Biological Evaluation of Respiratory Airway Products

Recent Recalls of Respiratory Airway Products

Recently, Sentec and Percussionaire announced a recall of the VDR-4 Phasitron respiratory circuit kit due to potential failures in the Venturi component, leading to malfunction. This is not the first recall of respiratory airway products; in recent years, frequent recalls have occurred within the medical device industry. One of the most severe cases involved the recall of CPAP ventilators due to the degradation of polyester-based polyurethane (PE-PUR) sound abatement foam, which posed significant health risks. These issues have drawn heightened attention from the FDA, particularly concerning the potential release of leachables, volatile organic compounds (VOCs), and particulate matter from airway device materials.

Interpretation of the ISO 18562 Series Standards

The ISO 10993 series provides a comprehensive framework for the biological evaluation of medical devices in direct contact with the human body. However, it does not adequately address the biocompatibility assessment of airway materials and components that have "indirect contact" with patients. The ISO 18562 series was developed to bridge this gap, outlining specific requirements for airway assessments. It prioritizes chemical composition testing and in vitro models to minimize the use of test animals. Additionally, it provides regulatory authorities with targeted review standards and guidelines.

The ISO 18562 series was first published in 2017, with a revised version released in March 2024. However, it is important to note that ISO 18562 does not cover all biological risks associated with respiratory airway products. Additional evaluations may be necessary to establish a comprehensive biological assessment. For instance, while ISO 18562-4 addresses leachables in condensate, if the respiratory airway device is exposed to humidified drugs or liquids, it may require further testing per ISO 10993-18:2020, using solvents of different polarities for extractable studies.

Overview of ISO 18562 Standards

ISO 18562-1: Evaluation and Testing within a Risk Management Process

This foundational document defines the scope, terminology, risk analysis, test parameters, and permissible exposure levels for unknown impurities, providing general principles for biological evaluation.

ISO 18562-2: Tests for Emissions of Particulate Matter

- Specifies the required particle size ranges and limits:

- Particles ≤2.5 μm must not exceed 12 μg/m³

- Particles ≤10 μm must not exceed 150 μg/m³

- Provides three test methods for measuring the number and size of particulates in medical device gas pathways: membrane filtration, chronic particle separator, and particle counting.

ISO 18562-3: Tests for Emissions of Volatile Organic Substances

- Focuses on the release of volatile organic compounds (VOCs)

- Defines requirements for materials, testing methods, environmental conditions, repeatability, and emission limits

- Involves collecting and analyzing respiratory gas samples to determine VOC content and assess compliance with exposure limits to ensure patient safety.

ISO 18562-4: Tests for Leachables in Condensate

- Specifies testing requirements for harmful chemicals that may be released from airway equipment due to condensation (e.g., organic impurities, metal elements).

- Utilizes advanced analytical techniques such as gas chromatography-mass spectrometry (GC-MS) and liquid chromatography-mass spectrometry (LC-MS) for quantitative analysis to identify potential health risks.

Biocompatibility Assessment of Respiratory Tubing

Respiratory tubing, commonly structured in an "H" or straight corrugated design, may be axially extendable. "H"-shaped tubes consist of inspiratory and expiratory branches and are typically made from plastic or silicone rubber. They are widely used in ventilators, anesthesia machines, masks, or tracheal intubation devices and can be either disposable or reusable. Under extreme conditions, cumulative contact duration may exceed 30 days, classifying them as long-term contact devices.

Recommended Biological Testing Plan

Based on contact type and duration, the following biological evaluation endpoints and test standards are recommended for long-term contact (≥30 days) with humidified gas or liquid (drug solution/water):

1. Particulate Matter Emission Assessment

- Test Standard: ISO 18562-2:2024

- Required for Long-term Contact: Yes

2. Volatile Gas Emission & Toxicological Risk Assessment

- Test Standard: ISO 18562-3:2024, ISO 10993-17:2023

- Required for Long-term Contact: Yes

3. Extractables/Leachables & Toxicological Risk Assessment in Condensate

- Test Standard: ISO 10993-18:2020, ISO 18562-4:2024, ISO 10993-17:2023

- Required for Long-term Contact: Yes

4. Cytotoxicity

- Test Standard: iso 10993-5:2009

- Required for Long-term Contact: Yes

5. Sensitization

- Test Standard: iso 10993-10:2021

- Required for Long-term Contact: Yes

6. Irritation

- Test Standard: iso 10993-23:2021

- Required for Long-term Contact: Yes

7. Pyrogenicity (FDA Recommendation)

- Test Standard: ISO 10993-11:2017

- Required for Long-term Contact: Yes

Challenges in Extractables and Leachables (E&L) Analysis

Respiratory airway devices have large surface areas, making their analytical assessment thresholds (AET) very low. These devices are typically made of plastic or silicone rubber, requiring high extraction efficiency and presenting analytical challenges. Extractables/leachables studies and toxicological risk assessments face significant difficulties due to:

- Insufficient analytical sensitivity, which may result in underestimating or missing low-concentration extractables/leachables.

