Button Battery UL4200A Compliance Certificate

Who can handle the UL4200A report for button battery products? The regulatory requirements for button batteries stem from a serious safety incident in the U.S. market. In 2020, a girl named Reese Hamsmith tragically died in Texas after swallowing a button battery from a TV remote control.

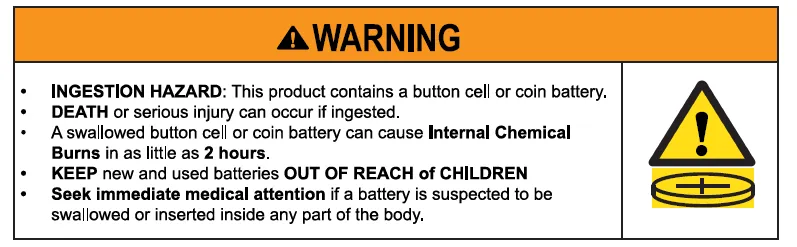

Since then, U.S. regulatory agencies have voted to establish new safety standards for button batteries to eliminate or significantly reduce the risk of injuries to children aged 6 and under from ingesting button or coin batteries. This led to the introduction of new regulations, UL4200A-2023, which require consumer products and household items containing button batteries to undergo testing and obtain GCC certification before they can be sold.

Button Battery Styles and Applications

Button batteries are widely used in various small electronic products to provide stable power support. Due to their larger diameter and thinner thickness, button batteries play an important role in the following areas:

- Portable devices: such as mobile phones, tablets, and Bluetooth speakers, which typically contain button batteries to ensure proper functioning and continuous power supply.

- Home appliances: including smart home controllers and smart locks, which also use button batteries as a power source, offering users a convenient and smart lifestyle experience.

As technology continues to develop, the scope of button battery applications will become even broader, making their safety an important concern.

Amazon Policy for Consumer Products Containing Button or Coin Batteries

Consumer products containing button or coin batteries must pass UL4200A standard testing and have the corresponding GCC compliance certificate before they can be listed and sold.

ANSI/UL 4200a Standard

This standard primarily aims to prevent the risk of injury from swallowing button or coin batteries and includes the following requirements:

1. Structural Inspection

For removable/replaceable batteries:

1) Remove removable components (which can be independently moved using two actions without tools or minimal effort by hand) and use test probes to ensure they do not touch the button/coin battery.

2) Products with removable or replaceable button/coin batteries should be designed to prevent children from removing the battery by one of the following methods:

a) The battery compartment must require tools, such as a screwdriver or coin, to open. For battery compartments fixed with screws or twist-off covers, opening the compartment requires at least 0.5 Nm of torque and a rotation angle of at least 90 degrees, or fasteners should engage at least two full threads. Note that if screws or similar fasteners are used to secure the door or cover to the battery compartment, the fasteners should secure the door, cover, or device.

b) The battery compartment door or cover should require at least two independent actions to open by hand. The actions cannot be combined with a single finger or single hand action.

For non-removable/replacable batteries:

a) The outer casing or similar devices must prevent access using tests as per sections 6.2 and 6.3.

b) The battery must be securely fixed using welding, fasteners (e.g., rivets), or equivalent methods, which should pass the safety test in section 6.4.

The installation integrity of non-removable batteries should be tested using a 20±2 N outward force for 10 seconds, and the battery must not be detached.

2. Performance Testing

1) Pre-treatment Tests:

Stress relief test: 70°C or higher (actual temperature rise test), 7 hours

Battery replacement test: Opening/closing the battery compartment and replacing the battery 10 times.

2) Abuse Tests:

Drop test: Portable products: 1 meter, 3 times; handheld products: 1 meter, 10 times

Impact test: 2 joules, 3 times, with a 50.8mm diameter, 500g steel ball

Compression test: 330 ±5 N (74.2 ±1.1 lbf), 10 seconds

Torque test: 0.50 Nm (4.4 in-lbf), 10 seconds

Tension test: 72.0 N (16.2 lbf), 10 seconds

Compression test: 136 N (30.6 lbf), 10 seconds

3) Battery Compartment Safety Test:

Using a test hook, apply a 20±2 N outward force for 10 seconds, and the battery must not be detached.

GCC Certification Required Documents or Information:

1. Application form: Applicant/manufacturer/production factory/company name (in English), address, contact person, phone number, fax number, email, etc.

2. Basic report and certificate details, including product name, model, ASIN number, trademark (if any), production date, batch number, U.S. representative (depending on need, which we may provide).

3. Product manual (battery parameters, product labels, declarations, etc.)

Email:hello@jjrlab.com

Write your message here and send it to us

Eyewear Product Certification Testing Laboratory

Eyewear Product Certification Testing Laboratory

Reading Glasses EN 14139 Testing

Reading Glasses EN 14139 Testing

UL 217 Smoke Detectors Test

UL 217 Smoke Detectors Test

Dioctyl Phthalate Test Laboratory

Dioctyl Phthalate Test Laboratory

What is Dioctyl Phthalate Test?

What is Dioctyl Phthalate Test?

What is EN 55024 Testing?

What is EN 55024 Testing?

GPSR Labeling Requirements

GPSR Labeling Requirements

ISTA 3A Testing Services

ISTA 3A Testing Services

Leave us a message

24-hour online customer service at any time to respond, so that you worry!