab.com

Write your message here and send it to us

How Do You Get a CE Mark

How Do You Get a CE Mark

IEC 60529 IP Rating Ingress Protection Standard

IEC 60529 IP Rating Ingress Protection Standard

IEC 60601-1 Medical Electrical Equipment Basic Saf

IEC 60601-1 Medical Electrical Equipment Basic Saf

European Authorized Representative Medical Devices

European Authorized Representative Medical Devices

EU Waste Electrical and Electronic Equipment Direc

EU Waste Electrical and Electronic Equipment Direc

How to Get CE Approval

How to Get CE Approval

Accelerated Ageing Test

Accelerated Ageing Test

IP Ingress Protection Testing

IP Ingress Protection Testing

Leave us a message

24-hour online customer service at any time to respond, so that you worry!