- Potential health risks from unassessed toxic substances, which could lead to organ failure, genetic damage, or increased cancer risk.

Comprehensive Biological Evaluation Services from JJR Lab

With over a decade of global regulatory submission experience, JJR Lab provides integrated biological evaluations for respiratory airway products. Our professional team, comprehensive testing capabilities, and regulatory accreditations enable us to support the global registration of:

- Anesthesia machines

- Respiratory masks

- Humidifiers

- Respiratory tubing and circuits

- CPAP machines

- Airway drug delivery devices, and more.

We deliver scientifically robust biological risk assessments, minimizing regulatory deficiencies and ensuring successful market approvals for our clients' products.

Email:hello@jjrlab.com

Write your message here and send it to us

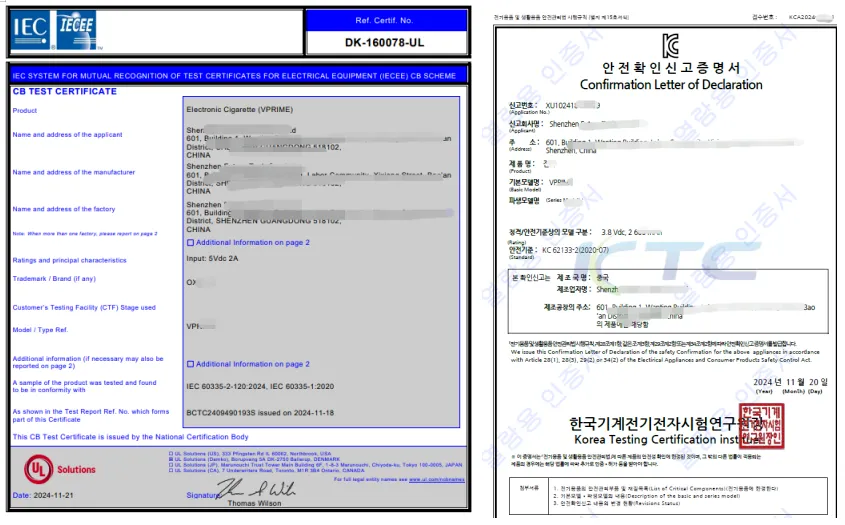

How to get the CB+KC Certification for E-Cigarette

How to get the CB+KC Certification for E-Cigarette

How to get UAE ECAS Certification?

How to get UAE ECAS Certification?

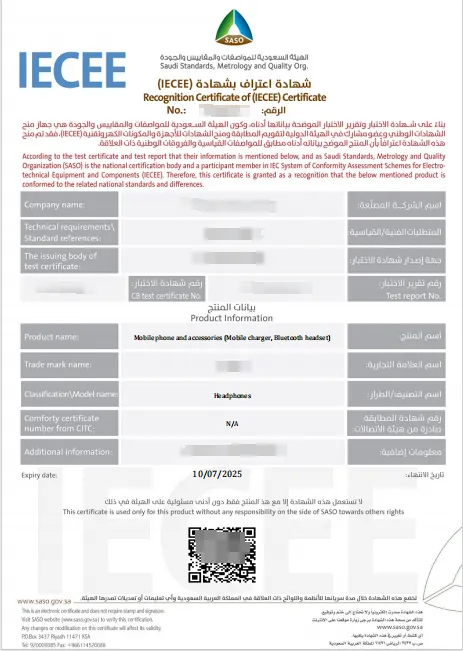

How to get Saudi IECEE Certification?

How to get Saudi IECEE Certification?

How to get the Singapore PSB Certificate?

How to get the Singapore PSB Certificate?

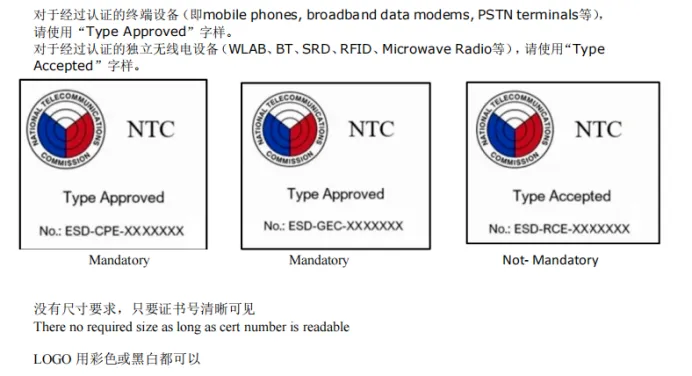

How to get the Philippines NTC Certificate?

How to get the Philippines NTC Certificate?

Understanding US CPSIA Product Certification

Understanding US CPSIA Product Certification

How Much Does CPSIA Certification Cost?

How Much Does CPSIA Certification Cost?

CPSIA Certification Requirements

CPSIA Certification Requirements

Leave us a message

24-hour online customer service at any time to respond, so that you worry!