Amazon US Site Requires UL 4200A 2023 Test Report

Button batteries are used in many consumer products, most commonly in remote controls. According to relevant data, every 75 minutes, a child is treated in the emergency room for battery-related injuries, with ingestion being the main cause of these visits, and 85% of the cases involve button batteries. If a child accidentally swallows a button battery, it can get stuck in the throat, triggering an electrical current upon contact with saliva, causing a chemical reaction that can burn through the esophagus, trachea, and aorta in severe cases. These dangers can occur within two hours, and even after the battery is removed, the severity of the burns can continue to worsen. Additionally, depleted batteries can still carry enough charge to cause serious injury and death.

In September 2023, the U.S. Consumer Product Safety Commission (CPSC) voted to approve UL 4200a-2023 as a mandatory consumer product safety rule for products containing button batteries, aiming to reduce ingestion hazards for children 6 years old and younger.

Note: Products containing button batteries must comply with UL 4200A requirements for export to the United States, regardless of whether the button batteries are replaceable or rechargeable.

Amazon Policy for Consumer Products Containing Button or Coin Batteries

Amazon requires all consumer products containing button or coin batteries and falling under the scope of 16CFR Part 1263 to be tested and comply with the following regulations, standards, and requirements. Therefore, sellers must pay extra attention to product safety, as non-compliant products will be removed by Amazon.

Products and Requirements

Consumer products containing button or coin batteries:

- Compliance with all the following:

- 16CFR Part 1263 - Safety standards for button or coin batteries and consumer products containing such batteries

- ANSI/UL 4200 - Safety standards for products containing button or coin batteries

UL 4200A Requirements

UL 4200A includes comprehensive requirements for products containing button batteries in terms of structure, testing, warning labels (on the product and packaging), and manuals.

Structure

1. For products with "user-replaceable or movable batteries," the structure must meet the following requirements:

- The IEC61032 test probe No. 11 must not contact the battery. Enclosures that can be opened without tools or with fewer than two independent and consecutive actions must be opened for evaluation.

- The product must be designed to prevent children from moving the battery:

- The battery compartment must require a tool (e.g., screwdriver, coin) to open, needing at least 0.5Nm and a 90-degree minimum rotation angle, or fasteners must engage at least two full threads.

- If opened by hand, at least two independent and simultaneous actions are required to open the battery compartment cover or door.

- If the battery compartment cover or door is secured by screws or similar fasteners, the fasteners must be retained with the cover or door to prevent loosening.

2. For products with "non-user-replaceable or movable batteries," the design must effectively prevent removal by users or children:

- The battery must not be accessible through the enclosure or similar means.

- The battery must be completely secured by welding, riveting, or similar methods.

Testing

- Pre-treatment

- Drop test

- Impact test

- Crush test

- Torque test

- Pull test

- Compression test

- Secure installation test (for non-user-replaceable batteries)

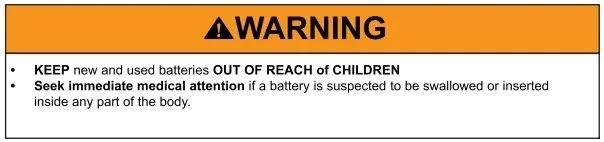

Warning Labels (on the Product)

1. If there is enough space on the product body, use label Figure 7C.1.

2. If space is insufficient, use label Figure 7C.2, and provide an explanation of the symbol in the product manual or other printed materials or tags included with the product packaging.

3. If the product body space is insufficient for labels Figure 7C.1 or Figure 7C.2, the packaging must meet the packaging warning label requirements or use a tag to include the complete packaging warning label requirements.

Warning Labels (on the Packaging)

Note: Packaging warning labels are necessary regardless of available space on the product body.

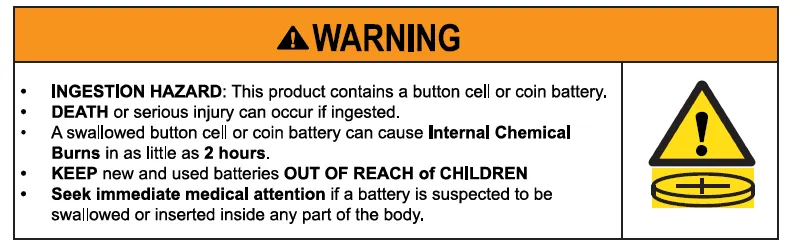

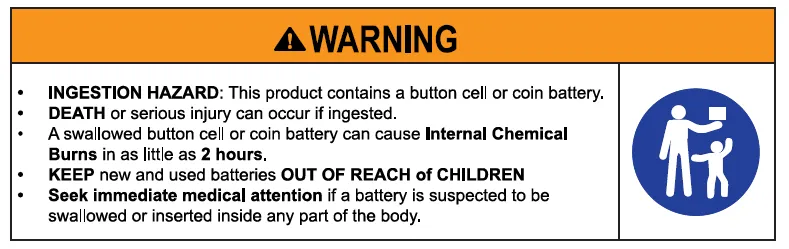

1. If the main packaging space is sufficient, use Figure 7B.1 or Figure 7B.2.

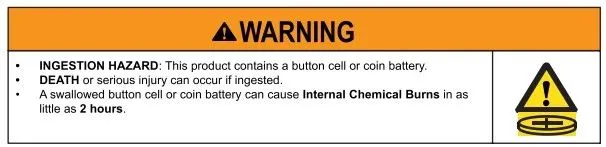

2. If the main packaging space is insufficient, use Figure 7B.3 on the main space and Figure 7B.4 on the secondary space. Using only one is not enough.

Warning Label Considerations:

- Ensure color consistency with the specific colors on the above warning labels when using multi-colored labels.

- The icon size must be at least 7mm wide and 9mm high, with the icon in Figure 7B.2 being at least 8mm in diameter.

- Markings must be in the official language of the country where the product is sold, or in English if no official language is specified.

JJRLAB Battery Testing Laboratory

JJRLAB Battery Testing Laboratory has comprehensive testing equipment and can perform complete testing and evaluation of the safety of power banks, battery packs, and cells according to standards such as IEC/EN 62133-1, IEC/EN 62133-2, UL4200a, UL 1642, ul 2054, ul 2056, UL2271, GB 31241, GB 35590, UN 38.3, etc.

Equipment:

- Battery compression test machine

- Temperature-controlled battery short-circuit test machine

- Explosion-proof box

- High-altitude low-pressure test chamber

- Battery burn test device

- Battery heavy impact test machine

- Battery drop test machine

- Glove box

- Battery internal short circuit test machine

Testing Items:

- Temperature cycling test

- Thermal shock test

- High-temperature high-humidity test

- Low-pressure test

- Vibration test

- Free drop test

- Collision test

- Compression test

- Heavy impact test

- Overcharge test

- Over-discharge test

- External short circuit test

- High-temperature discharge test

- Low-temperature discharge test

- Cycle discharge test

- Thermal abuse test

Email:hello@jjrlab.com

Write your message here and send it to us

What is FCC Class A vs. Class B?

What is FCC Class A vs. Class B?

UL Standards for Electrical Equipment

UL Standards for Electrical Equipment

Is UL Certification Required in the USA?

Is UL Certification Required in the USA?

Wireless Microphone Export Certification

Wireless Microphone Export Certification

Audio-Visual Products SNI Certification in Indones

Audio-Visual Products SNI Certification in Indones

FCC-ID: Still Needed if Module is Certified?

FCC-ID: Still Needed if Module is Certified?

FCC Certification Fees for Handheld Fans

FCC Certification Fees for Handheld Fans

FCC Certification Testing for Smart Lighting Produ

FCC Certification Testing for Smart Lighting Produ

Leave us a message

24-hour online customer service at any time to respond, so that you worry!